Novel stirring process for positive electrode slurry of lithium ion battery

A technology for lithium ion battery and cathode slurry, which is applied in the directions of dissolution, chemical instruments and methods, mixing methods, etc., can solve the problems of accelerated equipment loss, shortened service life, uneven mixing of slurry, etc., so as to reduce loss and prolong use. Longevity and effect of improving dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

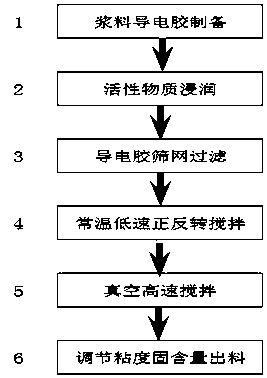

[0018] In the embodiment of the present invention, a novel lithium-ion battery positive electrode slurry stirring process, the specific steps are as follows:

[0019] (1) Preparation of conductive glue: use a disperser to pre-prepare the binder, solvent, and conductive agent powder into conductive glue according to a certain ratio;

[0020] (2) Active material infiltration: Mix the active material and NMP in a mixer with double revolution and rotation shafts, rotate clockwise at low speed for 10 minutes at a speed of 15 rpm, and then rotate counterclockwise for 10 minutes at a speed of 15 rpm to fully disperse the conductive agent in the active material. in the substance;

[0021] (3) Forward and reverse stirring at low speed at room temperature: sieve the prepared conductive glue with three layers of 600-mesh screens, add 1 / 2 of the sieved conductive glue into the mixer, rotate at a low speed of 300rpm, and rotate The rotation speed is 15rpm, the time is 10min, and finally t...

Embodiment 2

[0025] In the embodiment of the present invention, a novel lithium-ion battery positive electrode slurry stirring process, the specific steps are as follows:

[0026] (1) Preparation of conductive glue: use a disperser to pre-prepare the binder, solvent, and conductive agent powder into conductive glue according to a certain ratio;

[0027] (2) Active material infiltration: Mix the active material and NMP in a mixer with double revolution and rotation shafts, rotate clockwise at a low speed for 20 minutes at a speed of 20 rpm, and then rotate counterclockwise for 20 minutes at a speed of 20 rpm to fully disperse the conductive agent in the active material. in the substance;

[0028] (3) Forward and reverse stirring at low speed at room temperature: sieve the prepared conductive glue with three layers of 600-mesh screens, add 1 / 2 of the sieved conductive glue into the mixer, rotate at a low speed of 400rpm, and rotate The rotation speed is 20rpm, the time is 20min, and finally...

Embodiment 3

[0032] In the embodiment of the present invention, a novel lithium-ion battery positive electrode slurry stirring process, the specific steps are as follows:

[0033] (1) Preparation of conductive glue: use a disperser to pre-prepare the binder, solvent, and conductive agent powder into conductive glue according to a certain ratio;

[0034] (2) Active material infiltration: Mix the active material and NMP in a mixer with double revolution and rotation shafts, rotate clockwise at low speed for 30 minutes at a speed of 25 rpm, and then rotate counterclockwise for 30 minutes at a speed of 25 rpm to fully disperse the conductive agent in the active material. in the substance;

[0035] (3) Normal temperature and low speed forward and reverse stirring: sieve the prepared conductive glue with three layers of 600-mesh screens, add 1 / 2 of the sieved conductive glue into the mixer, rotate at a low speed of 500rpm, and rotate The rotation speed is 25rpm, the time is 30min, and finally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com