Trackless type triangle hanging basket

A triangular hanging basket, trackless technology, used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of uneven workers' proficiency and responsibility, difficulty in manually dragging the track, and large walking safety risks. The effect of reducing the weight of the hanging basket, simplifying the walking procedure and convenient walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

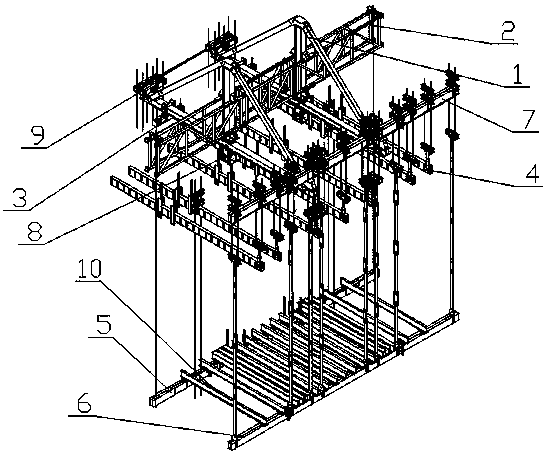

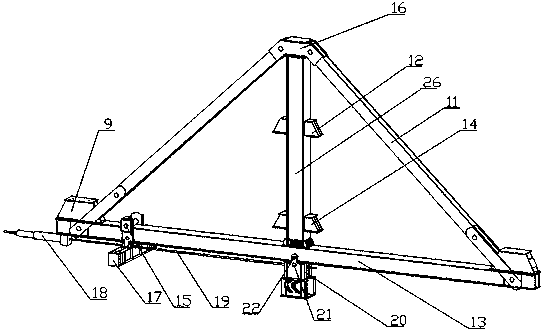

[0025] The specific implementation, structure, features and functions of the trackless triangular hanging basket proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

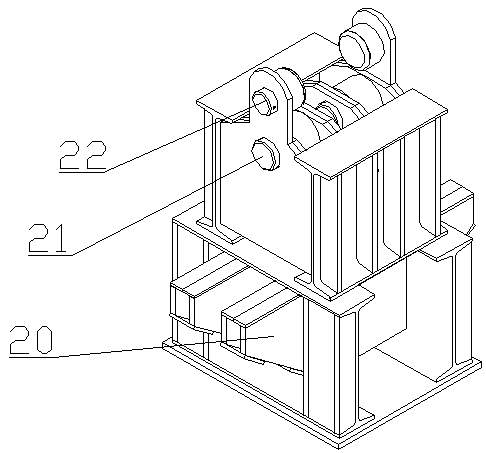

[0026] see Figure 1 to Figure 7 , the trackless triangular hanging basket of the present invention includes a main truss system, an anti-hanging system, a support system 8, and a bottom basket system. The bottom of the main truss system is equipped with an anti-hanging system, a support system 8, and a bottom basket system, wherein: the main truss system Including two triangular main trusses 1 arranged at both ends of the transverse connection truss 2 and the front upper beam 7 at the front end, each triangular main truss 1 includes a column 26, a column cap 16, a cable-stayed steel belt 11, a main longitudinal beam 13, a rear The anchor 9 and the column 26 are detachably supported on the main longitudinal beam 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com