A method for improving the stability of steel slag aggregates

A stable, steel slag technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor stability of steel slag, achieve waste reuse, reduce production costs, high strength and hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for improving the stability of steel slag aggregates, the specific steps are as follows:

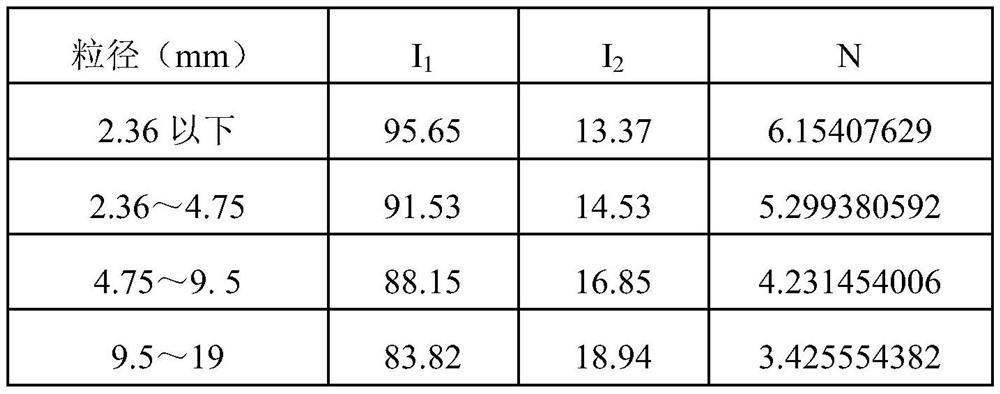

[0030] (1) Classify the steel slag particles after crushing and iron selection, and divide them into group I below 2.36mm, group II at 2.36-4.75mm, group III at 4.75-9.5mm, group IV at 9.5-19mm, and group V at 19-37.5mm These five gears. Two samples of 5 kg were taken from each grade of steel slag, one group was used as the experimental group, and the other group was used as the blank control group. The two groups of samples were placed in the carbonization box or carbonization kettle and spread evenly, and the carbonization time was selected as 21d.

[0031] (2) The carbonization intensity of the carbonization box or carbonization kettle in the experimental group was set to 3MPa·h, 7MPa·h, 12MPa·h, 22MPa·h, 54MPa·h respectively, and the corresponding CO 2 The partial pressure strengths are 0.0059MPa, 0.00139MPa, 0.0238MPa, 0.0437MPa and 0.1071MPa respectively. The rel...

Embodiment 2

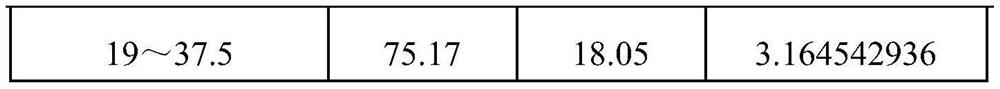

[0043] The steps of embodiment 2 are basically the same as those of embodiment 1, except that the carbonization intensity of the steel slag of the experimental group I to V is respectively set to 6MPa h, 12.5MPa h, 25MPa h, 50MPa h, 125MPa h h, CO in the corresponding carbonization box or carbonization kettle 2 The partial pressure strengths are 0.0119MPa, 0.0248MPa, 0.0496MPa, 0.0992MPa and 0.2480MPa respectively. The results of the sieving index and stability improvement rate of each sample determined in this way are shown in Table 3.

[0044] Table 3 Example 2 each sample residue index and stability improvement rate result table

[0045]

[0046]

[0047] It can be seen from Table 3 that the stability improvement rates of the grade five steel slags after screening and classification are 615.07%, 529.94%, 423.15%, 342.56% and 316.45% in ascending order of labels.

Embodiment 3

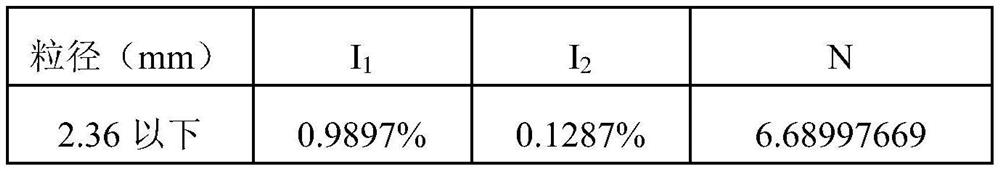

[0049] The steps of embodiment 3 are basically the same as those of embodiment 1, except that the carbonization intensity of the steel slag of the experimental group I to V is respectively set to 9MPa h, 18.5MPa h, 36MPa h, 78MPa h, 196MPa h h, CO in the corresponding carbonization box or carbonization kettle 2 The partial pressure strengths are 0.0179MPa, 0.0357MPa, 0.0714MPa, 0.1548MPa and 0.3889MPa, respectively. The results of the sieve index and stability improvement rate of each sample thus determined are shown in Table 4.

[0050] Table 4 embodiment 3 each sample residue index and stability improvement rate result table

[0051] Particle size (mm) I 1

[0052] It can be seen from Table 4 that the stability improvement rates of the grade five steel slag after screening and grading are 682.93%, 589.29%, 477.20%, 362.75% and 346.84% in ascending order of labels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com