Phosphate-containing pitch anti-stripping agent and use method thereof

A technology of anti-stripping agent and phosphate salt, which is applied in the field of asphalt anti-stripping agent, can solve the problems of not obvious water damage, cumbersome use methods, environmental pollution, etc., and achieve excellent performance, long-term aging resistance, and reduce water damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An asphalt antistripping agent containing phosphate ester salt is composed of sodium lauryl phosphate and octadecyl trimethyl ammonium chloride, and the weight ratio of the two components is 2:3.

[0017] Preparation of sodium dodecyl phosphate: add lauryl alcohol into a three-necked flask equipped with a stirrer, heat to 65°C, add phosphorus pentoxide, heat to 90°C, stir well, react for 2 hours, add hydroxide Sodium is neutralized to obtain sodium dodecyl phosphate, and the mass ratio of lauryl alcohol, phosphorus pentoxide and sodium hydroxide is 1:1:1.

[0018] Octadecyltrimethylammonium chloride was purchased from Anhui Jinao Chemical Co., Ltd.

[0019] The method of using the asphalt anti-stripping agent containing phosphate ester salt: heating the asphalt of AH-70 to 130°C,

[0020] Fully mix with the asphalt anti-stripping agent containing phosphate ester salt, the weight of the anti-stripping agent accounts for 0.2% of the hot asphalt weight.

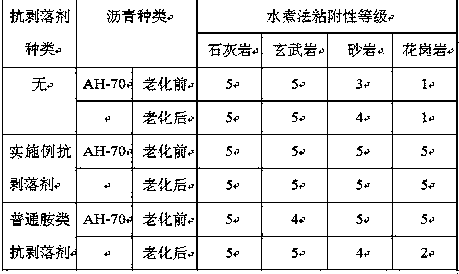

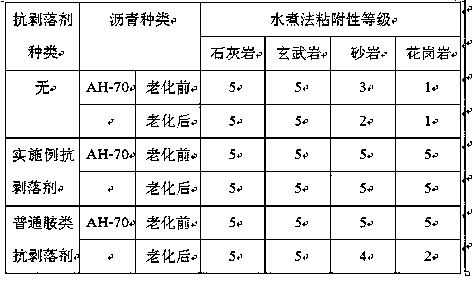

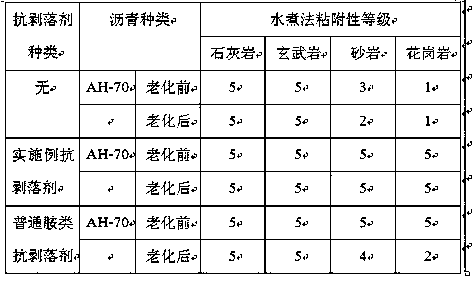

[0021] Accordin...

Embodiment 2

[0023] The composition of the asphalt antistripping agent containing phosphate ester salt is sodium lauryl phosphate and octadecyltrimethylammonium chloride, and the weight ratio of the two components is 1:1.

[0024] Preparation of sodium dodecyl phosphate: add lauryl alcohol into a three-necked flask equipped with a stirrer, heat to 65°C, add phosphorus pentoxide, heat to 90°C, stir well, react for 2 hours, add hydroxide Sodium is neutralized to obtain sodium dodecyl phosphate, and the mass ratio of lauryl alcohol, phosphorus pentoxide and sodium hydroxide is 1:1:1.

[0025] Octadecyltrimethylammonium chloride was purchased from Anhui Jinao Chemical Co., Ltd.

[0026] The method of using the asphalt anti-stripping agent: heat the asphalt of AH-70 to 135°C,

[0027] Fully mix with the asphalt anti-stripping agent containing phosphate ester salt, the weight of the anti-stripping agent accounts for 0.3% of the hot asphalt weight.

[0028] According to the JTGE-2011 test proce...

Embodiment 3

[0030] The composition of the asphalt antistripping agent containing phosphate ester salt is sodium lauryl phosphate and octadecyltrimethylammonium chloride, and the weight ratio of the two components is 5:6.

[0031] Preparation of sodium dodecyl phosphate: add lauryl alcohol into a three-necked flask equipped with a stirrer, heat to 65°C, add phosphorus pentoxide, heat to 90°C, stir well, react for 2 hours, add hydroxide Sodium is neutralized to obtain sodium dodecyl phosphate, and the mass ratio of lauryl alcohol, phosphorus pentoxide and sodium hydroxide is 1:1:1.

[0032] Octadecyltrimethylammonium chloride was purchased from Anhui Jinao Chemical Co., Ltd.

[0033] The method of using the asphalt anti-stripping agent: heat the asphalt of AH-70 to 140°C,

[0034] Fully mix with the asphalt anti-stripping agent containing phosphate ester salt, the weight of the anti-stripping agent accounts for 0.35% of the hot asphalt weight.

[0035] According to the JTGE-2011 test pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com