Optical detector and preparation method therefor, fingerprint recognition sensor, and display device

An optical detector and fingerprint recognition technology, applied in the fields of fingerprint recognition sensors, optical detectors and their preparation, and display devices, can solve the problem of reduced photosensitive area area, optical detector sensitivity that cannot meet requirements, photodiodes and TFT switches. Large area and other problems, to achieve the effect of reducing the size, increasing the area of the photosensitive area, and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

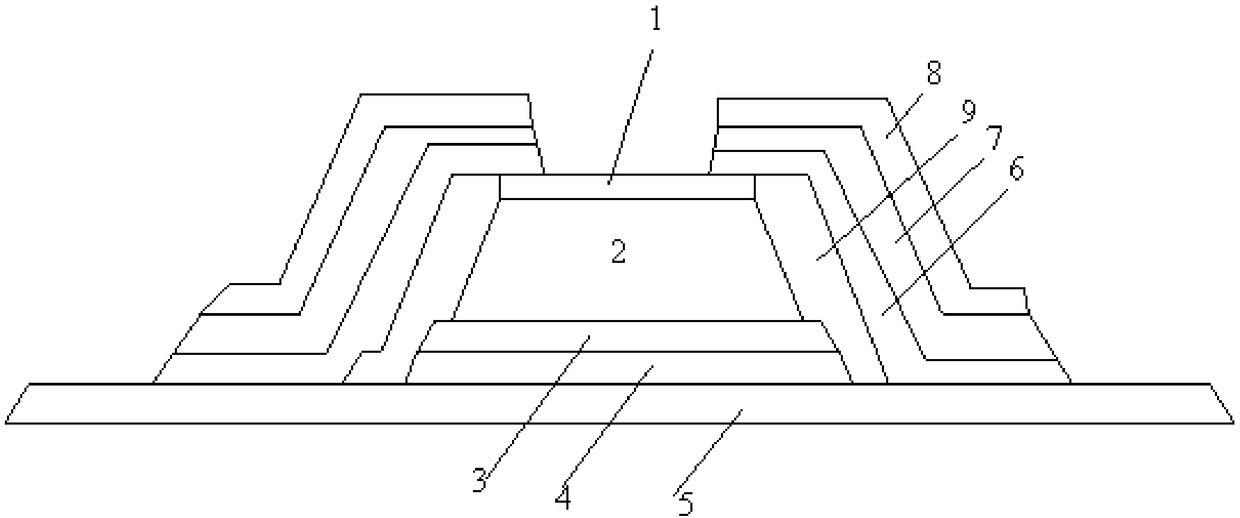

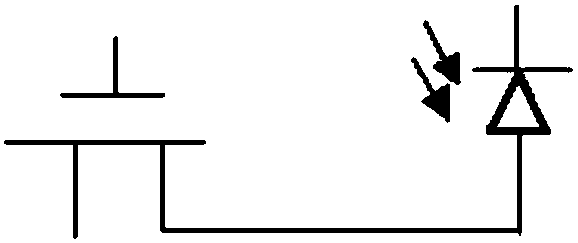

[0040] Figure 1a Schematic diagram of the structure of the optical detector provided in Embodiment 1 of the present invention; Figure 1b for Figure 1a Block diagram of the optical detector shown; see Figure 1a with Figure 1b , the optical detector provided by Embodiment 1 of the present invention includes: a stacked structure of a first electrode 1, a photoelectric conversion layer 2, a second electrode 3, a first insulating layer 4, and a third electrode 5 that are sequentially stacked; the optical detector It also includes an active layer 6 , a gate insulating layer 7 and a gate 8 .

[0041] Wherein, the first electrode 1 and the second electrode 3 are used as the two working electrodes of the photoelectric conversion layer 2, and the first electrode 1 is used as the light-incident electrode. The so-called light-incidence electrode refers to the electrode on which the light signal is incident. A transparent electrode that allows light signals to enter. That is, the fi...

Embodiment 2

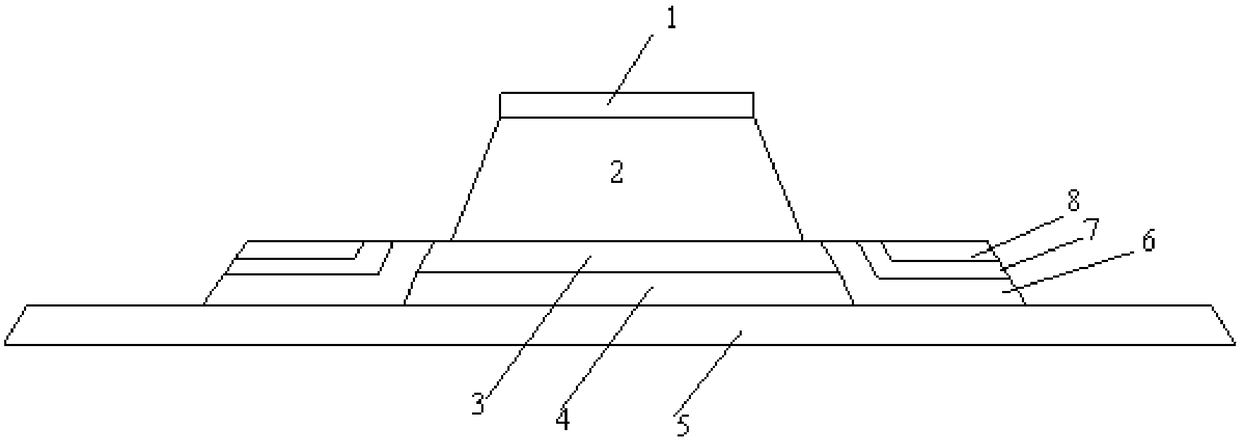

[0048] figure 2 The structural representation of the optical detector provided for embodiment 2 of the present invention; Please refer to figure 2 The optical detector provided by Embodiment 2 of the present invention is similar to the optical detector provided by Embodiment 1, and also includes a first electrode 1, a photoelectric conversion layer 2, a second electrode 3, a first insulating layer 4, and a third electrode 5 , the active layer 6 , the gate insulating layer 7 and the gate 8 , since their respective positional relationships and functions have been described in detail in the above-mentioned embodiment 1, they will not be repeated here.

[0049]Only the differences between this embodiment and the above-mentioned Embodiment 1 will be described below. In this embodiment, the second electrode 3 and the third electrode 5 serve as one and the other of the source and the drain, respectively. Specifically, such as figure 2 As shown, the active layer 6 is electricall...

Embodiment 3

[0052] image 3 It is a flow chart of the preparation method of the optical detector provided in Example 3 of the present invention. see image 3 , the preparation method of the optical detector provided by the present embodiment comprises the following steps:

[0053] S1, preparing a first electrode, a photoelectric conversion layer, a second electrode, a first insulating layer, and a third electrode that are sequentially stacked on the substrate.

[0054] S2, preparing an active layer, the active layer is electrically connected to the first electrode and the third electrode, and is insulated from the photoelectric conversion layer and the second electrode;

[0055] S3, preparing a gate insulating layer on the active layer.

[0056] S4, preparing a gate on the gate insulating layer.

[0057] The above step S1 specifically includes but is not limited to:

[0058] Form a third electrode material layer, a first insulating layer material layer, a second electrode material la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com