Method for reproducing heavy-duty package kraft linerboard by utilizing papermaking sludge

A technology of papermaking sludge and kraft paper, which is applied in the field of papermaking, can solve the problems of increasing production cost or processing cost, reducing paper quality, and waste of renewable resources, so as to achieve clean and environmental protection in the production process, reduce overall production costs, and reduce processing costs. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0035] A method for utilizing papermaking sludge to regenerate heavy-duty packaging kraftboard, comprising the following steps,

[0036]In the sludge collection step, the papermaking sludge generated in the papermaking process is pumped to the sludge storage tank, and the white water from the white water department of the paper mill is transported to the sludge storage tank through pipelines. The recycled water is used to dilute the papermaking sludge to a concentration of 7-10% to obtain a diluted slurry. After the papermaking sludge is diluted, the concentrated diluted slurry is easier to filter out the impurities and avoid damage to the fibers;

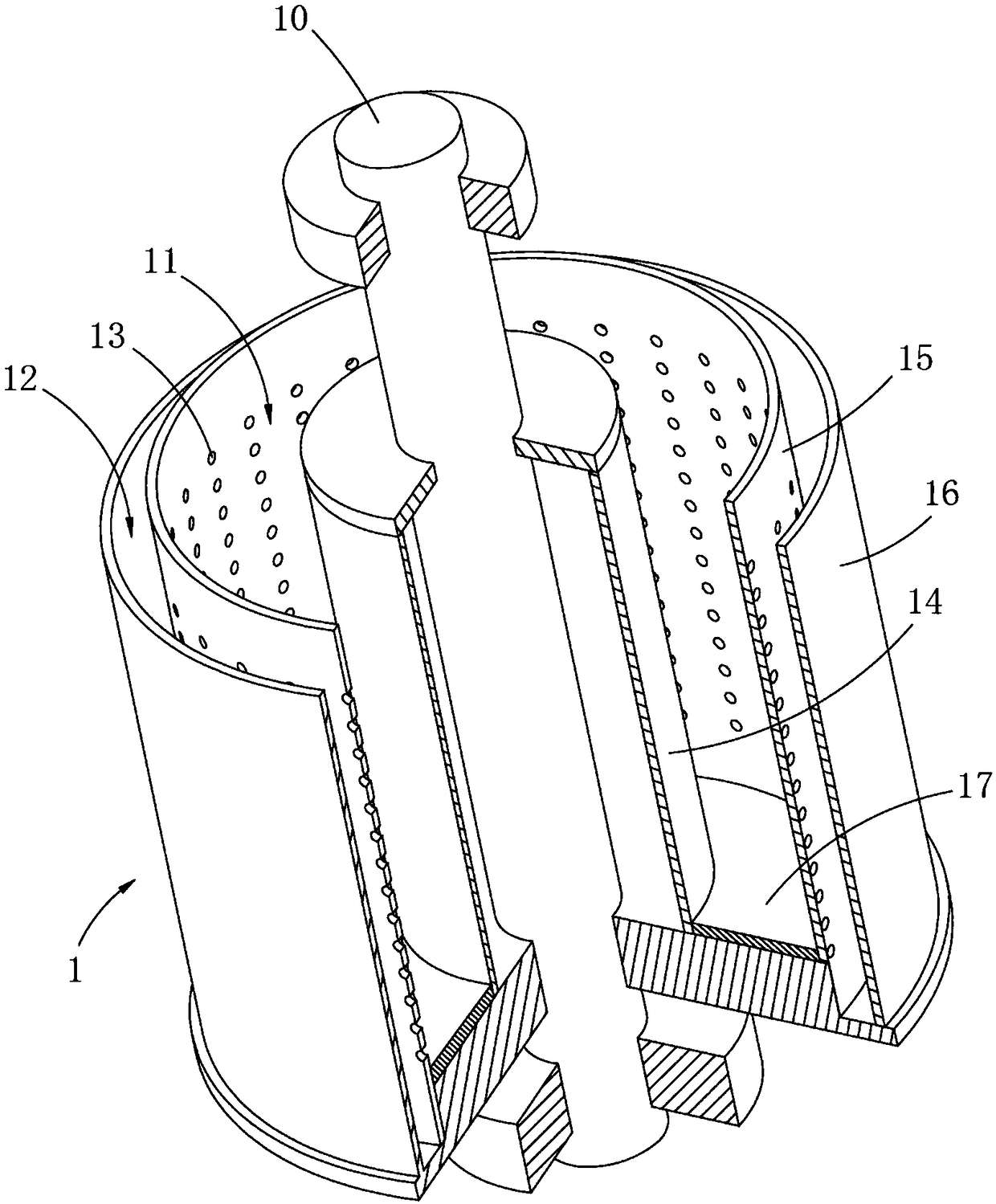

[0037] In the high-concentration deslagging step, the diluted mud is pumped to the high-consistency deslagging device. The high-consistency deslagging device is a common equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com