Garbage incineration system

A waste incineration and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of large area, high cost, unfavorable incineration, etc., and achieve the effect of reducing the occupied area and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

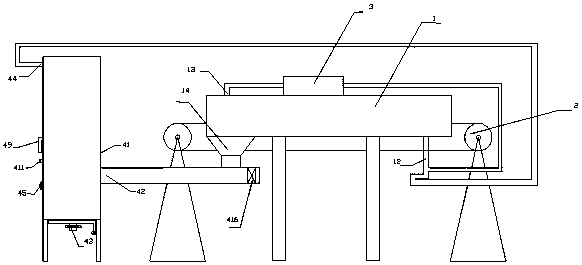

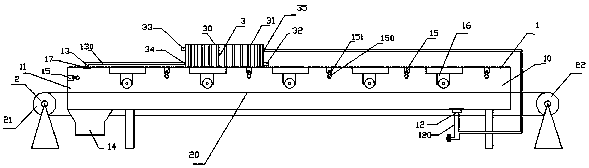

[0043] A garbage incineration system, including an incinerator and an integrated device for breaking up and drying, characterized in that: the integrated device for breaking up and drying includes a casing 1 and a conveyor 2, the casing 1 is a closed shell, and the casing 1 Including the inlet section 10 and the outlet section 11, the cross-sectional area of the outlet section 11 is larger than the cross-sectional area of the inlet section 10, the end of the inlet section 10 is provided with a feed port, the end of the outlet section 11 is provided with an outlet, and the bottom of the inlet section 10 A hot air inlet 12 is provided, a hot air outlet 13 is provided on the top of the outlet section 11, and a discharge port 14 is provided at the bottom of the outlet section 11. A plurality of blowers 15 and a plurality of breakers 16 are installed on the top, the blowers 15 and the breakers 16 are arranged at intervals, the distance between the two sides of the conveyor belt ...

Embodiment 2

[0051] On the basis of Embodiment 1, the hot air inlet 12 of the casing 1 is connected to the hot air inlet pipe 120, the hot air outlet 13 is connected to the hot air outlet pipe 130, and a heat exchanger 3 is installed on the top of the casing 1, and the heat exchanger 3 includes a casing 30 and the heat exchange coil 31, the heat exchange coil 31 is installed in the housing 30, the housing 30 is provided with a hot water inlet 32, a hot water outlet 33, an air inlet 34 and an air outlet 35, the heat exchange coil 31 One end is connected with the hot water inlet 32, the other end is connected with the hot water outlet 33, the hot air outlet pipe 130 is connected with the air inlet 34, the hot air inlet pipe 120 is connected with the air outlet 35, and the end of the outlet section 11 is also installed There are hair dryers 15.

Embodiment 3

[0053] On the basis of Embodiment 1, an air blowing device is installed at the inner bottom of the body of furnace 41. The air blowing device includes an air blowing pipe 414, an air pipe 415 and a blower 416. There are multiple air blowing pipes 414, and they are installed on the air pipe 415. Air pipe 414 is positioned at the inner bottom of body of heater 41, and air pipe 415 is positioned at outer bottom of body of heater 41.

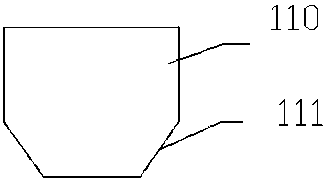

[0054] The air blowing tube 414 includes an inner tube 417, an outer tube 418 and a disc 419. The disc 419 passes through the inner tube 417 and is welded on the inner tube 417. The outer tube 418 covers the inner tube 417, and the inner tube 417 and the inner tube 417 The air pipe 415 is connected, the outer pipe 418 is a truncated cone, and the inner pipe 417 is a seamless steel pipe with two openings. The side of the outer pipe 418 is provided with an air blowing hole 420. The air blowing hole 420 is obliquely arranged on the outer pipe 418. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com