Active carbon adsorption regenerator and waste gas treatment line equipped with same

A waste gas treatment and regenerator technology, applied in gas treatment, filter regeneration, combustible gas purification, etc., can solve the problems of long time consumption, complicated activated carbon process, and reduced adsorption performance of activated carbon to achieve good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

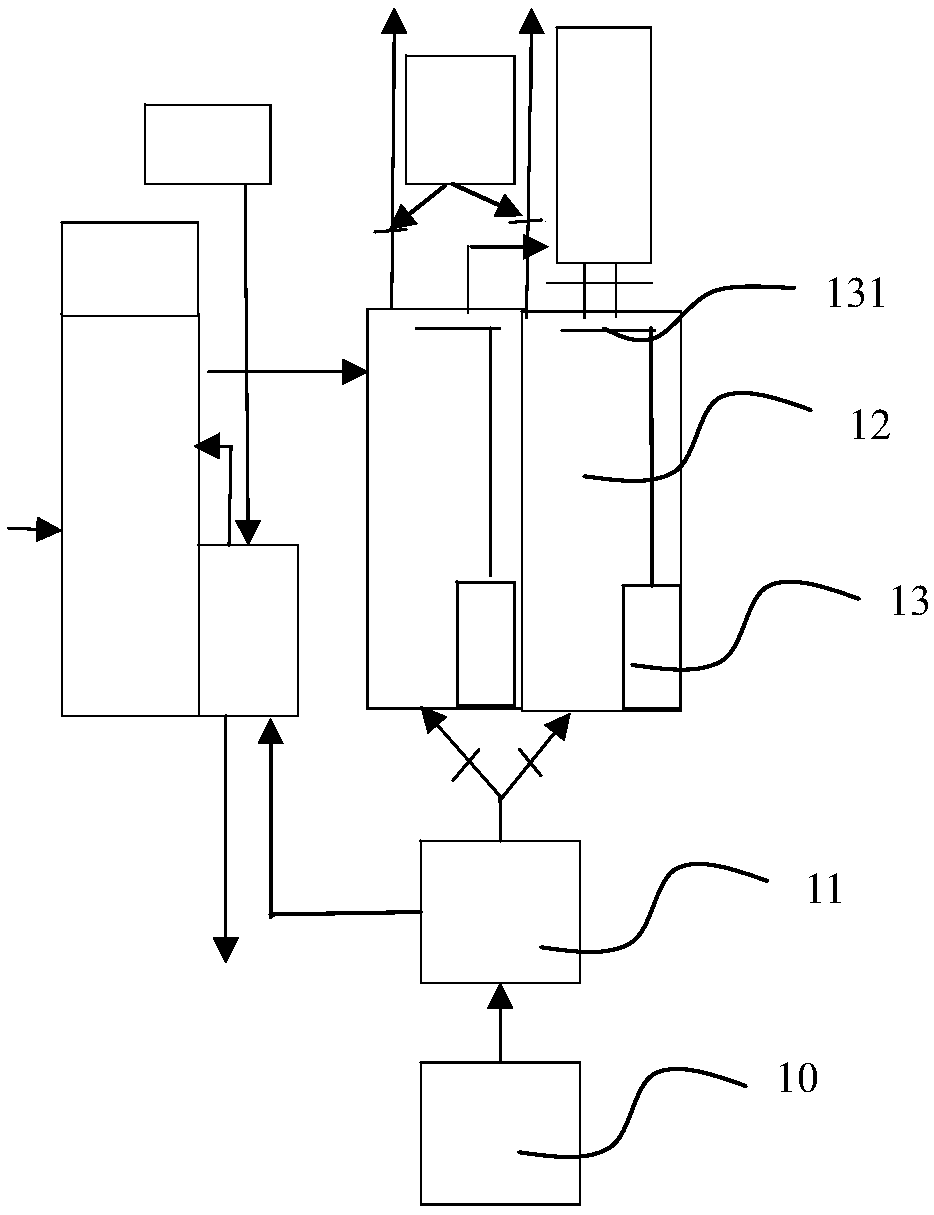

[0022] An adsorption regenerator provided by the present invention includes an adsorption chamber, the lower part of the adsorption chamber is provided with an air inlet, the upper part of the adsorption chamber is provided with an exhaust port and an air return port, and the exhaust port and the air return port are provided with a second A valve; the air return port is connected with a condenser 2 or a shower 4 . The exhaust port is used to discharge the treated exhaust gas, and the air return port is used to guide the waste gas in the process of regenerating activated carbon into other waste gas treatment equipment. An activated carbon storage frame is arranged in the adsorption chamber, and activated carbon is placed in the activated carbon storage frame. A steam generator 10 is connected to the lower part of the adsorption chamber. The steam generator 10 includes a liquid storage chamber, and a heating device is arranged in the liquid storage chamber. The steam generator 1...

