Composite multilayer filter structures used as subcomponents in general acoustics and electronics

A multi-layer filtration, electronic product technology, applied in the direction of layered products, electrical components, electronic equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Description of the preferred embodiment

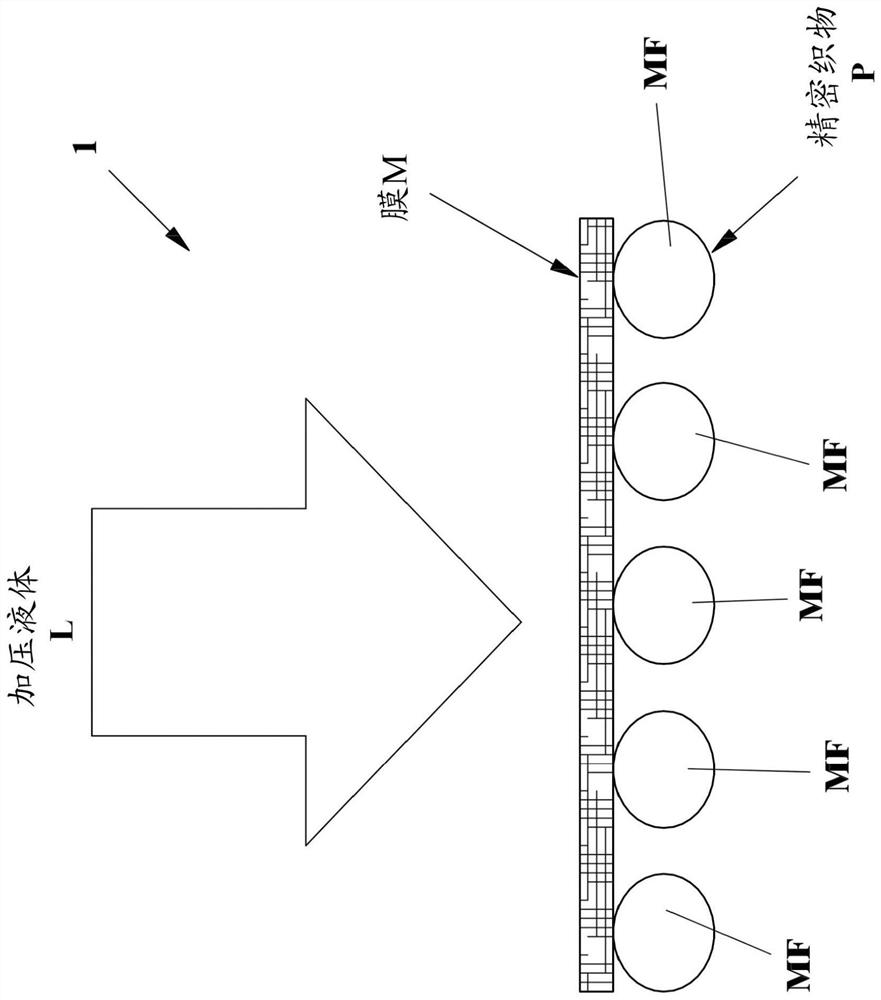

[0023] Referring to the above figures, the composite filter structure according to the present invention comprises as a first major component a precision fabric T comprising uniform "meshes" or openings (e.g. made of synthetic monofilaments and having a square mesh configuration ).

[0024] A very uniform mesh structure that is consistent throughout the entire fabric, together with its high mechanical strength and processability, make this precision monofilament fabric material T the ideal solution for filtration base materials.

[0025] These very homogeneous fabric materials have more constant properties than conventional multifilament fabrics in terms of their weight and thickness, surface properties and temperature behavior.

[0026] Uniformity of properties is maintained along the entire fabric roll from batch to batch.

[0027] Furthermore, the fabric T according to the invention is manufactured with very narrow manufact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com