Vacuum air-tight sealed SMD-UV-LED (surface mounted ultraviolet light-emitting diode)

A SMD-UV-LED, hermetic packaging technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low fluorescence efficiency, difficult to miniaturize, etc., and achieve the effect of high heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

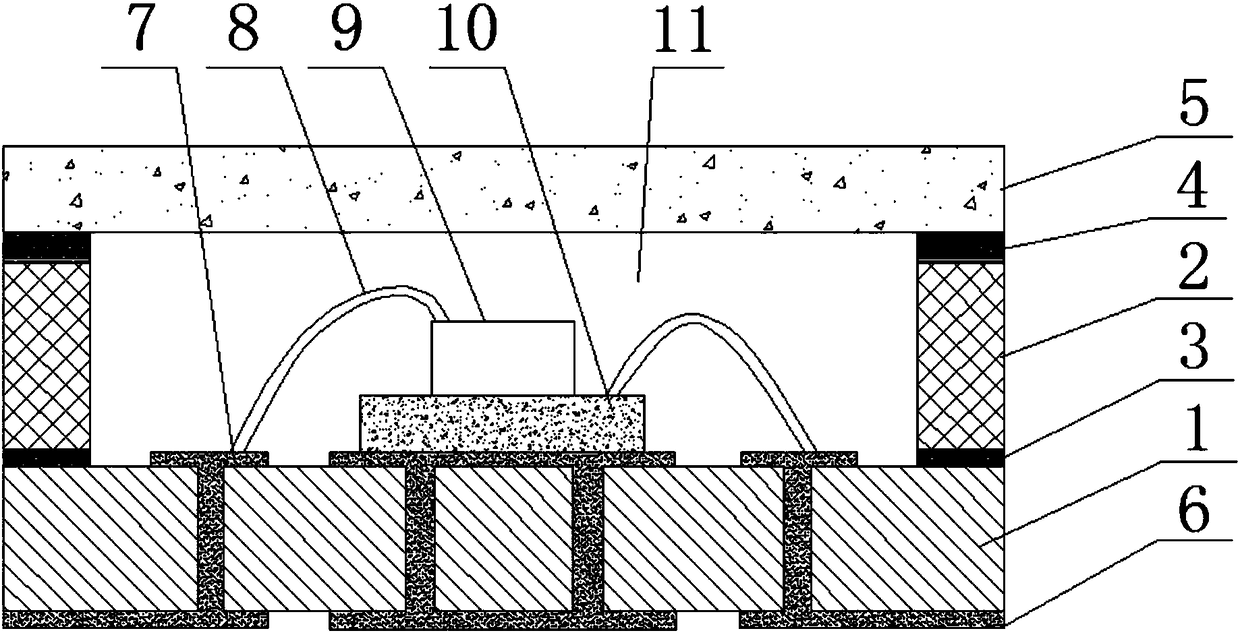

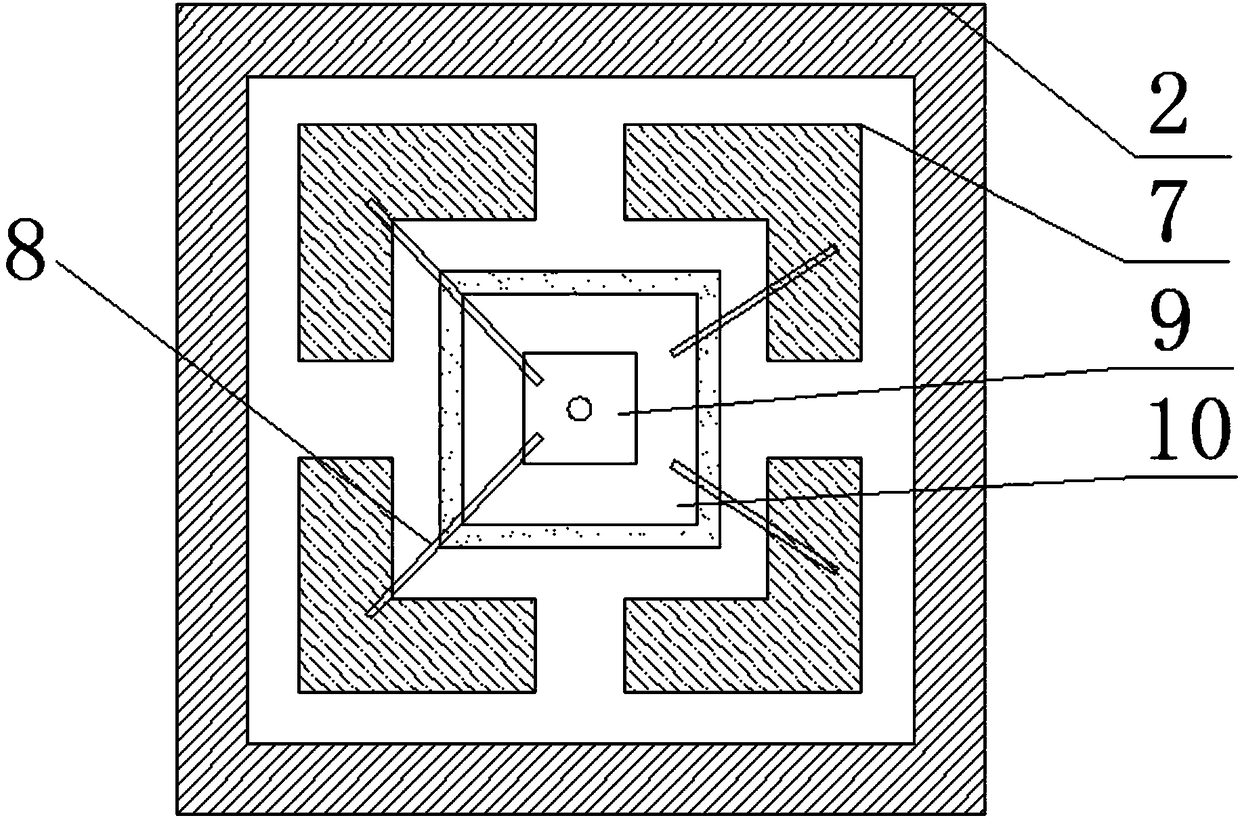

[0034] The present invention provides such Figure 1~4 and Figure 5 It is a flow chart of the preparation process of the low-temperature sealing welding method of the present invention; Figure 6 Shown in the preparation process flow chart of laser or parallel sealing welding method of the present invention:

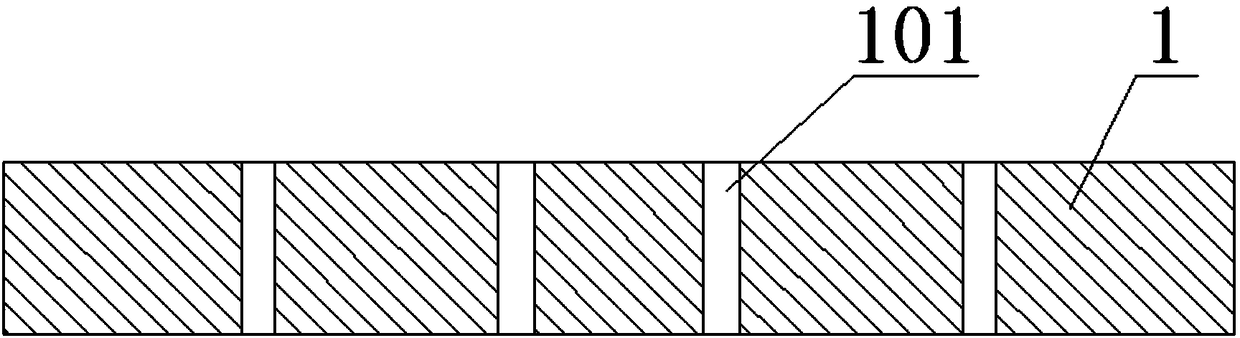

[0035] A vacuum airtight SMD-UV-LED, including a substrate 1, four groups of metal frames 2 are symmetrically installed around the top edge of the substrate 1, and the bottom of the metal frame 2 and the edge top of the substrate 1 are provided. There is a first sealing layer 3, the top of the metal frame 2 is connected to the bottom edge around the glass window 5, and a second sealing layer is arranged between the top of the metal frame 2 and the bottom edge around the glass window 5 4. Both the first sealing layer 3 and the second sealing layer 4 are hermetically sealed, the substrate 1, the metal frame 2 and the glass light window 5 form a relatively sealed cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com