Patents

Literature

84 results about "Didodecyl phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricant and functional fluid additive package, and lubricants and functional fluids containing same

InactiveUS20120088704A1Stable storageLow lubricantOther chemical processesAdditivesPolyolefinAntioxidant

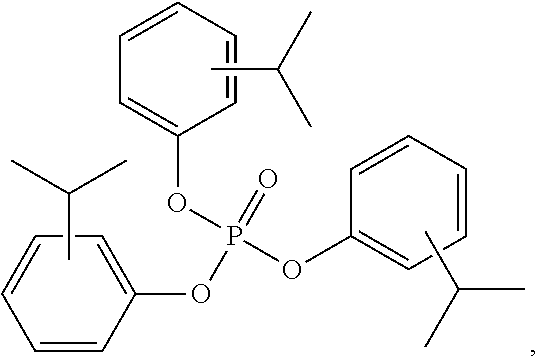

The present invention is a lubricant or functional fluid additive for a polyolefin oil blend, comprising a mixture of: (a) an anti-wear component consisting essentially of 95% isopropylated triarylphosphate and 5% dodecyl phosphate, the dodecyl phosphate being only partially esterified, the anti-wear component present in the polyolefin oil blend in a range of from about 0.75 percent to about 2.00 percent by weight; (b) an antioxidant component selected from the group consisting of alkylated phenyl-alpha-naphthylamine, phenyl-alpha-naphthylamine and mixtures thereof, and present in the polyolefin oil blend in a range of from about 0.75 percent to about 2.00 percent by weight; (c) an anti-rust component comprising an alkylated succinic acid ester anti-rust agent, and present in the polyolefin oil blend in a range of from about 0.050 percent to about 0.125 percent by weight; and (d) a metal deactivator component comprising a tolytriazole derivative, and present in the polyolefin oil blend in a range of from about 0.050 percent to about 0.125 percent by weight.

Owner:MATERIALS ENG & TECHN SUPPORT SERVICES CORP METABS CORP

Flame retardant viscose fiber and preparation method thereof

ActiveCN102561031AImprove flame retardant performanceImprove water retentionFibre treatmentPolymer scienceBetaine

The invention discloses a flame retardant viscose fiber and a preparation method thereof. The preparation method of the flame retardant viscose fiber comprises the following steps of adding a flame retardant emulsion into a viscose solution, uniformly mixing, carrying out filtration, and carrying out molding by a conventional wet spinning technology to obtain the flame retardant viscose fiber. A mass ratio of the flame retardant emulsion to the viscose solution is in a range of (1: 100) to (5: 100). The flame retardant emulsion comprises: by weight, 20 to 30 parts of N,N'-di(diphenoxythiophosphoryl)dithioethyldiamide, 5 to 10 parts of tris(2-chloropropyl) phosphate, 10 to 15 parts of cocoamidopropyl betaine, 5 to 10 parts of potassium dodecyl phosphate, 20 to 25 parts of Tween-60, and 500to 800 parts of water. The flame retardant viscose fiber has good flame retardant effects and a high water-retaining capacity.

Owner:GUANGZHOU CANUDILO FASHION & ACCESSORIES CO LTD

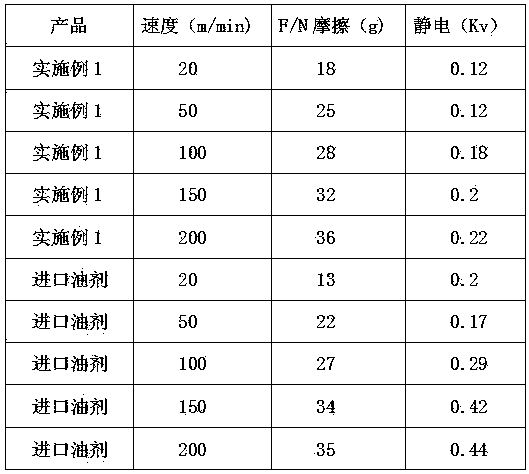

Nylon oiling agent

The invention discloses a nylon oiling agent, which is composed of mineral oil, hexadecyl potassium phosphate, dodecyl phosphate diethanol ammonium salt, castor oil polyoxyethylene (40) ester and sorbitan stearate. The nylon oiling agent has the advantages of reasonable formula, good use effect and low production cost.

