Preparation method and application of brown algae polyphenol

A technology of brown algae polyphenols and brown algae, which is applied in the field of preparation of brown algae polyphenols, can solve the problems of low extraction efficiency and low utilization rate of raw materials, and achieve the effects of high extraction efficiency, high utilization rate of raw materials, and remarkable therapeutic and preventive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing brown algae polyphenols, comprising the steps of:

[0019] Freeze the brown algae at a temperature of -30 to -40°C, take it out after freezing for 15 to 20 days, and thaw at room temperature until the temperature of the brown algae reaches 0 to 1°C;

[0020] Put the thawed brown algae in a centrifuge to remove water;

[0021] adding an organic solvent to the brown algae after water removal, extracting in the dark for 1 to 12 hours, and then suction filtering to obtain an extract;

[0022] Concentrate the extract at 30-40°C until the amount of precipitate in the solution no longer increases, and filter to remove the precipitate to obtain the first filtrate;

[0023] Crystallize the first filtrate at a low temperature of 5-20°C for 5-10 hours, and filter to obtain the second filtrate;

[0024] adding a fat-soluble solvent to the second filtrate, performing liquid-liquid extraction, and retaining a fat-soluble solvent layer; ...

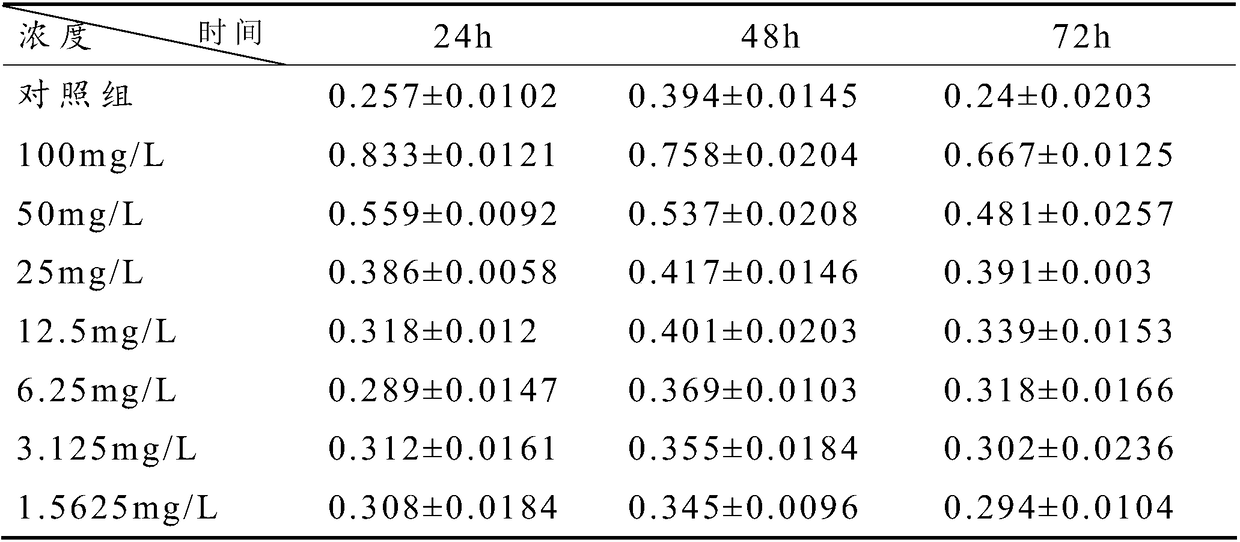

Embodiment 1

[0036] Freeze the fresh wakame at -40°C, take it out after 15 days of freezing, and thaw it in air at room temperature until the center temperature of the wakame reaches 1°C to complete the freeze-thaw process; put the wakame into a centrifuge , centrifuged at 2000rpm for 10min to remove moisture; through repeated freeze-thaw and centrifugation for 3 times, the water content of Undaria pinnatifida was controlled to be 60%. Weigh 100g of Undaria pinnatifida and put it into a 1000mL conical beaker, add 300mL of 85% (V / V) ethanol aqueous solution, seal the mouth of the conical beaker with plastic wrap, leaching in the dark for 1 hour, and suction filtration. Continue to add 85% (v / v) ethanol aqueous solution 300mL again to the above-mentioned leaching treatment of wakame, seal the mouth of the triangular beaker with a safety film, leaching in the dark for 1 hour, and suction filtration. Repeatedly leached in the dark until the extract was colorless, and the filtrates were combine...

Embodiment 2

[0039] Freeze the fresh hijiki at -30°C, take it out after 20 days of freezing, and thaw it in the air at room temperature until the center temperature of the hijiki reaches 1°C. put into a centrifuge, and centrifuge at a speed of 1200rpm for 20min to remove water; through repeated freezing and thawing and centrifugation twice, the moisture content of Hijiki is controlled to be 60%. Weigh 100g of Hijiki and put it into a 1000mL conical beaker, add 300mL of 80% (V / V) ethanol aqueous solution, seal the mouth of the conical beaker with plastic wrap, extract in the dark for 1 hour, and filter with suction. Continue to add 300 mL of 80% (v / v) ethanol aqueous solution to the above-mentioned leaching treatment of Hijiki again, seal the mouth of the triangular beaker with a safety film, leaching in the dark for 1 hour, and suction filtration. Repeatedly leached in the dark until the extract was colorless, and the filtrates were combined. Concentrate the filtrate at 40°C. During conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com