Large-scale aluminum alloy bent member molded surface precision measurement and milling method

A precision detection, aluminum alloy technology, applied in metal processing mechanical parts, mechanical counter/curvature measurement, milling machine equipment, etc., can solve problems such as troublesome operation, achieve product accuracy, save manufacturing cost and time cost, and one-time pass rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

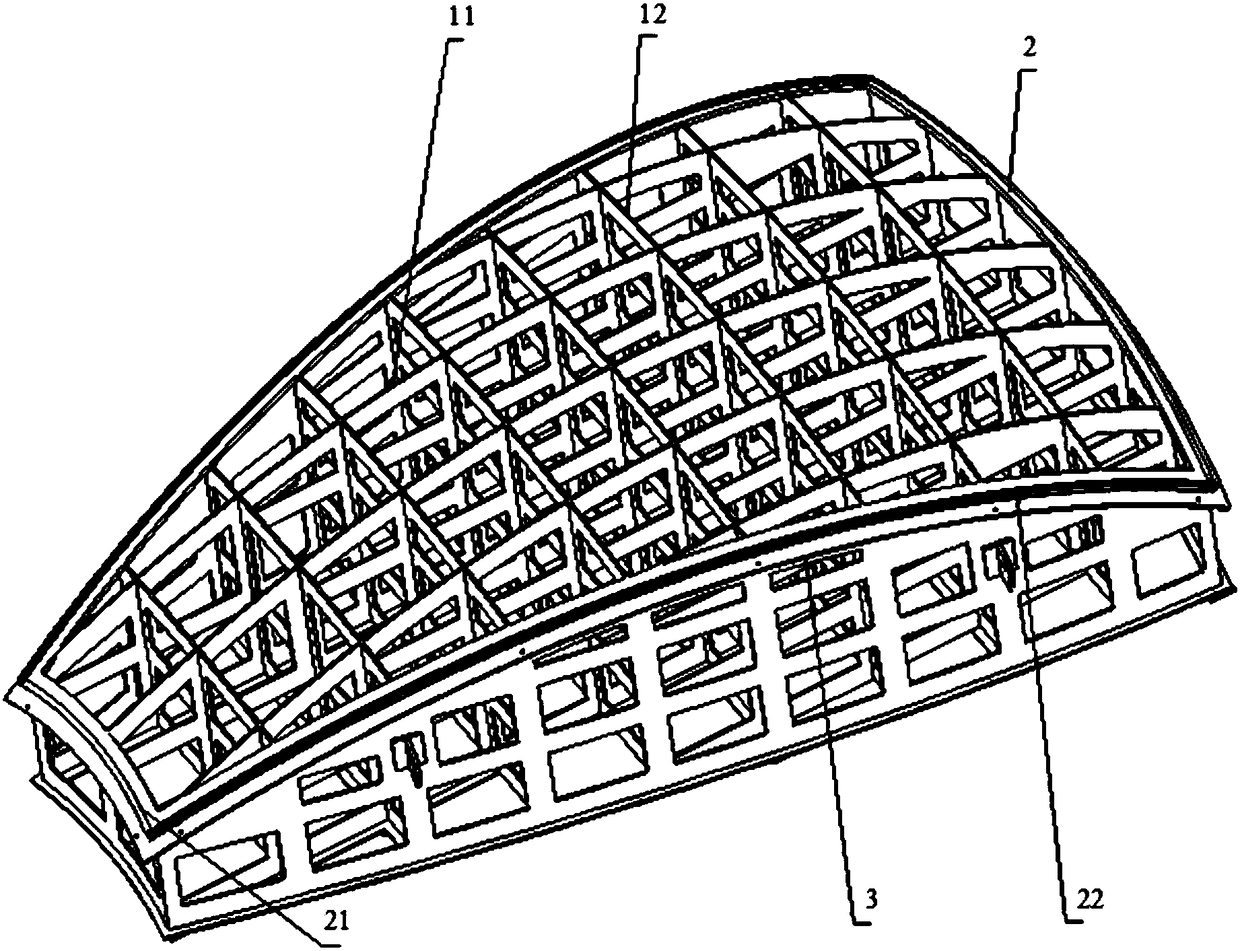

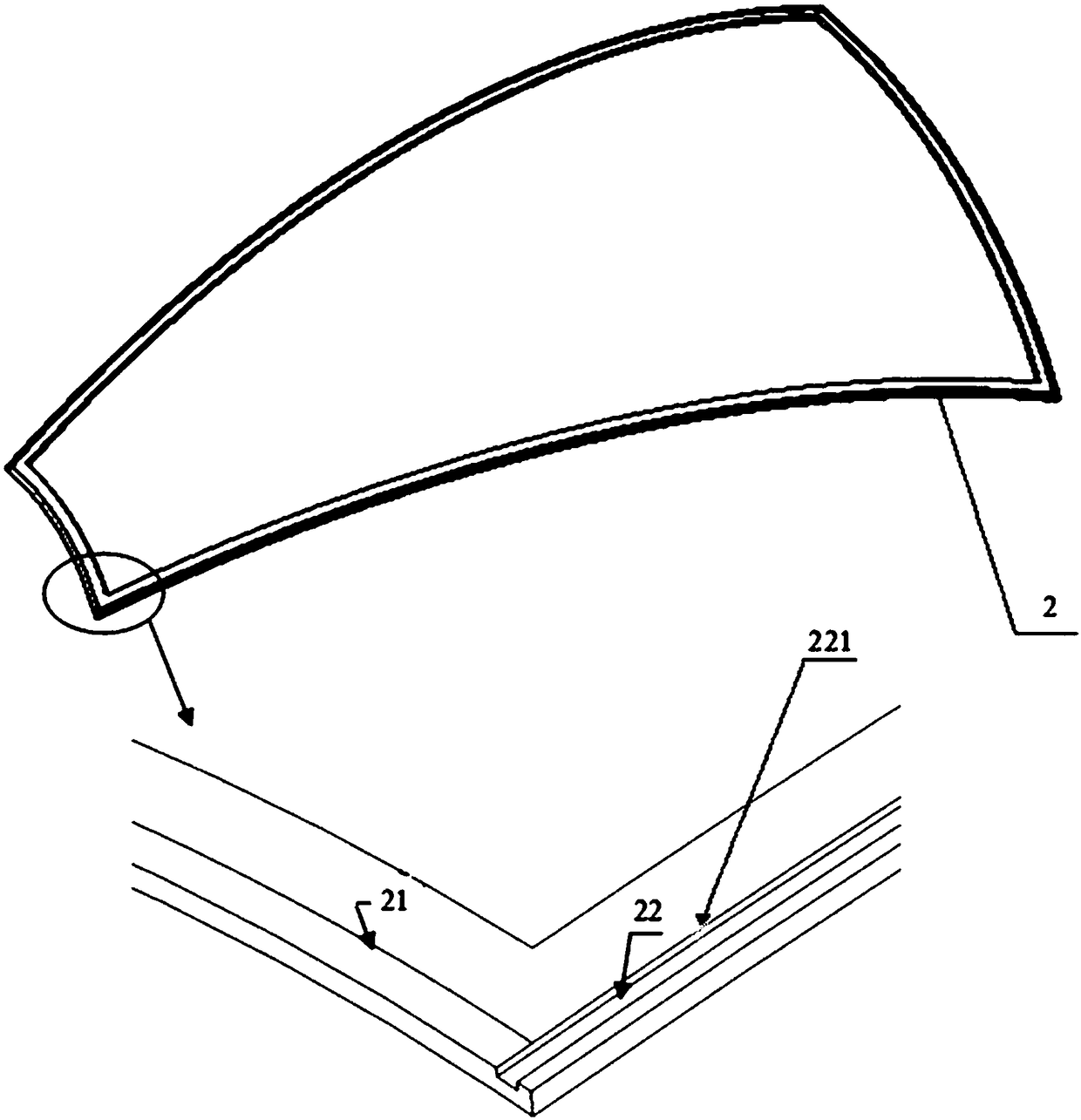

