Preparation method of chromium tantalum titanium alloy sputtering target, chromium tantalum titanium alloy sputtering target and application

A tantalum-titanium alloy and sputtering target technology, which is applied in the field of sputtering targets, can solve the problems of inclusion of pores, difficult to achieve density, uneven alloy composition, etc., and achieves high density, convenient operation and excellent machining performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

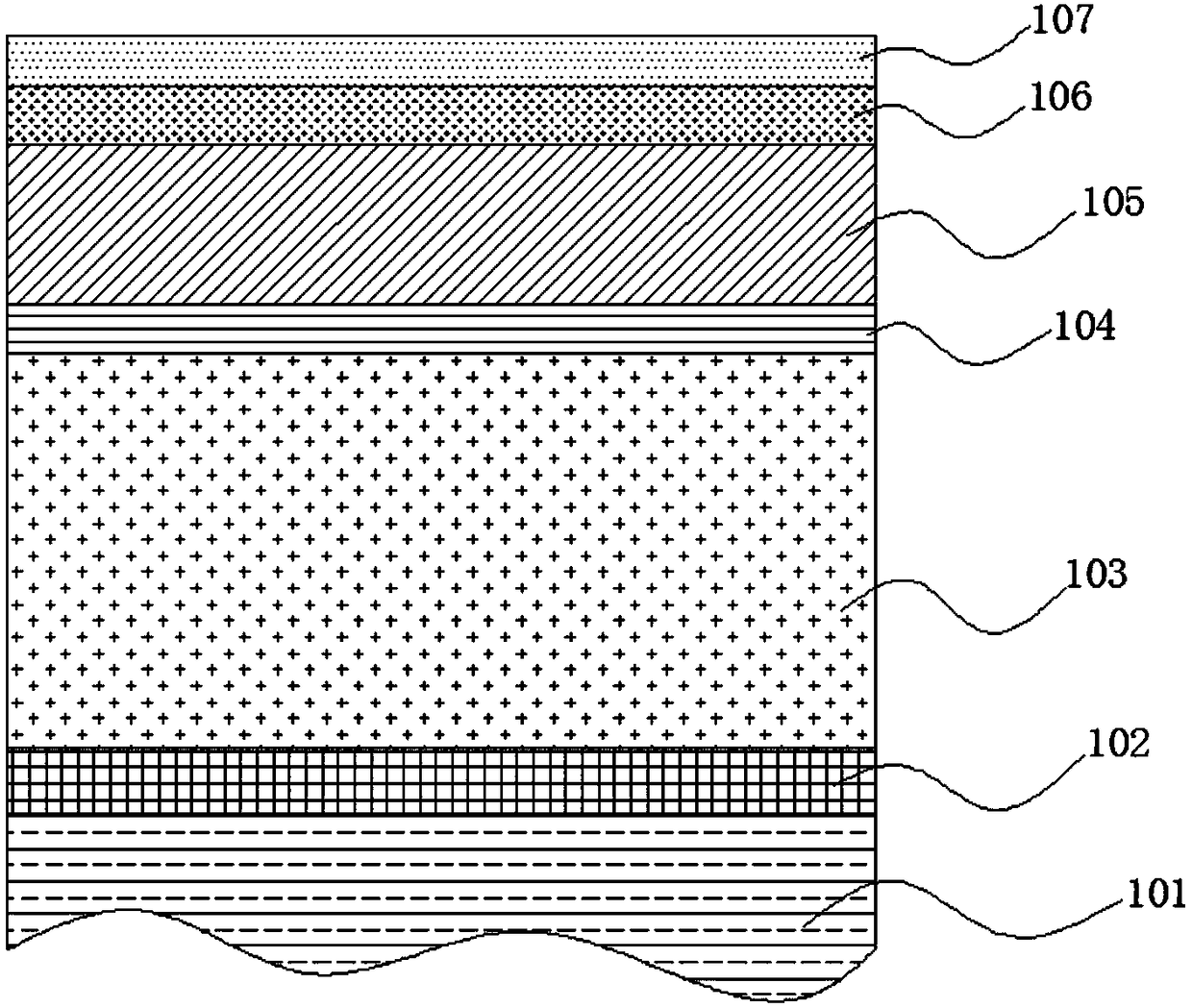

[0039] According to one aspect of the present invention, the present invention provides a kind of preparation method of chromium-tantalum-titanium alloy, comprising the following steps:

[0040] (a) providing a mixture of chromium powder, tantalum powder and titanium powder, and carrying out cold isostatic pressing to obtain a blank;

[0041] (b) carry out vacuum degassing to blank;

[0042] (c) performing hot isostatic pressing on the vacuum-degassed billet to obtain a chromium-tantalum-titanium alloy sputtering target.

[0043] The preparation method of the chromium-tantalum-titanium alloy sputtering target material provided by the present invention is to prepare the chromium-tantalum-titanium alloy sputtering target by sequentially subjecting the mixture of chromium powder, tantalum powder and titanium powder to cold isostatic pressing, vacuum degassing and hot isostatic pressing The prepared chromium-tantalum-titanium alloy sputtering target not only has a density higher ...

Embodiment 1

[0082] This embodiment provides a chromium-tantalum-titanium alloy sputtering target, which is prepared according to the following steps:

[0083] (S) Mix chromium powder, tantalum powder and titanium powder in a powder mixer, press argon gas protection, the argon pressure is 0.02MPa, then turn on the powder mixer at 10r / min, the powder mixing time is 20h, and obtain chromium powder , a mixture of tantalum powder and titanium powder;

[0084] (A) Put the mixture of chromium powder, tantalum powder and titanium powder into the rubber sleeve, tamp it tightly, seal the rubber sleeve, and then put the rubber sleeve into a cold isostatic press at a temperature of 25°C and a cold isostatic pressure of 150MPa , keep the pressure for 20min, take out the rubber sleeve from the cold isostatic press, and remove the rubber sleeve to obtain the blank;

[0085] (B) Put the billet into a stainless steel sheath, seal it, then put the stainless steel sheath into a heat treatment furnace and h...

Embodiment 2

[0088] This embodiment provides a chromium-tantalum-titanium alloy sputtering target, which is prepared according to the following steps:

[0089] (S) Mix chromium powder, tantalum powder and titanium powder in a powder mixer, press argon protection, the argon pressure is 0.06MPa, then turn on the powder mixer at 4r / min, the powder mixing time is 30h, and obtain chromium powder , a mixture of tantalum powder and titanium powder;

[0090] (A) Put the mixture of chromium powder, tantalum powder and titanium powder into the rubber sleeve, tamp it tightly, seal the rubber sleeve, and then put the rubber sleeve into a cold isostatic press at a temperature of 25°C and a cold isostatic pressure of 250MPa , keep the pressure for 10min, take out the rubber sleeve from the cold isostatic press, and remove the rubber sleeve to obtain the blank;

[0091](B) Put the billet into a stainless steel sheath, seal it, then put the stainless steel sheath into a heat treatment furnace and heat it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com