Owner:张兴良

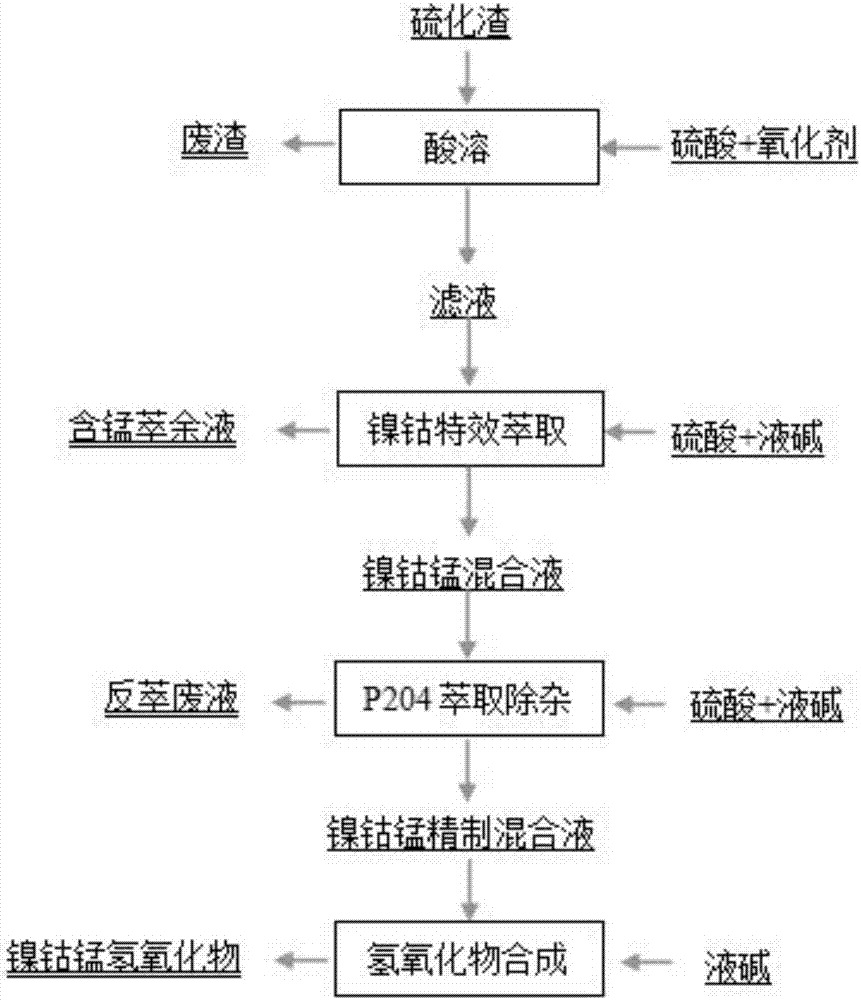

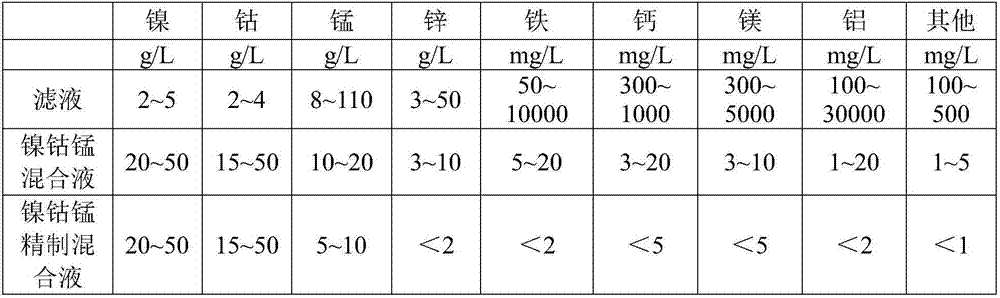

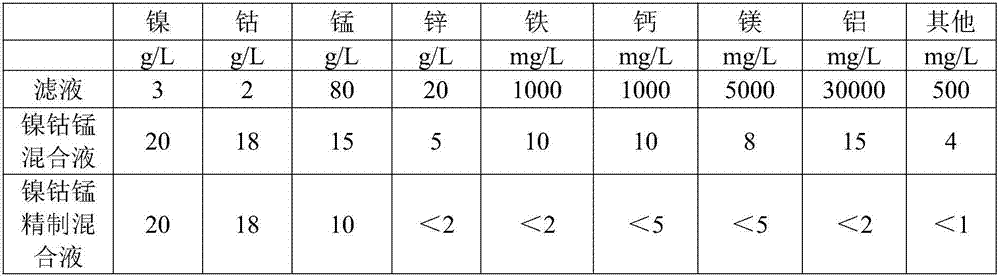

Method for recovering and purifying nickel cobalt from manganese-containing waste material

ActiveCN106904667AReduce security risksLow costNickel compounds preparationManganese sulfatesManganeseSulfide

The invention relates to a method for recovering and purifying nickel cobalt from a manganese-containing waste material. The method comprises the following steps: the manganese-containing waste sulfide residues is subjected to slurrying, an acid solution and oxidant are added to the sulfide residues for being dissolved, and the acid-soluble waste residue and a filtrate are obtained; the filtrate is subjected to saponification by liquid caustic soda and then extraction by a nickel cobalt specific extractant to obtain a raffinate containing manganese; a nickel and cobalt-organic phase is extracted by dilute sulfuric acid to obtain a nickel cobalt manganese mixture; the nickel cobalt manganese mixture is subjected to impurities extraction with a dodecyl alkyl phosphate extraction agent after saponification and then is subjected to purification to obtain a nickel cobalt manganese refining mixture; according to the stoichiometric ratio of nickel cobalt manganese metals, the corresponding sulfate is supplemented, and a precursor nickel cobalt manganese hydroxide of lithium cobalt nickel manganese is synthesized by adding the liquid caustic soda. The method has the advantages of effective utilization of waste resources, low cost, good impurity removing effect, and small environmental risk.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

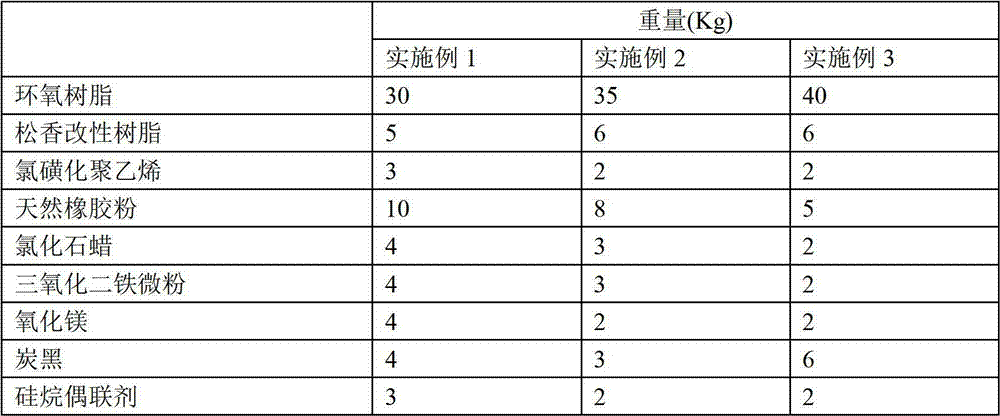

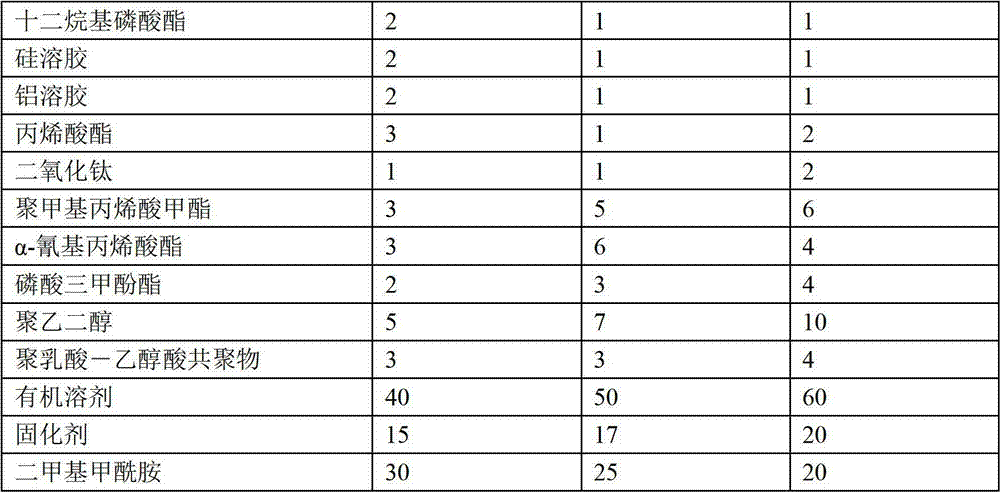

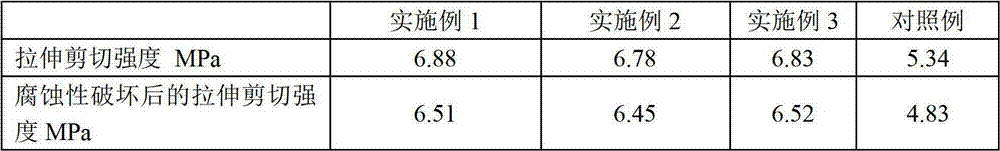

Epoxy resin adhesive for bonding fluororubber and metal

InactiveCN102876242AHigh bonding strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePhosphatePolyethylene glycol

The invention provides an epoxy resin adhesive for bonding fluororubber and metal. The adhesive comprises component A and component B. The component A comprises the following materials by weight: 30-40 parts of epoxy resin, 5-6 parts of rosin-modified resin, 2-3 parts of chlorosulfonated polyethylene, 5-10 parts of natural rubber powder, 2-4 parts of chlorinated paraffin, 2-4 parts of ferric oxide micropowder, 2-4 parts of magnesia, 3-6 parts of carbon black, 2-3 parts of a silane coupling agent, 1-2 parts of dodecyl phosphate, 1-2 parts of silica sol, 1-2 parts of alumina sol, 1-3 parts of acrylate, 1-2 parts of titanium dioxide, 3-6 parts of polymethyl methacrylate, 3-6 parts of alpha-cyanoacrylate, 2-4 parts of tricresyl phosphate, 5-10 parts of polyethylene glycol, 3-4 parts of poly(lactic acid-co-glycolic acid), and 40-60 parts of organic solvent. The component B comprises the following materials by weight: 15-20 parts of a curing agent, and 20-30 parts of dimethyl formamide.

