Method of enhancing sludge dehydration performance

A sludge dehydration and performance technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the uncertain environmental and ecological risks, difficult microorganisms, degradation and utilization of dewatered sludge, etc. problem, to achieve the effect of important application value, low impact on environment and ecology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for enhancing sludge dewatering performance, which specifically includes the following steps:

[0045] Adjusting the pH value: Weighing the wet sludge, adjusting the pH value of the wet sludge to 6.5; wherein, the specific steps for adjusting the pH value of the wet sludge are, first, using a pH meter to measure the pH value of the wet sludge; secondly According to the measurement results, add 0.1 mL of weak base with a concentration of 0.1 mol / L to the wet sludge. After stirring evenly, measure the pH value of the wet sludge. When the pH value of the wet sludge is 6.5, stop adding Weak base;

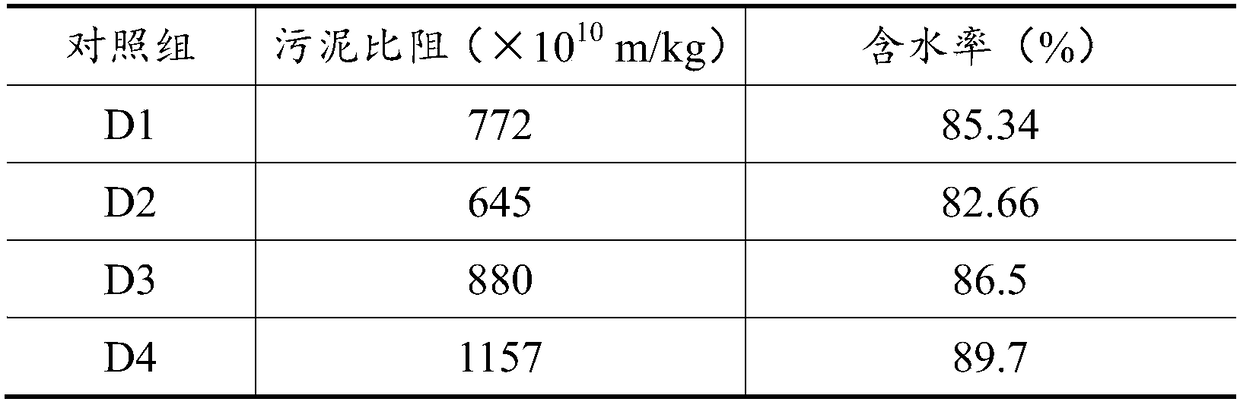

[0046] Enzyme pretreatment: first add 4g lysozyme to the wet sludge after pH adjustment, stir evenly, then shake and react at a temperature of 25°C and an oscillation frequency of 155rpm for 2h, then add 1g protease, stir evenly, Shake and react at 45°C and 155rpm for 2 hours. After the reaction is completed, the sludge specific resistance of th...

Embodiment 2

[0049] This embodiment provides a method for enhancing sludge dewatering performance, which specifically includes the following steps:

[0050] Adjusting the pH value: Weighing the wet sludge, adjusting the pH value of the wet sludge to 6.5; wherein, the specific steps for adjusting the pH value of the wet sludge are, first, using a pH meter to measure the pH value of the wet sludge; secondly According to the measurement results, add 0.1 mL of weak base with a concentration of 0.1 mol / L to the wet sludge. After stirring evenly, measure the pH value of the wet sludge. When the pH value of the wet sludge is 6.5, stop adding Weak base;

[0051] Enzyme pretreatment: first add 4g lysozyme to the wet sludge after pH adjustment, stir evenly, then shake and react at a temperature of 25°C and an oscillation frequency of 155rpm for 2h, then add 2g protease, stir evenly, Shake and react at 45°C and 155rpm for 2 hours. After the reaction is completed, the sludge specific resistance of th...

Embodiment 3

[0054] This embodiment provides a method for enhancing sludge dewatering performance, which specifically includes the following steps:

[0055] Adjusting the pH value: Weighing the wet sludge, adjusting the pH value of the wet sludge to 6.5; wherein, the specific steps for adjusting the pH value of the wet sludge are, first, using a pH meter to measure the pH value of the wet sludge; secondly According to the measurement results, add 0.1 mL of weak base with a concentration of 0.1 mol / L to the wet sludge. After stirring evenly, measure the pH value of the wet sludge. When the pH value of the wet sludge is 6.5, stop adding Weak base;

[0056] Enzyme pretreatment: first add 4g lysozyme to the wet sludge after pH adjustment, stir evenly, shake and react for 2 hours at a temperature of 25°C and an oscillation frequency of 155rpm, then add 3g protease, stir evenly, Shake the reaction at 45°C and 155rpm for 2 hours. After the reaction is completed, the sludge specific resistance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com