Wood board grinding and straightening device

A straightening device and plank technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problem of low efficiency of manual grinding, and achieve the effect of increasing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

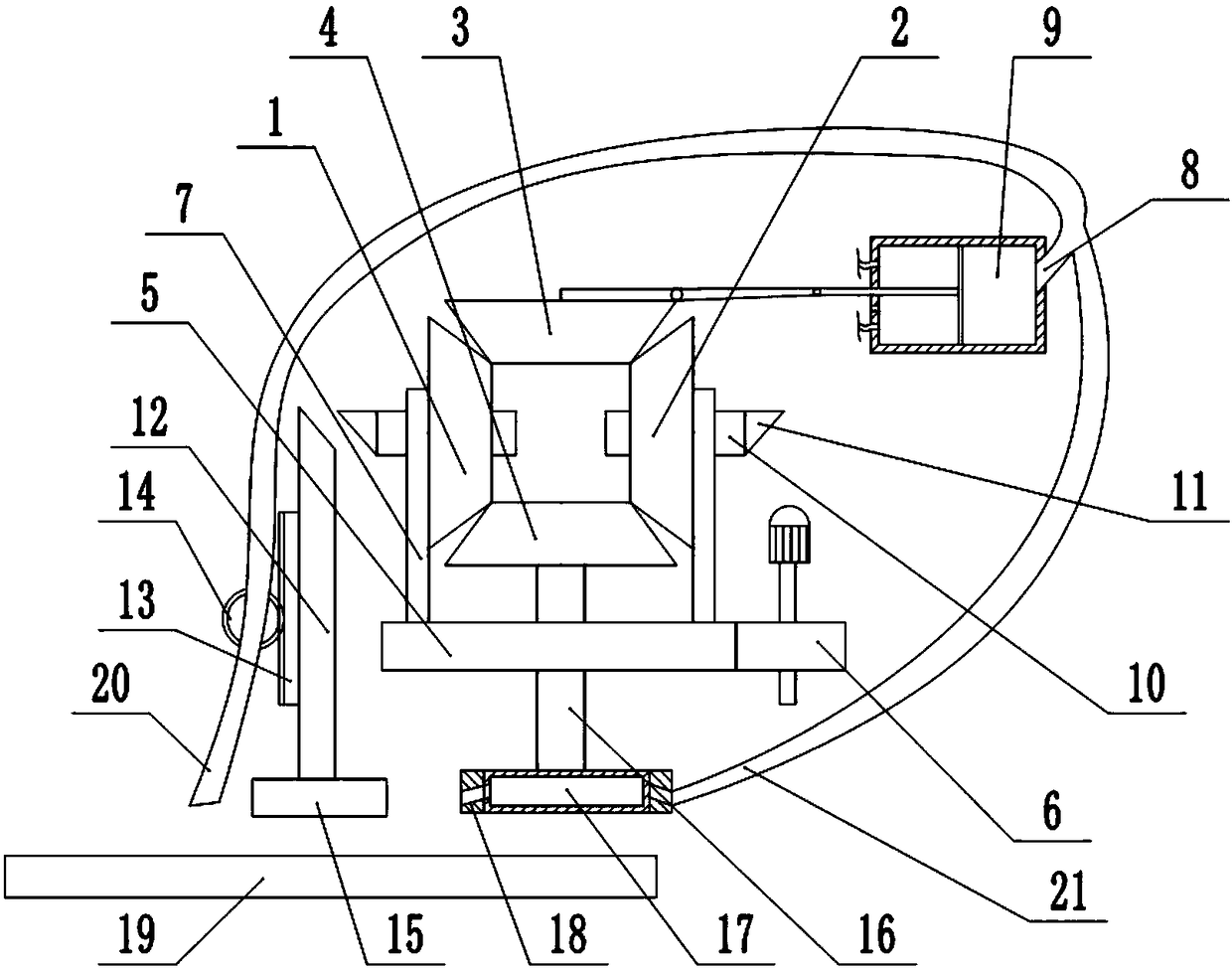

[0027] The reference signs in the accompanying drawings of the specification include: the first bevel gear 1, the second bevel gear 2, the third bevel gear 3, the fourth bevel gear 4, the driven gear 5, the driving gear 6, the planet carrier 7, the intake port 8. Piston barrel 9, reciprocating screw rod 10, wedge block 11, wedge rod 12, second rack 13, second gear 14, pressure plate 15, pole 16, grinding disc 17, sleeve 18, workbench 19, the first Two gas outlets 20, the first gas outlet 21.

[0028] Such as figure 1 As shown, the plank grinding and straightening device includes a frame, on which a driven gear 5 is rotatably connected, and the upper end of the driven gear 5 is fixedly connected with a planetary carrier 7, and the planetary carrier 7 includes a first bracket on the left side and a first bracket on the right side. The second bracket, the first bracket and the second ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap