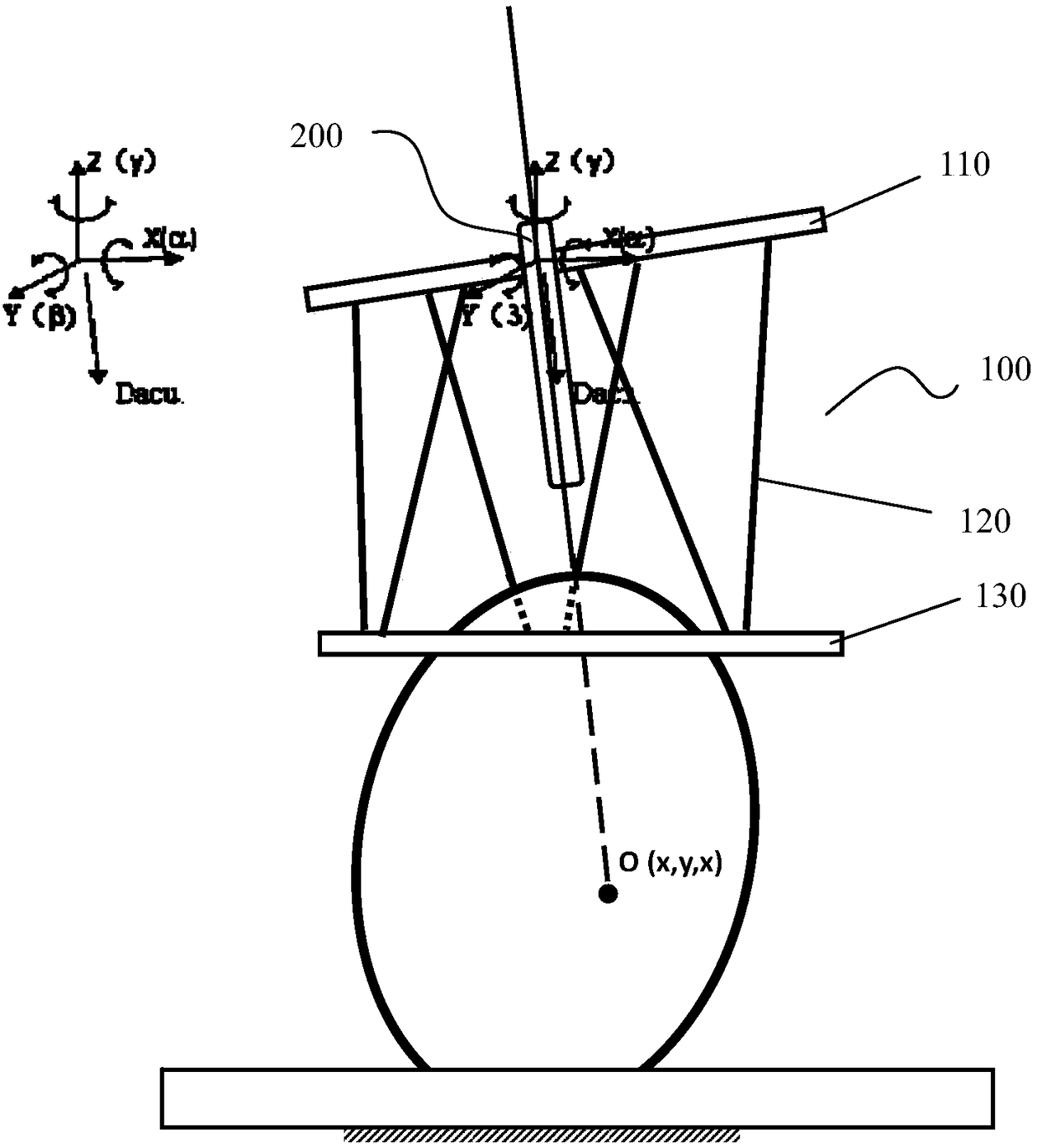

Spatial positioning directing actuation system, and 3D printing machine and method

A space positioning and actuation system technology, applied in the fields of medical treatment and 3D printing, can solve problems such as mechanical structure accumulation errors, major surgical wounds, long action stroke errors, etc., and achieve the effect of small size, accurate positioning, and wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