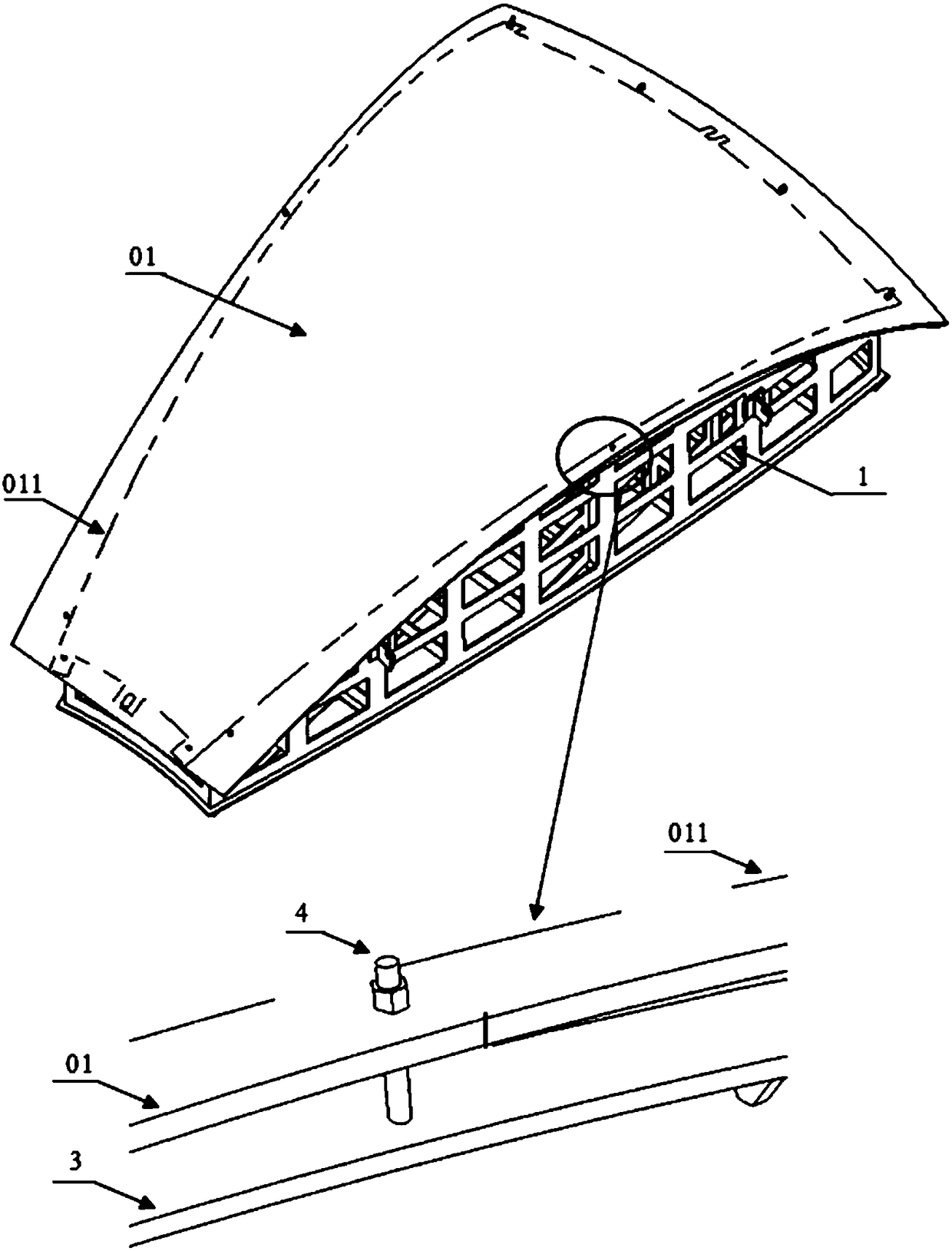

[0032] The present invention first provides a composite tool (composite device) for surface accuracy detection and margin milling of large thin-walled components, such as figure 1 As shown, its basic features include that the tooling has both a thin-walled component profile accuracy detection function and a peripheral margin milling function; the tooling is formed by welding a card board with an integral frame, and the card board includes a horizontal card board and a longitudinal card board. The tooling mentioned before the accuracy test is mainly composed of a card board 1, a peripheral narrow panel 2, a knife slot 22 and a theoretical line 21, and a pressure plate 3 arranged on the peripheral narrow panel 2, such as figure 1 . The horizontal and vertical pallets are made of 10mm thick steel plates. In order to achieve weight reduction while ensuring sufficient strength and rigidity, a hole is opened in the middle of the pallet. Weld 75mm×18mm (width×thickness) narrow profile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com