A process for producing fulvic acid fertilizer and high-strength corrugated paper with cotton straw as raw material

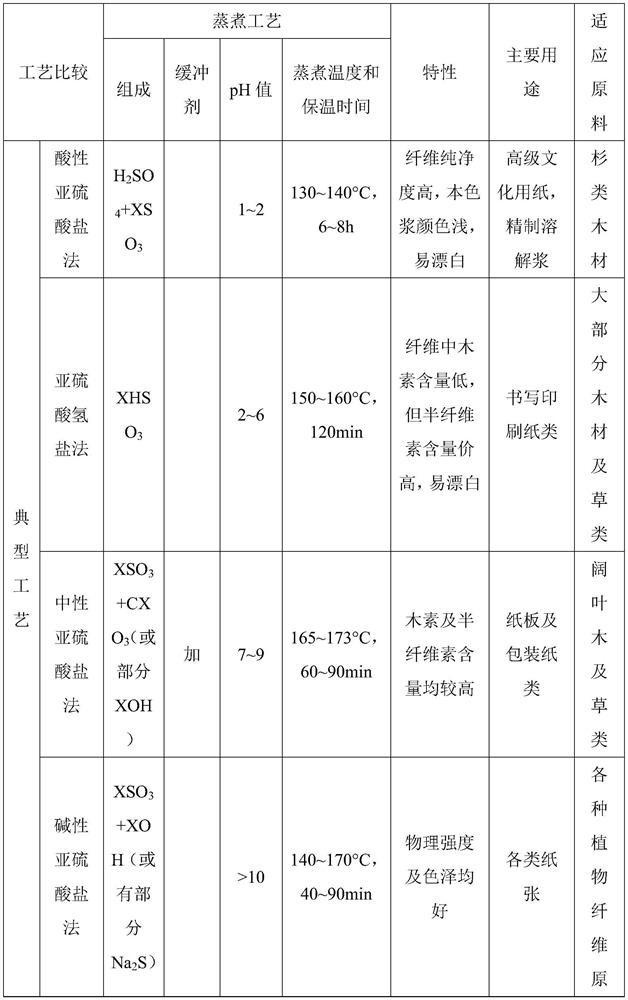

A technology of fulvic acid and cotton stalks, applied in textiles and papermaking, fiber raw material processing, papermaking, etc., can solve the problems of dark pulp color, immature, complete and effective cotton stalk raw material resources comprehensive utilization technology, neglect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