Owner:上海拜高高分子材料有限公司

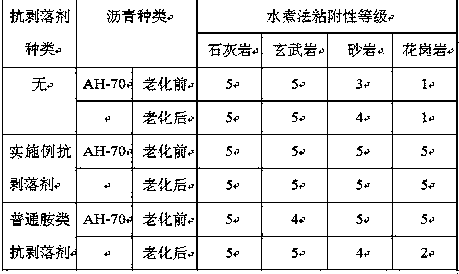

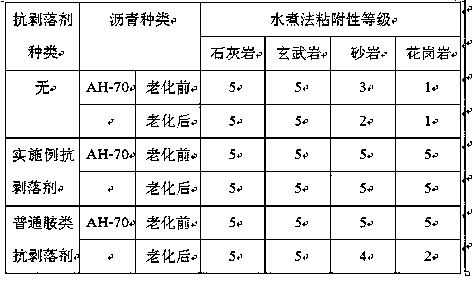

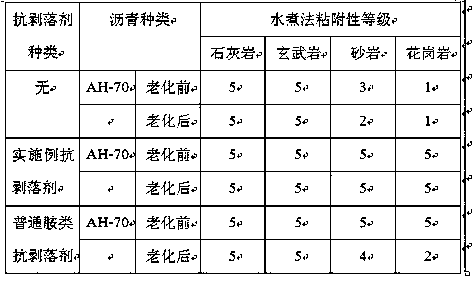

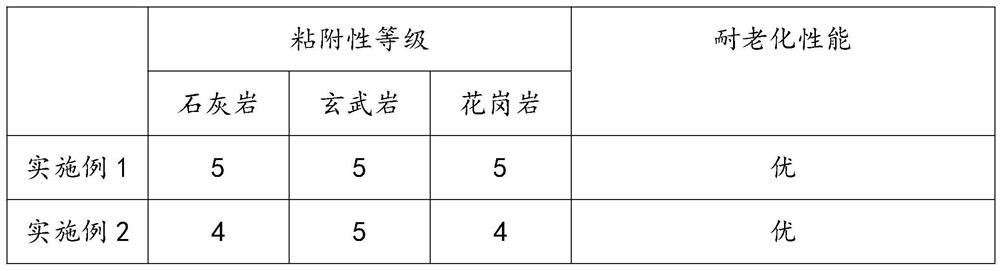

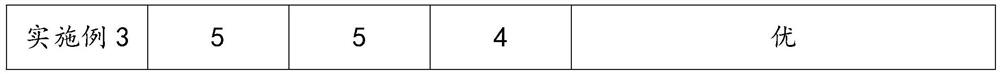

A synthesis process of a monododecyl phosphate asphalt anti-stripping agent

InactiveCN104693234AHigh activityImprove adaptabilityGroup 5/15 element organic compoundsBuilding insulationsPhosphateReaction temperature

The invention synthesizes a dodecylphosphate mixture from phosphorus pentoxide and lauryl alcohol by an esterification reaction. By adopting monododecyl phosphate as a target product, influences of each reaction parameter on the reaction yield are researched, and the optimum synthesis conditions are determined as follows: the reaction time is 4 h, the mole ratio of the lauryl alcohol to the phosphorus pentoxide is 2.1, the reaction temperature is 85 DEG C, and the mole ratio of water to the phosphorus pentoxide is 0.8. The yield of the monododecyl phosphate can be 80% under the optimum reaction conditions. Anti-stripping performance of the monododecyl phosphate is tested by utilization of a water boiling method, and results show that: when an anti-stripping agent is not added, adhesion of asphalt and granite building stone is of the second grade; when an anti-stripping agent is added, adhesion of asphalt and granite building stone is of the fourth grade; and the monododecyl phosphate synthesized has good anti-stripping performance.

Owner:QINGDAO HUICHENG PETROCHEM TECH

Pearl anti-ultraviolet fiber and preparation method thereof

InactiveCN103374764AImproves UV protectionImprove spinnabilityArtificial filaments from viscoseArtifical filament manufactureEmulsionPhosphate

The invention discloses a pearl anti-ultraviolet fiber and a preparation method thereof. The pearl anti-ultraviolet fiber is prepared through the following steps: adding an anti-ultraviolet functional emulsion into a viscose solution, uniformly mixing, filtering, and forming according to a conventional wet spinning and jetting process, thus obtaining the pearl anti-ultraviolet fiber, wherein the mass ratio of the anti-ultraviolet functional emulsion to the viscose solution is (2:100)-(5:100); and the anti-ultraviolet functional emulsion is composed of the following components in parts by weight: 20-30 parts of pearl powder, 1-3 parts of isononyl isononanoate, 0.2-0.4 part of anti-ultraviolet agent, 10-15 parts of pendecamaine, 5-10 parts of potassium dodecyl phosphate, 20-25 parts of Tween-60 and 100-200 parts of water. The pearl anti-ultraviolet fiber disclosed by the invention is as glossy as silk in appearance and has remarkable anti-ultraviolet effect.

Owner:江阴市向阳特种化纤有限公司

Environment-friendly alcohol-free fountain solution for offset printing and preparing method thereof

InactiveCN104960354AMeet high viscosity requirementsControl and prevent pollutionPrinting pre-treatmentEthylenediamineBetaine

The invention discloses an environment-friendly alcohol-free fountain solution for offset printing and a preparing method thereof. The solution is prepared from, by weight, 4-7 parts of lauryl polyoxyethylene, 6-8 parts of coconut diethanolamide, 3-5 parts of petroleum sodium sulfonate, 4-6 parts of potassium pyrophosphate, 10-14 parts of trisodium citrate, 8-10 parts of Arabic gum, 4-5 parts of dodecyl polyglucoside, 2-4 parts of hydroxyethyl ethylenediamine, 7 parts of dimethyl dodecyl amine oxide, 2-3 parts of di-o-tolyl-thiourea, 1-2 parts of sodium carboxymethylcellulose, 0.6-0.8 part of methylisothiazolinone, 4-5 parts of Turkey red oil, 0.8-1.2 parts of ethylene diamine tetraacetic acid tetrasodium, 0.6-0.8 part of tea saponin, 3-5 parts of dipropylene glycol methyl ether, 3-4 parts of dodecyl betaine type phosphate, 2-3 parts of sodium hexametaphosphate, and 120-140 parts of deionized water. According to the fountain solution, alcohol of any kinds is not added, no volatile harmful substance is contained, environment friendliness is realized completely, no harm can be done to the human body, a quite strong microorganism killing effect can be realized, microbial pollution of the fountain solution can be controlled and prevented, metal parts can be prevented from being corroded, and a printing plate and a printing machine are prevented from being damaged by early water.

