Diffuse scattering film, preparation method thereof and use thereof

A diffuse scattering and thin film technology, which is applied in the direction of botanical equipment and methods, applications, climate change adaptation, etc., can solve the problem of not fully reflecting the effect of diffuse scattering film, ineffective light uniformity and sun protection, film light transmittance and fog Low light intensity and other problems, to achieve the effect of reducing the intensity of direct light, reducing the focal edge phenomenon, and improving the haze of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

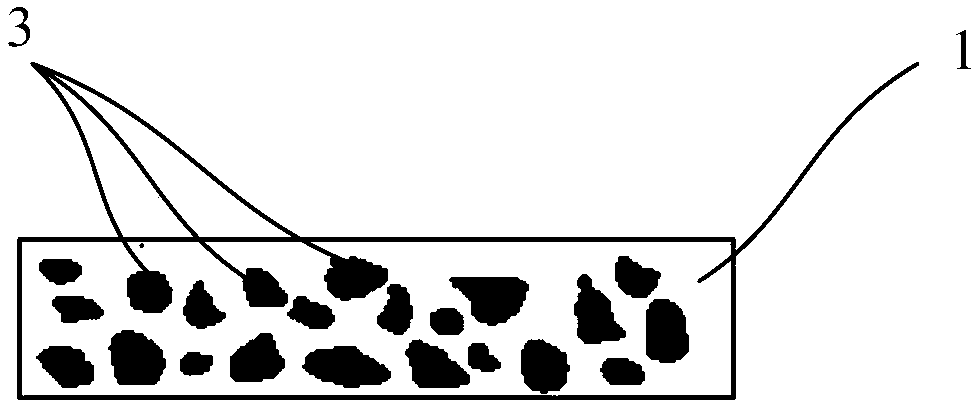

[0049] This embodiment discloses a diffuse scattering film with a thickness of 80 μm. The components of the diffuse scattering film and the contents of each component are as follows:

[0050]

[0051] The above-mentioned polyethylene is a film-grade high-transparency polyethylene grade: 2420D, produced by CNOOC Shell, with a refractive index of 1.45; the above-mentioned organic light scattering particles are made of polysiloxane (specifically, silicone elastomer) with a particle size of 2.0 μm, which is Dow Chemical company product, grade: 30-424, refractive index 1.41.

[0052] The specific production method is as follows: first mix 2 parts of organic light scattering particles 30-424 with 8 parts of film-grade high-transparency polyethylene 2420D and 0.5 parts of light stabilizer and antioxidant, and then make light-scattering masterbatch through a screw extruder. Then add the light-scattering masterbatch to the remaining film-grade high-transparency polyethylene and mix ...

Embodiment 2

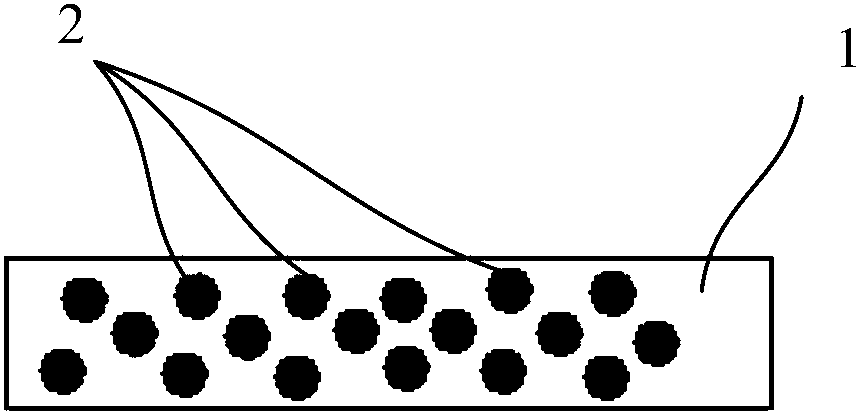

[0054] This embodiment discloses a diffuse scattering film with a thickness of 60 microns. The composition and ratio of the diffuse scattering film are as follows:

[0055]

[0056] The above-mentioned polyethylene is a film-grade high-transparency polyethylene grade: 1018CA, produced by ExxonMobil Corporation of the United States, with a refractive index of 1.45; the above-mentioned organic light-scattering particles are polysiloxane with a particle size of 1.66 microns (specifically, polymethylsilsesquioxane Alkanes) material, Momentive products, grade: Tospeal 120, refractive index 1.43.

[0057] The specific production method is: first mix 2 parts of organic light scattering particles Tospeal 120 with 8 parts of film-grade high-transparency polyethylene 1018CA and 0.5 parts of light stabilizer and antioxidant, and extrude through a screw extruder to obtain light scattering masterbatch , and then add the light-scattering masterbatch to the remaining film-grade high-trans...

Embodiment 3

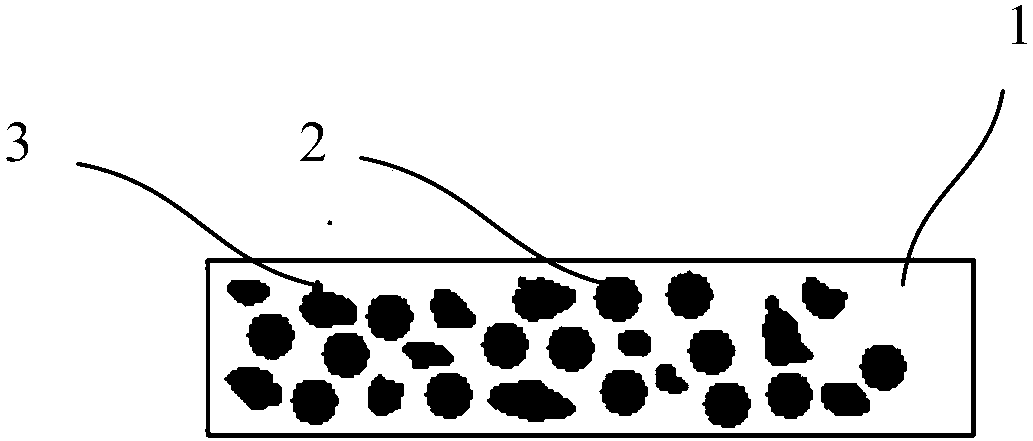

[0059] This embodiment discloses a diffuse scattering film with a thickness of 60 microns. The composition and ratio of the diffuse scattering film are as follows:

[0060]

[0061] The above-mentioned polyethylene is a film-grade high-transparency polyethylene grade: 1018CA, produced by ExxonMobil Corporation of the United States, with a refractive index of 1.45; the above-mentioned organic positive spherical light-scattering particles are polysiloxane with a particle size of 1.66 microns (specifically polymethyl sesqui Silicone) material, Momentive products, brand: Tospeal 120, refractive index 1.43. The inorganic powder is talcum powder product of Liaoning Xinda Company, brand name: SD-9689, particle size: 4.0 microns.

[0062] The specific production method is: first mix 1 part of organic light scattering particles Tospeal 120, 1 part of talcum powder SD-9689, 8 parts of film-grade high-transparency polyethylene 1018CA, and 0.5 parts of light stabilizer and antioxidant,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com