Production method of light sensitive diode

A technology of photosensitive diode and manufacturing method, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc. The problem of leakage current, increasing the area of the photosensitive area, the effect of the best photosensitive sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

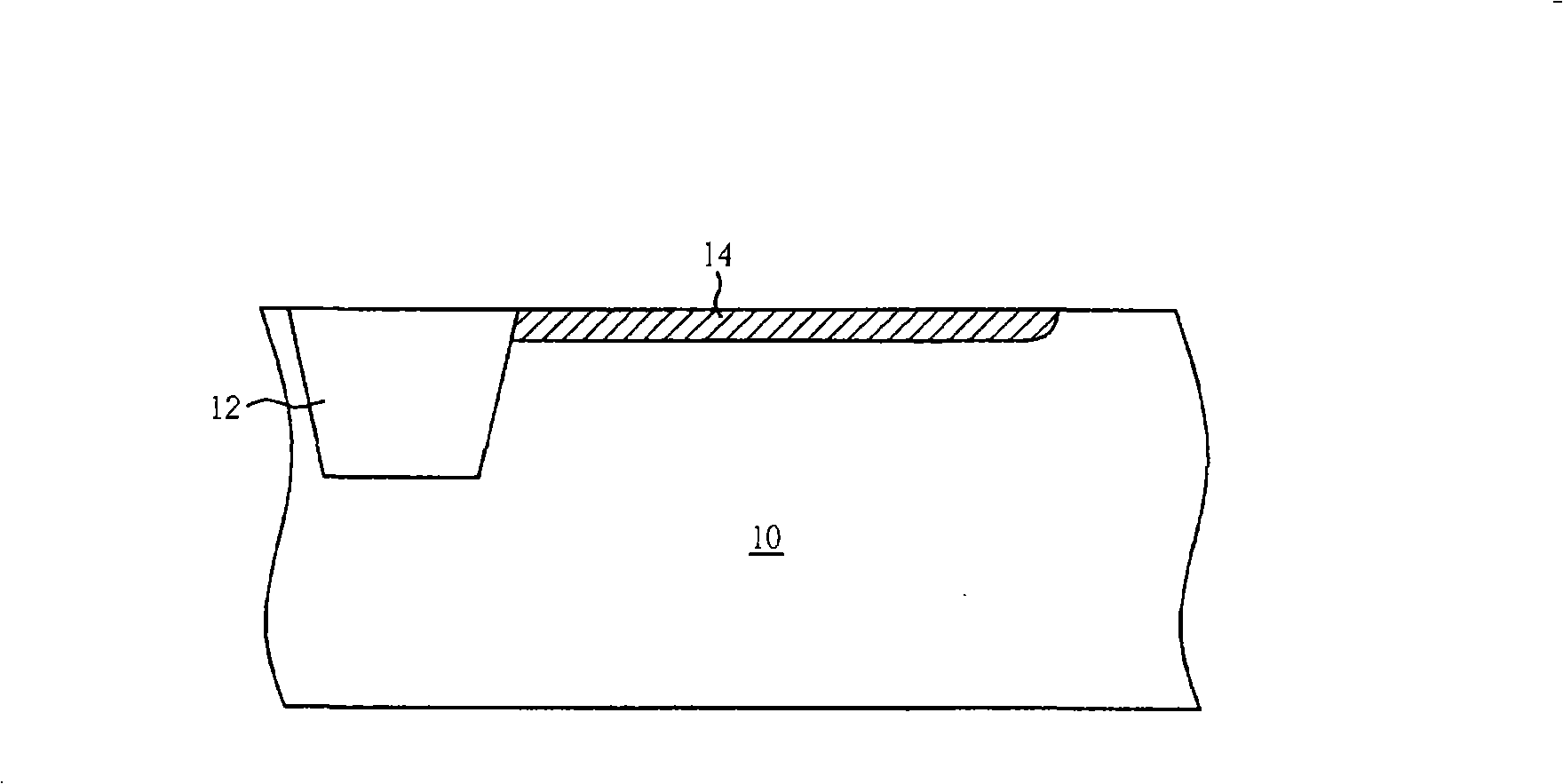

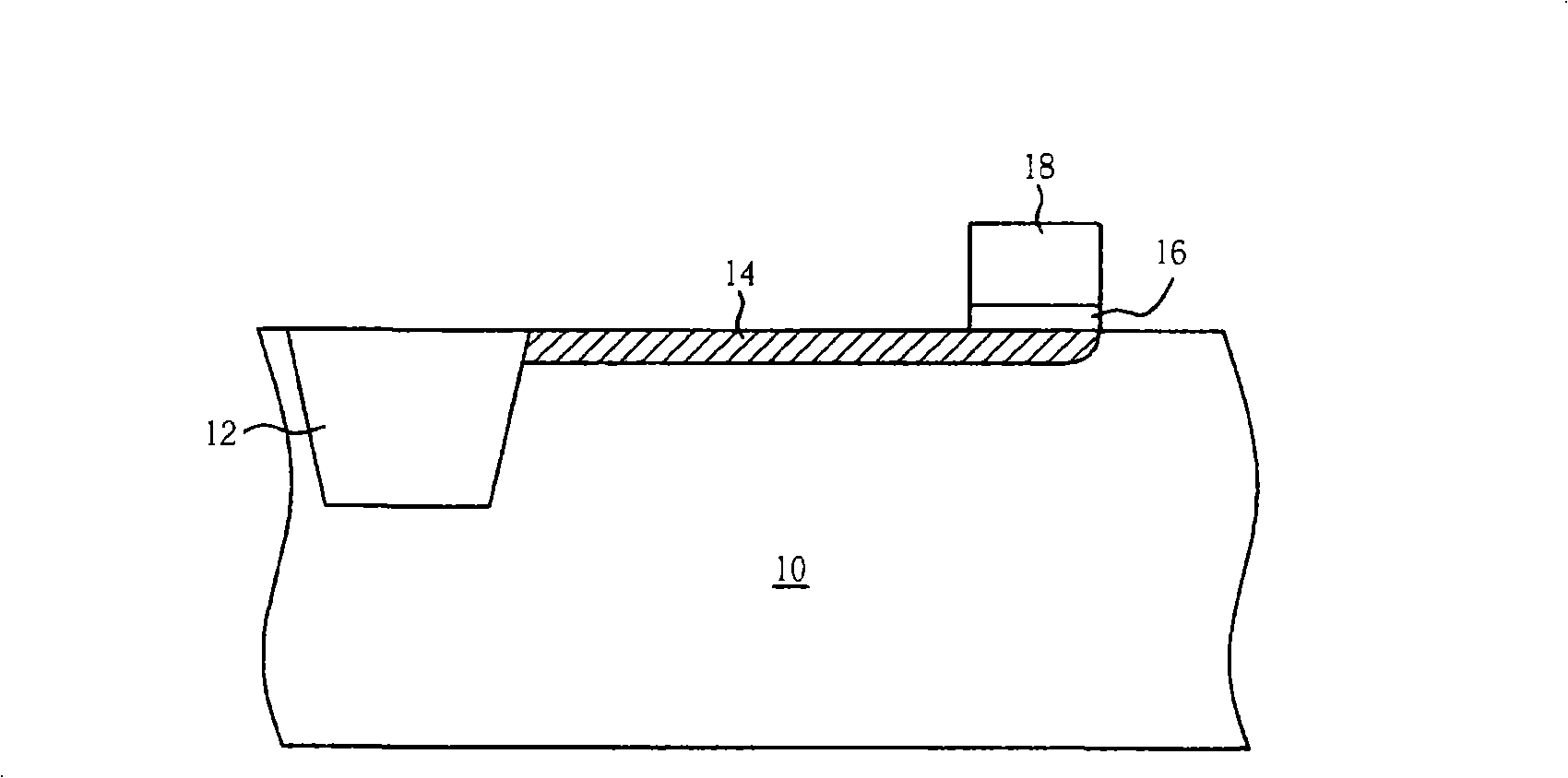

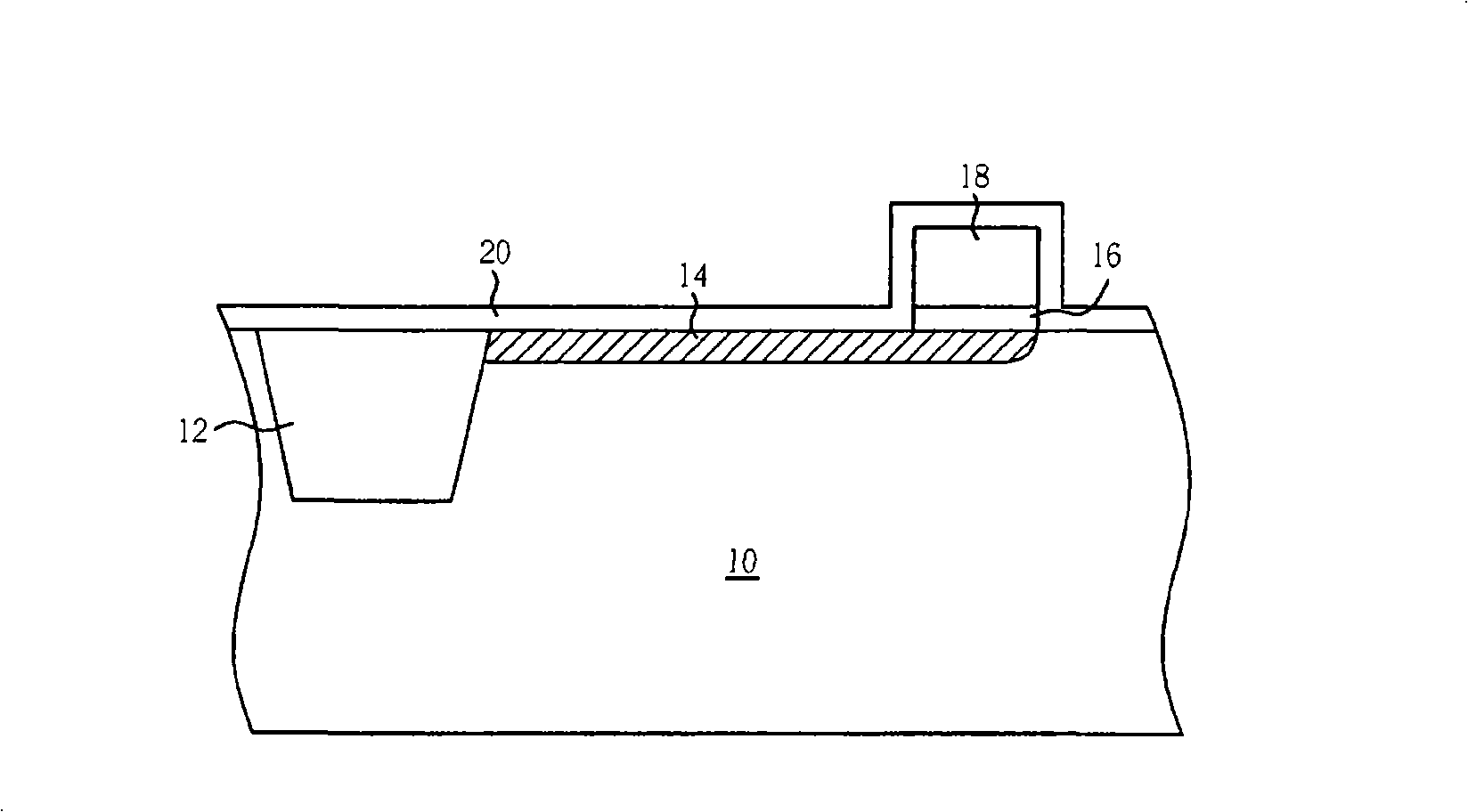

[0052] Please refer to Figure 15 to Figure 19 , Figure 15 to Figure 19 It is a schematic diagram of a method for fabricating a photosensitive diode according to a preferred embodiment of the present invention.

[0053] Such as Figure 15 As shown, firstly, a substrate 40 is provided, which at least includes a P-type doped well 41 and an STI structure 42 formed in the substrate 40 . As is well known to those skilled in the art, for example, the doping well process can be performed first, and then at least one trench (not shown) is formed in the substrate 40, and an insulating layer (not shown) is completely covered and filled on the surface of the substrate 40. trenches, and STI structures 42 are then formed in substrate 40 using chemical mechanical polishing. Wherein, the STI structure 42 is used to isolate each pixel unit of the active pixel sensor from each other, and it can also be replaced by other insulating structures such as a field oxide layer (FOX). Then P-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com