Owner:李子健

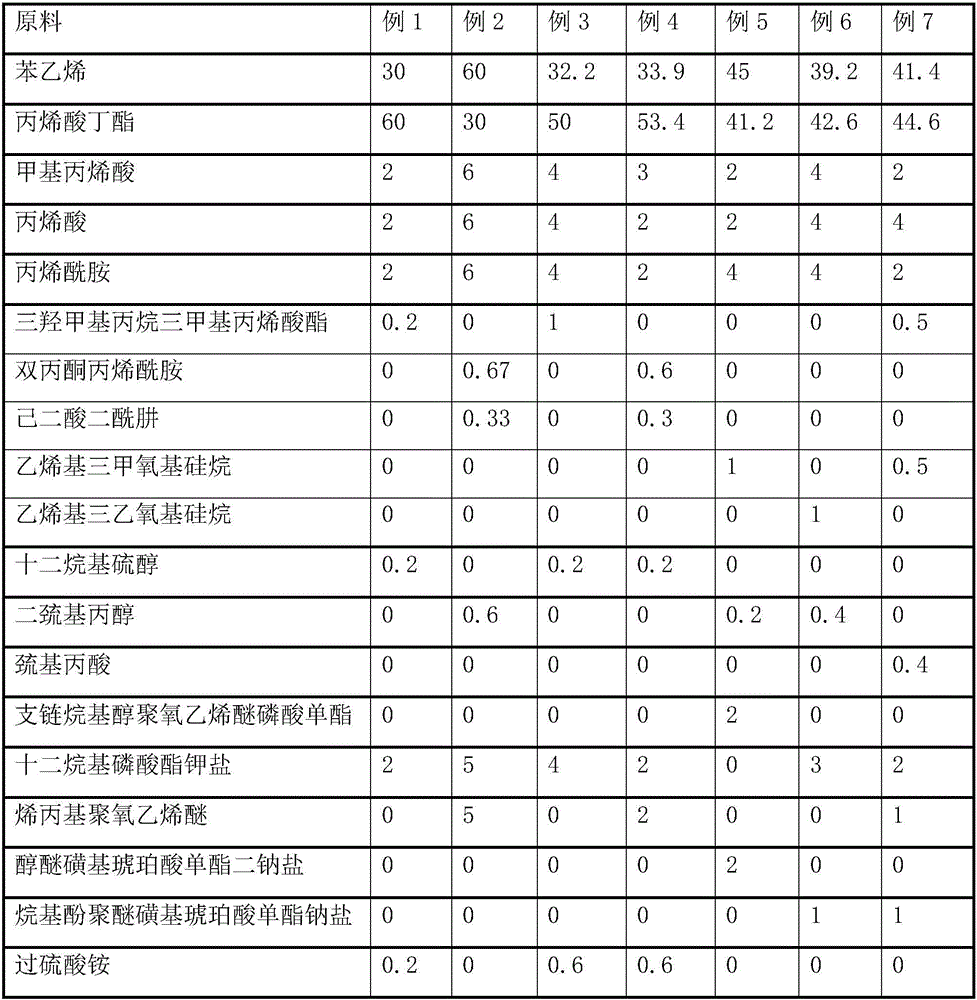

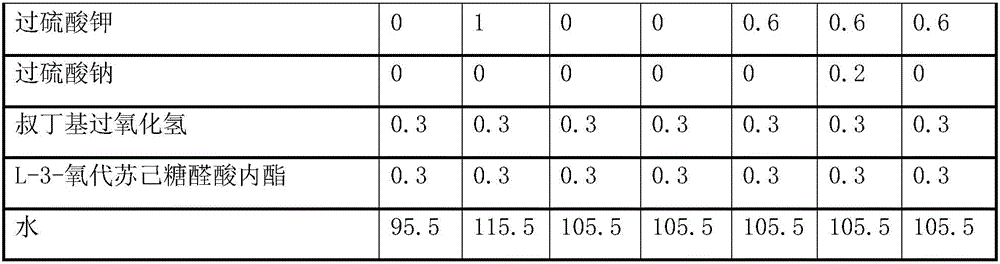

Styrene-acrylic emulsion for repainting primer and preparation method of styrene-acrylic emulsion

ActiveCN106632821ASolve the problem that it cannot be directly used to powder the wallImprove permeabilityCoatingsCross-linkPhosphate

The invention discloses styrene-acrylic emulsion for repainting a primer and a preparation method of the styrene-acrylic emulsion, and belongs to the field of coating chemistry. The styrene-acrylic emulsion for repainting the primer is prepared from the following raw materials in parts by weight: 30 to 60 parts of styrene, 30 to 60 parts of butyl acylate, 2 to 6 parts of methacrylic acid, 2 to 6 parts of acrylic acid, 2 to 6 parts of acrylamide, 0.2 to 1 part of a cross-linking monomer, 2 to 10 parts of an emulsifier, 0.2 to 0.6 part of a chain transfer agent, 0.2 to 1.0 part of persulfate, 0.3 part of an oxidant, 0.3 part of a reducing agent and 95.5 to 115.5 parts of water, wherein the emulsifier is at least one of branched alkyl alcohol polyoxylethylene ether phosphate mono-ester, potassium dodecyl phosphate, allyl polyethenoxy ether, disodium polyoxyethylene sulfosuccinate and sodium alkylphenol ether sulfosuccinate. The styrene-acrylic emulsion for repainting the primer can be directly used for repainting of a painted wall.

Owner:成都巴德富科技有限公司

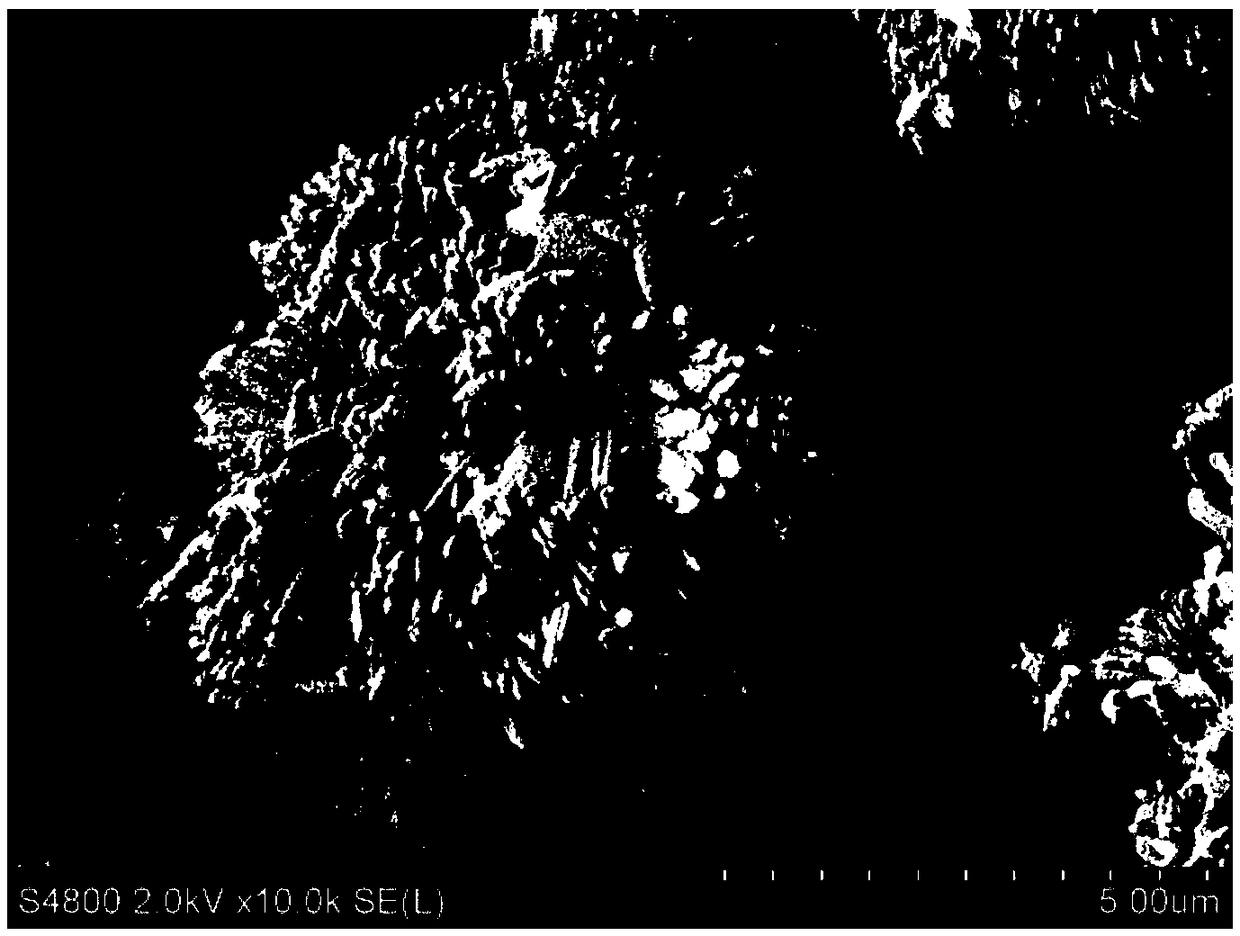

Preparation method of modified basalt fiber-whisker reinforced silane cross-linking wear-resistant master batches