Embodiment 2

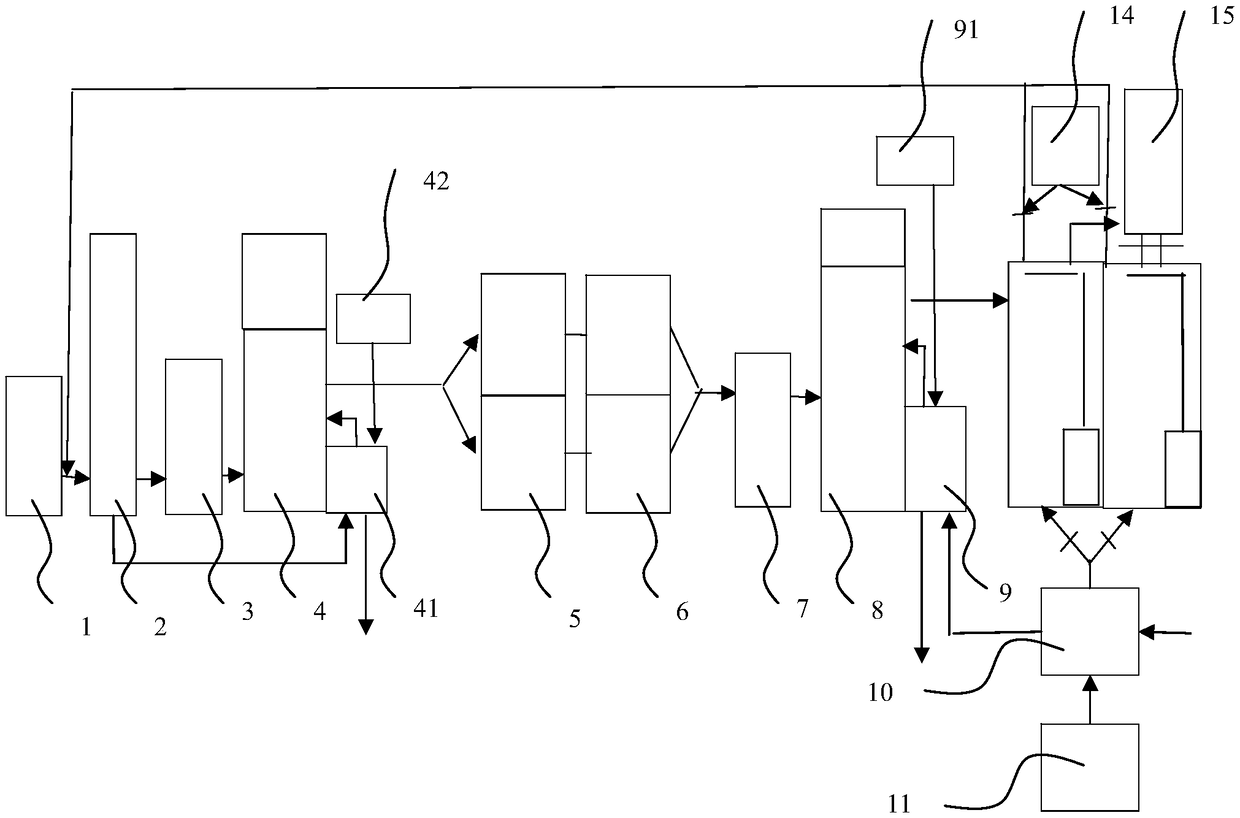

[0026] The present invention also provides a waste gas treatment line equipped with the above-mentioned adsorption regenerator, including a condenser 2, a shower 4 and a photocatalytic oxidizer 5 connected in sequence, and the air inlet of the adsorption regenerator is connected to the photocatalytic oxidizer 5 The exhaust pipe of the adsorption regenerator is connected to the condenser 2. There are two adsorption regenerators and photocatalytic oxidizers 5, and both the adsorption regenerators and the photocatalytic oxidizers 5 are connected in parallel. The lower part of the shower 4 is provided with a first concentration and drying equipment 41. The first concentration and drying equipment 41 includes a first waste liquid collection chamber, and the liquid inlet of the first waste liquid collection chamber is connected with the sprayer 4 and the condenser. 2 are connected; the upper part of the first waste liquid collection chamber is provided with a first drug feeding port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com