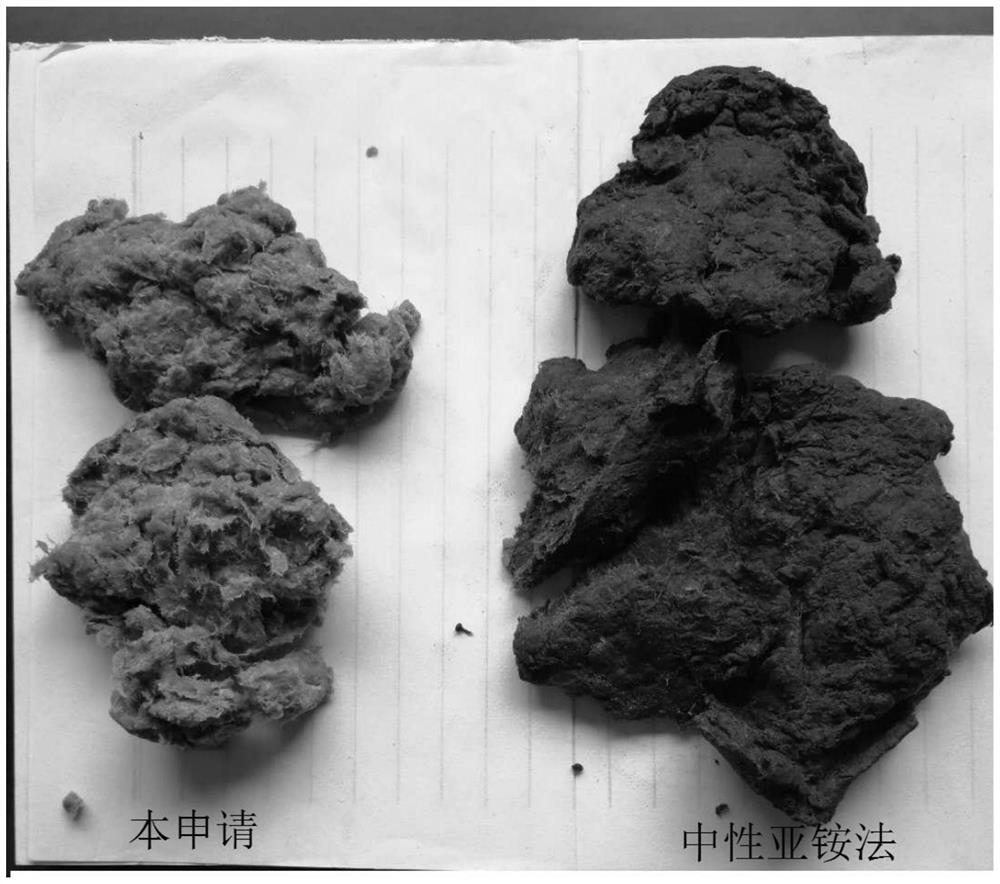

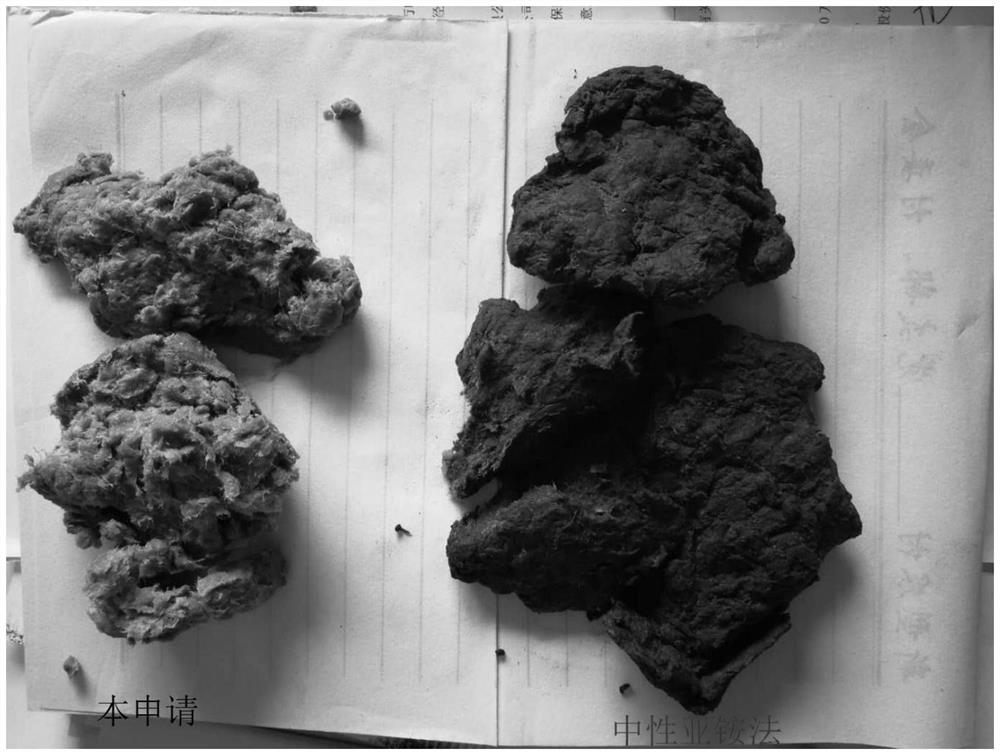

Image

Examples

Embodiment 1

[0069] (1) The process flow is: crushing the whole cotton straw, dedusting, cooking, refining, and extracting the black liquor. , dedusting, cooking, extracting black liquor, high-consistency refining, and extracting black liquor. The follow-up process is divided into two steps, one is pulp washing, high-consistency Collect and process black liquor, and then produce liquid form of fulvic acid fertilizer according to needs, or produce solid form of fulvic acid fertilizer through concentration and granulation.

[0070] (2) The raw material of cotton stalks taken from Alar City, First Division of Xinjiang Corps, crushed to 3-5mm, including the main neck, twigs, skins and residual boll shells of cotton stalks, including cotton stalk skins, cotton stalks Cotton core, including cotton stalk core pith and residual cotton, weigh 1000g dry.

[0071] (3) The cooking process conditions are: heating to 120°C at room temperature, releasing steam for 20 minutes, continuing to heat to a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com