InactiveCN108976689AIncreased surface carboxyl contentImprove surface roughnessWater bathsCross-link

The invention discloses a preparation method of modified basalt fiber-whisker reinforced silane cross-linking wear-resistant master batches. The preparing the method comprises the following steps: uniformly mixing grafted master batches with basalt fiber after surface modification treatment, organic modified hydrotalcite and alpha-semi-hydrated gypsum whiskers after the surface modification treatment, and carrying out cross-linking reaction in a water bath, thus preparing the silane cross-linking wear-resistance master batches. According to the preparation method disclosed by the invention, hydrotalcite is used as filler, potassium dodecyl phosphate is adopted as an organic negative ion modifier, and magnesium-aluminum hydrotalcite is organic modified through an interlayer anion exchangemethod by utilizing the characteristic of replaceability of the interlayer anion of the hydrotalcite, so that the organic hydrotalcite is obtained; the adhesion between the hydrotalcite and a polyolefin matrix is enhanced; starch and nano calcium carbonate are used for filling the modified polyether resin, reinforcing and toughening functions are obtained, and the fluidity and the tensile propertyof the modified polyethylene can be enhanced.

Owner:界首市鑫一龙机械设备购销有限公司

Prepartion method of calcium sulphate dihydrate crystal whisker

InactiveCN101586255APolycrystalline material growthFrom normal temperature solutionsSulphate IonWhiskers

The invention relates to a method for preparing calcium sulphate dihydrate crystal whisker, adding dodecyl phosphate potassium and nonylphenol polyethoxylate (TX10), and adding dilute sulphuric acid in agitation, standing the reaction solution for four to six hours, filtering, the filtering material is calcium sulphate dihydrate crystal whisker. Reacting filtrate with limestone to regenerate calcium chloride solution, adding dilute sulphuric acid sequentially to generate calcium sulphate dihydrate crystal whisker once more. The method is using limestone and dilute sulphate acid as raw materials to prepare calcium sulphate dihydrate crystal whisker, possessing characteristics of simple process and low cost, which is suitable for industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for improving corrosion resistance of cathode aluminum plate for zinc electrolysis

ActiveCN101781780AImprove surface qualityImprove corrosion resistancePhotography auxillary processesProcess efficiency improvementAlkaneElectrolysis

The invention discloses a method for improving the corrosion resistance of a cathode aluminum plate for zinc electrolysis, which comprises the steps of rolling with rolling oil of particular composition formula and treatment after rolling the aluminum plate. The composition formula of the rolling oil consists of basic oil and additives, wherein the basic oil is of lubricant with the boiling range of 225.7 to 243.3 DEG C, flash point of the lubricant is 95 DEG C, the viscosity (at the temperature of 40 DEG C) is 1.9 to 2.0 mm2 / s, the additives are of methyl alkanes and dodecyl phosphate, the composition ratio of the basic oil, the methyl alkanes and dodecyl phosphate is 100: 3: 1 to 100: 8:1, the aluminum plate after being rolled is processed by sodium silicate solution with the concentration of 0.5 to 2 percent at the temperature of 70 to 0 DEG C for 2 to 10 minutes, and the service life can be improved by more than three times.

Owner:CENT SOUTH UNIV +1

Biodegradable spandex for paper diaper, and preparation method thereof

ActiveCN104630929AFast biodegradationImprove adhesionMonocomponent synthetic polymer artificial filamentArtifical filament manufactureAntioxidantPhosphate

The invention relates to a biodegradable spandex for paper diaper, which comprises biodegradation promotion composition and spandex for paper diaper, wherein the biodegradation promotion composition includes potassium dodecyl phosphate, sodium lauroyl glutamate and UV-320. The preparation method of the biodegradable spandex for paper diaper comprises the following steps: 1) enabling oligomer diol to react with diisocyanate to generate prepolymer; 2) performing chain propagation reaction to the prepolymer through amine chain extender, to obtain polymer stock solution; 3) adding the biodegradation promotion composition to the polymer stock solution, and adding an antioxidant, a delustering agent and a lubricant, fully stirring, to obtain spinning stoack solution; and 4) performing dry-process spinning to the spinning stock solution to prepare the biodegradable spandex for paper diaper. The biodegradable spandex for paper diaper has high biodegradation speed, excellent adhesion effect with base materials, and smooth unwinding property.

Owner:ZHEJIANG HUAFENG SPANDEX

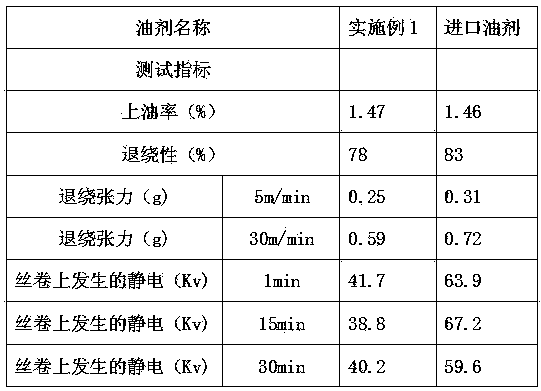

Dry-process polyimide spinning oil

ActiveCN104213414ASolve the problem of static electricitySolve the problem of unwindingFibre typesFiber bundlePhosphate

The invention relates to a dry-process polyimide spinning oil which is prepared from the following raw materials in parts by weight: 30 to 60 parts of simethicone, 10 to 30 parts of refined mineral oil, 3 to 9 parts of sorbitan tristearate polyoxyethylene ether, 5 to 10 parts of dodecyl phosphate diethanolamine salt, 8 to 14 parts of hexadecyl potassium phosphate and 10 to 20 parts of fatty alcohol-polyoxyethylene ether. The dry-process polyimide spinning oil prepared from the simethicone, the refined mineral oil, sorbitan tristearate polyoxyethylene ether, the dodecyl phosphate diethanolamine salt, hexadecyl potassium phosphate and fatty alcohol-polyoxyethylene ether is reasonable in formula, good in application effect and low in production cost; and in addition, the problems that fibers cannot be easily unwound and fiber bundles cannot be well gathered due to large static electricity among the fibers and the like are solved well.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD

Method for preparing large grain anhydrous sodium sulfate

InactiveCN101007640AExtended induction periodEnhanced interface energyAlkali metal sulfite/sulfate dehydrationPhosphatePolyethylene glycol

The invention discloses a making method of large-particle anhydrous sodium sulfate, which comprises the following steps: adding 0.01%-10% surface activator with one or more of dodecyl phosphate ester, dodecyl sodium benzosulfonate, dodecyl dimethyl amine oxide, phenylethene or carbowax; adding water under 60-260 deg.c; keeping the constant density of solution to react 1.5-3.0h; stopping heating; filtering; drying; obtaining 80% product over 40 order.

Owner:HEBEI UNIVERSITY

Method for improving corrosion resistance of cathode aluminum plate for zinc electrolysis

ActiveCN101781780BImprove surface qualityImprove corrosion resistancePhotography auxillary processesProcess efficiency improvementAlkaneElectrolysis

The invention discloses a method for improving the corrosion resistance of a cathode aluminum plate for zinc electrolysis, which comprises the steps of rolling with rolling oil of particular composition formula and treatment after rolling the aluminum plate. The composition formula of the rolling oil consists of basic oil and additives, wherein the basic oil is of lubricant with the boiling rangeof 225.7 to 243.3 DEG C, flash point of the lubricant is 95 DEG C, the viscosity (at the temperature of 40 DEG C) is 1.9 to 2.0 mm2 / s, the additives are of methyl alkanes and dodecyl phosphate, the composition ratio of the basic oil, the methyl alkanes and dodecyl phosphate is 100: 3: 1 to 100: 8:1, the aluminum plate after being rolled is processed by sodium silicate solution with the concentration of 0.5 to 2 percent at the temperature of 70 to 0 DEG C for 2 to 10 minutes, and the service life can be improved by more than three times.