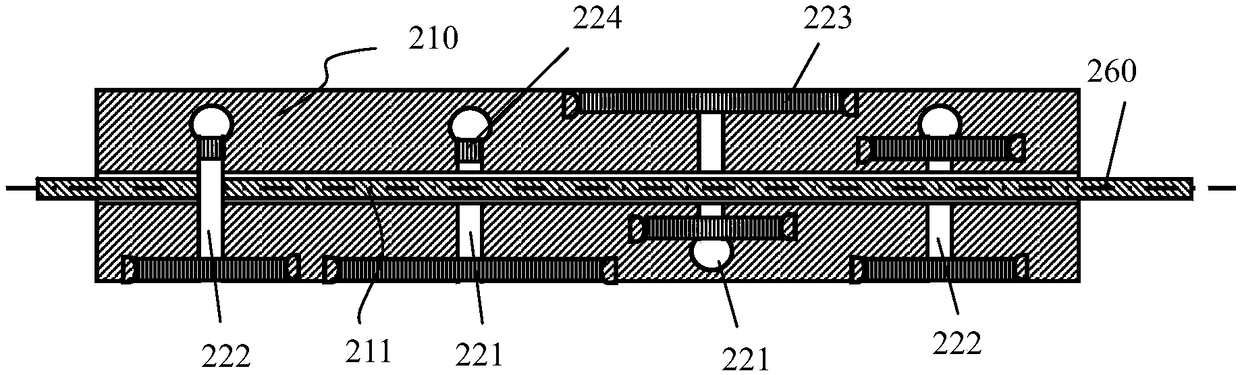

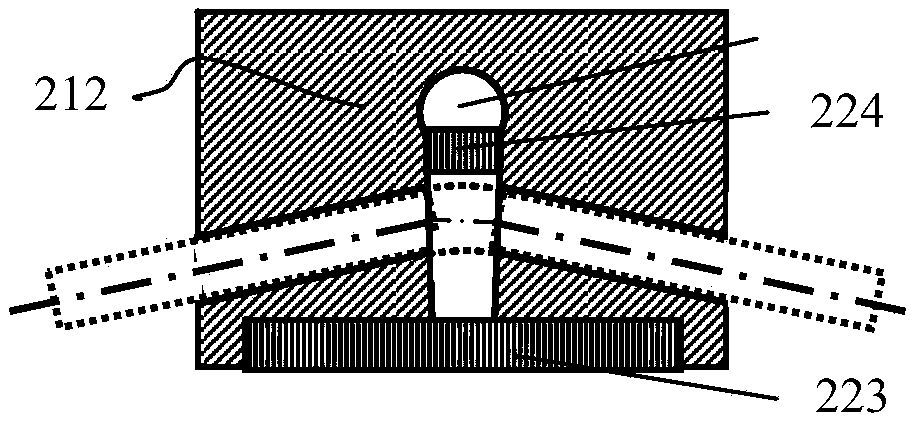

[0094] Such as figure 2 As shown, in this embodiment, the driving part 213 and the clamping part 212 are an integrally formed structure, and the driving part 213 includes one or more driving groups, and the driving group includes opposite slot positions in the radial direction. The two driving slots 221 , the clamping portion 212 includes two clamping slots 222 with the same notch positions in the radial direction, and the two clamping slots 222 are respectively located at both ends of the driving portion 213 along the axial direction. Preferably, the clamping groove 222 is not limited to the above-mentioned arrangement position, and can also be located at other positions, for example, between a plurality of driving groups and the like. When the clamping driver 210 is stretched or compressed, the groove walls of the single driving groove 221 and the groove walls of the single clamping groove 222 will move away from or approach each other, so that the inner diameter of the pas...

Embodiment 2

[0097] This embodiment is a modification of the structure provided in Embodiment 1. Such as Figure 7 As shown, in this embodiment, the clamping part 212 and the driving part 213 are obtained by assembling, including two clamping parts 212 respectively arranged at both ends of the driving part 213 along the axial direction, and the clamping part 212 can be directly tightened. It is fixedly installed on the driving part 213, and can also be indirectly fastened and installed on the driving part 213 through other structures, such as an outer sleeve, etc.

[0098] Such as Figure 5 , Figure 6 As shown, in this embodiment, the clamping portion 212 includes a clamping box 231 , an engaging member 232 , an opening and closing elastic member, and an opening and closing switch 235 . One or more tapered holes are arranged in the clamping box 231, and the engaging member 232 is installed in the tapered holes. Such as Figure 5 As shown, in the locked state, the moving part 260 and ...

Embodiment 3

[0101] This embodiment is a modification of the structure provided in Embodiment 2. Such as Figure 8 , Figure 9 As shown, the on-off switch 235 has an electromagnet 241 structure with a mandrel 242, and the mandrel 242 is a magnet structure and is connected with the first elastic member 233, and the core is driven by controlling the power on and off of the electromagnet 241. The up and down movement of the shaft 242 further drives the deformation of the first elastic member 233 to complete the movement conversion of the engaging member 232 between the unlocked position and the locked position. preferably as Figure 10 , Figure 11 As shown, the opening and closing switch 235 is an electromagnet 241 structure without a mandrel 242, and the first elastic member 233 itself is a magnet, which directly attracts or releases the first elastic member 233 through a magnetic field to complete the alignment of the engaging member 232. drive. Preferably, as Figure 12 , Figure 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com