Owner:CENT SOUTH UNIV +1

Phosphate-containing pitch anti-stripping agent and use method thereof

The invention discloses an additive of asphalt material for pavement engineering, in particular to a phosphate-containing asphalt anti-stripping agent and a use method thereof. The phosphate-containing asphalt anti-stripping agent is composed of sodium dodecyl phosphate and octadecyl trimethyl ammonium chloride, and the use method comprises the step of uniformly mixing the anti-stripping agent with hot asphalt, wherein the weight of the anti-stripping agent accounts for 0.2% to 0.4% of that of the hot asphalt. When the anti-stripping agent is used for asphalt modification, the long-term agingresistance of the anti-stripping agent is superior to that of traditional amine anti-stripping agents.

Owner:江苏金阳新材料科技有限公司

Plastic additive taking talcum powder as matrix and preparation method of plastic additive

InactiveCN108623973AImprove interface compatibilityWeaken electrostatic interactionsALUMINUM PHOSPHATERaw material

The invention discloses a plastic additive taking talcum powder as a matrix and a preparation method of the plastic additive, and belongs to the technical field of a plastic additive. The preparationmethod comprises the following steps: pretreating aluminium magnesium hydrotalcite by using citric acid, modifying the aluminium magnesium hydrotalcite by using potassium lauryl phosphate, carrying out a reaction between 2,2'-methylene-bi(4,6-ditert butyl benzene)phosphoryl chloride and acetic acid to form laurate, adding aluminum chloride to form an enhancer main body organic aluminum phosphate,and carrying out grafting copolymerization by taking ethylene-propylene-dene monomer, methyl methacrylate and acrylonitrile as raw materials to prepare an elastic substance which is wrapped the surface of a talcum powder base material, wherein a plastic matrix molecular chain permeates into grafted copolymer particles to form swelling particles in the melting and blending process of the plastic, the two phases of the commixture can synergistically resist the action of an impact force, and the capability of dissipating impact energy is high, so that the bending modulus and the tensile strengthduring plastic filling are improved. The problems of low bending modulus and low tensile strength when the plastic is filled with the talcum powder at present are solved.

Owner:雷春生

Boiler disincrustant

InactiveCN103756801ACause corrosionEfficient solvencyNon-ionic surface-active compoundsOrganic detergent compounding agentsPhosphateSodium salt

The invention discloses a boiler disincrustant which is prepared from the following raw materials in parts by weight: 5-9 parts of coconut oil ethoxylate, 15-20 parts of sodium dodecyl benzene sulfonate, 2-5 parts of coconut oil diglycollic amide, 1-3 parts of sodium ethylenediamine tetraacetic acid, 3-8 parts of triethanolamine, 1-3 parts of dodecyl phosphate and 60-70 parts of water, wherein the dodecyl phosphate is dodecyl phosphate sylvite or sodium salt. The final pH value of a product of the boiler disincrustant disclosed by the invention is within 7.5-8, so that no corrosion is caused to boiler walls, human skin is not hurt when the boiler disincrustant is used, and the security in operation is improved. Besides, the coconut oil ethoxylate and the coconut oil diglycollic amide added into the product are high in dissolving capacity on boiler dirt and rapid to contaminate.

Owner:SUZHOU CITY BANGCHENG ELECTRICITY TECH

Polyamide spinning finisher

The present invention discloses a polyamide spinning finisher, which comprises a potassium cetyl phosphate, an octyl phosphate diethanolamine salt, a dodecyl phosphate diethanolamine salt and palmitic acid polyethylene glycol ester. The polyamide spinning finisher of the present invention has characteristics of reasonable formula, good use effect and low production cost.

Owner:曹德如

Impact-resisting ceramic tile and preparation method thereof

The invention discloses an impact-resisting ceramic tile and a preparation method thereof. The impact-resisting ceramic tile is composed of the following raw materials in part by weight: 33-46 parts of serpentine, 21-34 parts of illite, 17-29 parts of sericite, 14-22 parts of white paste mud, 18-32 parts of lead zinc slag, 10-15 parts of mung bean rock, 22-28 parts of composite clay, 8-14 parts of sulphurous acid sulfite lye, 3-6 parts of lithium carbonate, 2-4 parts of sodium thiosulfate, 1.5-2.5 parts of dodecyl phosphate glycine betaine, 2-3 parts of carboxymethyl inulin sodium, 10-15 parts of aluminum borate whisker, and 4-7 parts of alkali lead chromate. The ceramic tile prepared by the invention is strong in impact-resisting intensity, high in hardness, low in water absorbent, and good in thermal stability; besides, the impact-resisting ceramic tile has good erosion resistance, seepage resistance, temperature resistance and wear resistance, stable quality, good using effect and durability, and good application prospect.

Owner:安徽省亚欧陶瓷有限责任公司

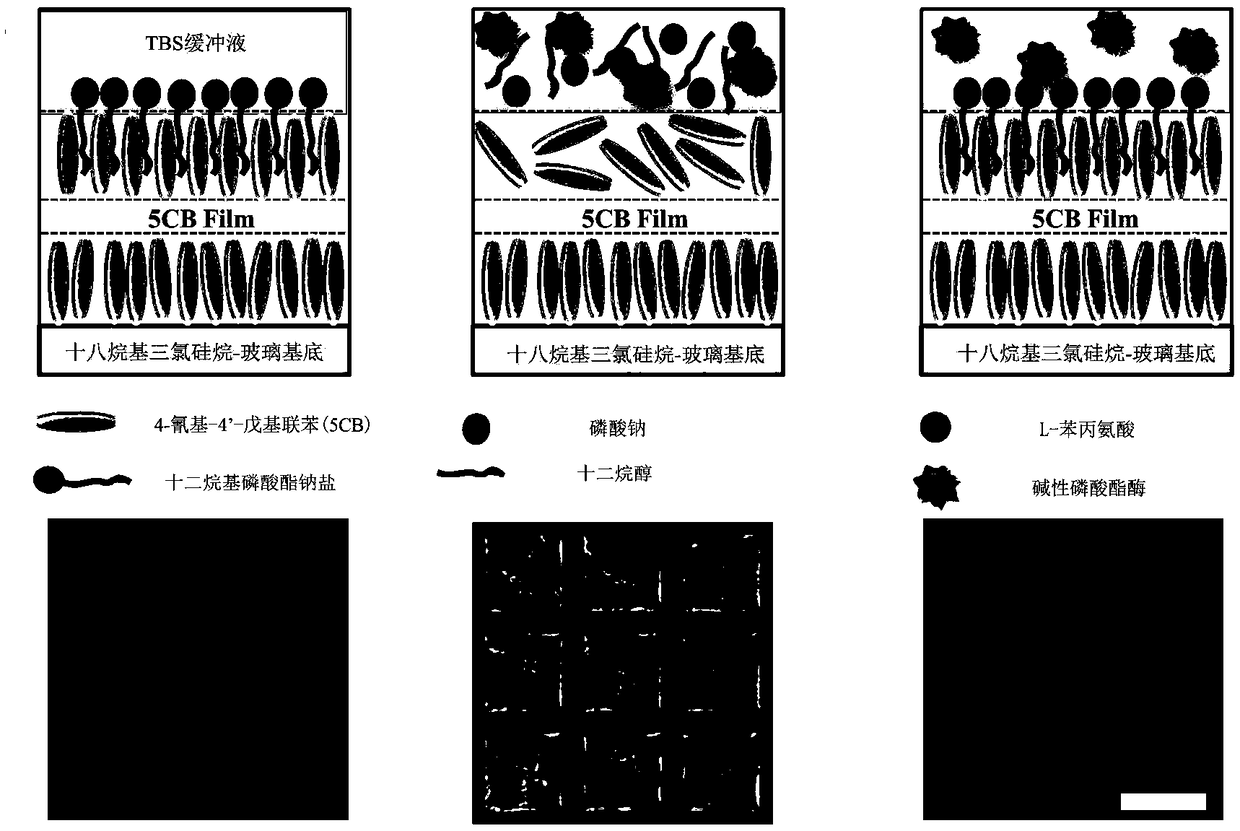

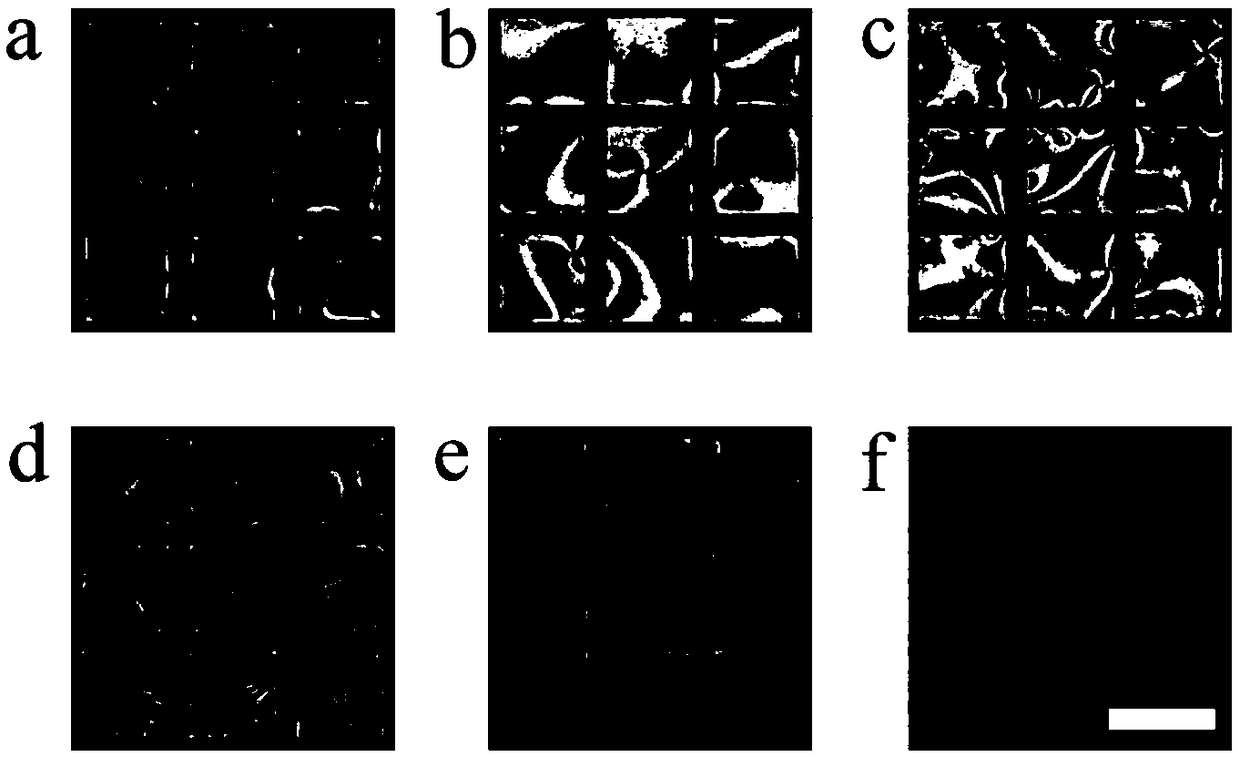

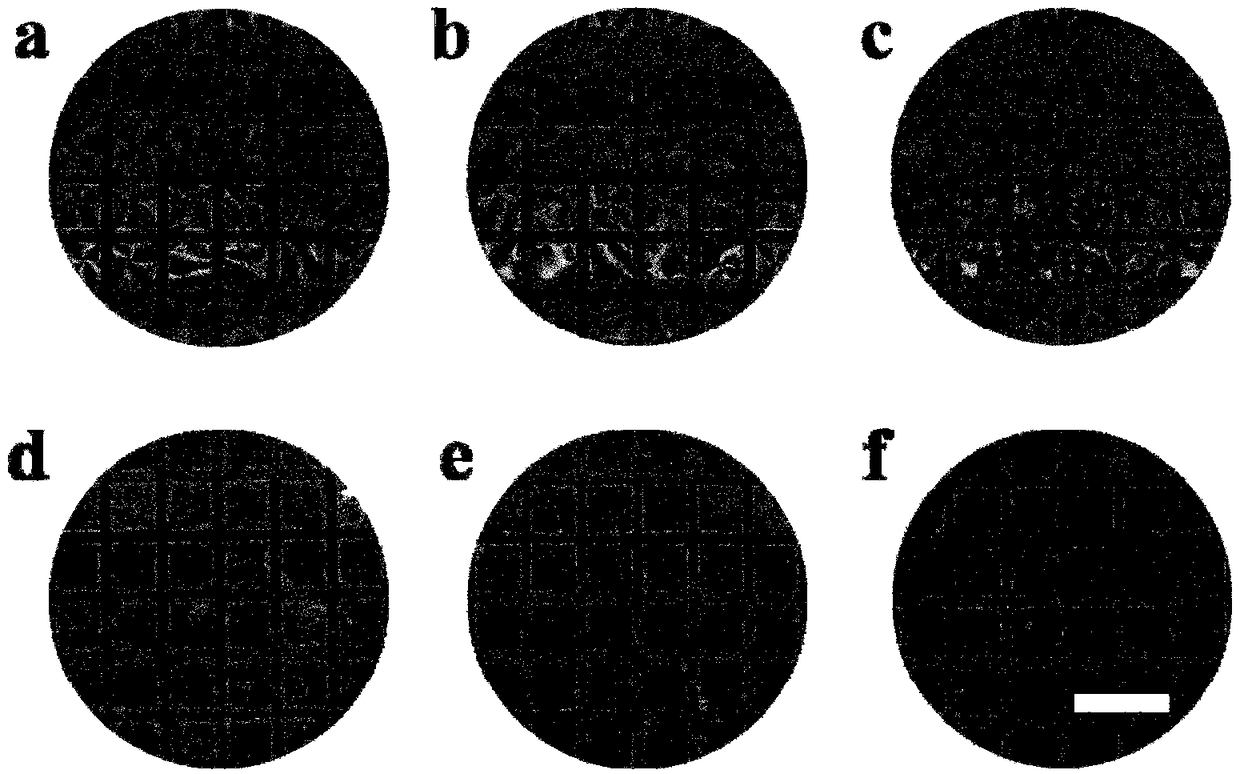

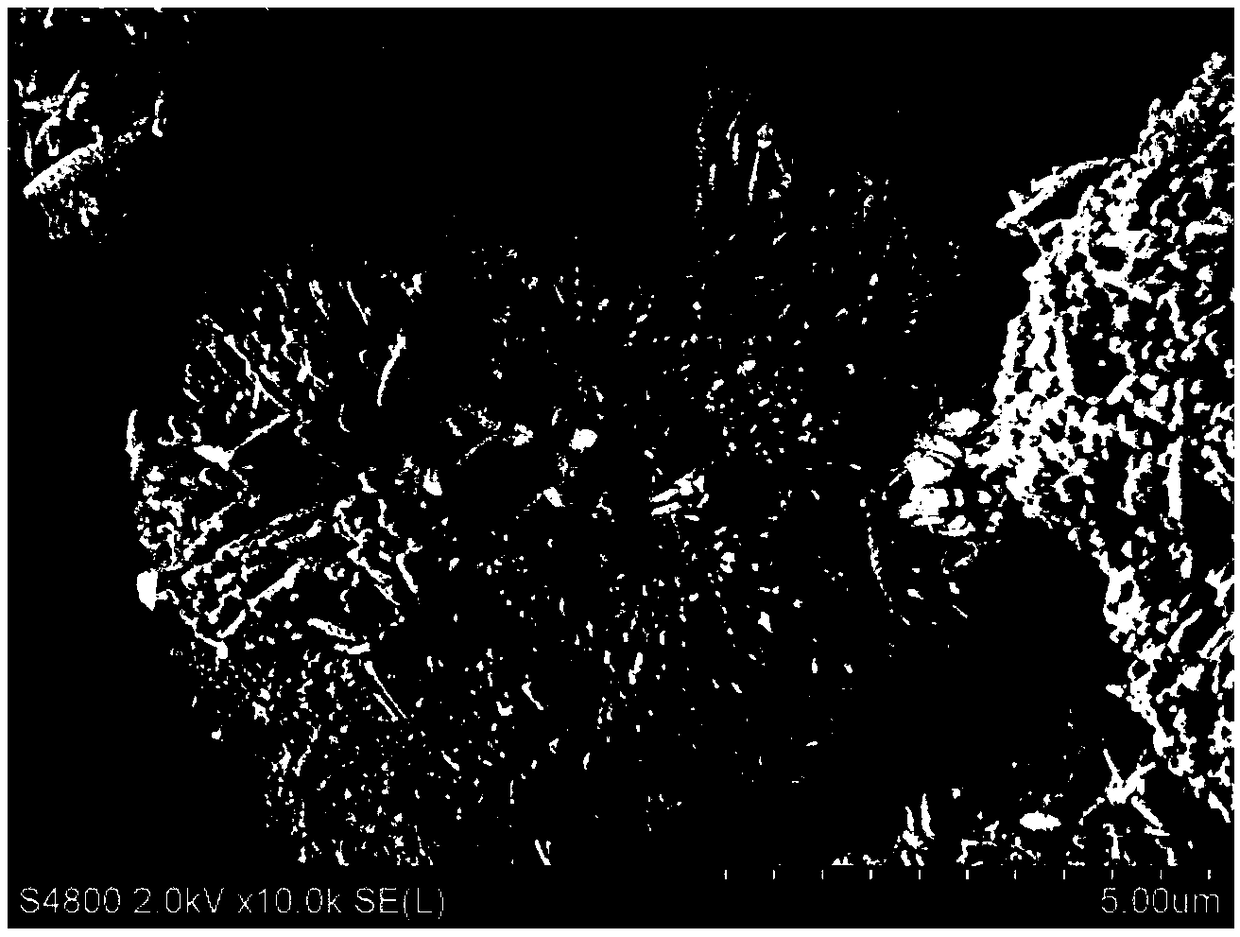

Method for analyzing and detecting L-phenylalanine based on liquid crystal sensor

InactiveCN109187542AShort processing timeLow detection limitMaterial analysis by optical meansPhosphatePhenylalanine

The invention relates to a method for analyzing and detecting L-phenylalanine based on a liquid crystal sensor. The method comprises the following steps: (1) diluting a sample to be tested in a TBS buffer solution to prepare a solution to be tested; (2) adding an alkaline phosphatase solution into the solution to be tested to prepare an enzyme reaction solution after a reaction; and (3) dripping the enzyme reaction solution onto the liquid crystal sensor modified by a sodium lauryl phosphate solution, and performing observation by using a polarizing microscope. The method for analyzing and detecting the L-phenylalanine in the urine of a patient with phenylketonuria based on the liquid crystal sensor provided by the invention has the advantages of low detection limit, easiness to obtain thedetection instrument, simple, rapid and sensitive detection method, less reagent consumption, short sample processing time and the like, the problems that the existing detection method is complicatedand high in cost are solved.

Owner:SHANDONG UNIV

Unified oil for spinning

The invention discloses unified oil for spinning, which is prepared by mixing potassium dodecyl phosphate, C10 acid polyglycol ester, laurinol polyoxyethylene ether and hydrophilic white oil. The unified oil for spinning has the advantages of good using effect, long storage time, and low production cost and can be used as unified oil for spinning polyster fibers.

Owner:蔡云进

Damp-proof waterproof binder for building and preparation method of damp-proof waterproof binder

InactiveCN105036640AImprove water resistanceImprove moisture resistancePhosphoric Acid EstersBetaine

The invention discloses a damp-proof waterproof binder for a building and a preparation method of the damp-proof waterproof binder. The damp-proof waterproof binder is prepared by adopting the following raw materials in part by weight: 80 to 120 parts of ordinary silicate cement, 24 to 38 parts of condensed silica fume, 4 to 8 parts of poly(hydroxyethyl methacrylate), 18 to 26 parts of zirconium silica residue powder, 1 to 3 parts of toluene diisocynate, 0.2 to 0.4 parts of myristyl glucoside, 5 to 10 parts of ardealite, 12 to 18 parts of polyvinyl alcohol, 10 to 15 parts of yellow dextrin, 3 to 5 parts of methyl hydrogen silicone oil, 25 to 35 parts of acetic styrene-acrylic emulsion, 5 to 10 parts of dry sludge powder, 6 to 12 parts of aluminum silicate, 3 to 6 parts of carboxymethylcellulose, 4 to 7 parts of sodium alginate, 3 to 5 parts of nano zirconium boride, 0.3 to 0.5 parts of dodecyl phosphate betaine, 0.2 to 0.4 parts of glycerol monolaurate, 8 to 14 parts of enhancer and an appropriate amount of water. On the basis of excellent damp-proof waterproof performance, the damp-proof waterproof binder for the building is non-toxic, has no organic volatile matter and is harmless to a human body, pollution-free to the environment and high in cohesive force with various base bodies; compared with ordinary cement mortar, the binding strength is greatly improved, no fracture is caused after the binder is used for a long time, and duration can be realized.

Owner:任新年

Lubricating agent for shaft boring machine and preparation method of lubricating agent

InactiveCN104232032AEasy to stickReduce resistanceDrilling compositionFriction reductionMicrocrystalline wax

The invention discloses a lubricating agent for a shaft boring machine and a preparation method of the lubricating agent. The lubricating agent is prepared from the following constituents in parts by weight: 10-20 parts of carnauba wax, 1-5 parts of oleic acid, 0.1-0.9 parts of butylated hydroxytoluene, 1-6 parts of triethanolamine, 20-40 parts of silicon oil, 1-3 parts of microcrystalline wax, 5-10 parts of glycerin, 5-10 parts of wool fat, 1-5 parts of sodium chloride, 3-8 parts of dodecyl oleate, 0.5-2.5 parts of sodium nitrite, 1-3 parts of urea, 1-8 parts of lauryl phosphate, 0.5-1.5 parts of methylacrylic acid, and 2-6 parts of an emulsifying agent. The lubricating agent is low in cost, good in lubricating effect, easy to adhere to the surface of the shaft boring machine, high in adhesive force, capable of forming oil film on the surface to reduce resistance between friction parts and preventing water and steam from entering in the machine, high in water resistance and dirt resistance, low in friction coefficient, and very suitable for the working environment of the shaft boring machine.

Owner:JIANGSU KANG BAISI MECHANICAL TECH

Paint cleaner for fabric

InactiveCN103666874AEfficient removalChemical paints/ink removersSurface-active non-soap compounds and soap mixture detergentsPhosphoric Acid EstersPolyvinyl alcohol

The invention relates to a paint cleaner for fabric, which comprises the following components in parts by mass: 0.5-7 parts of pine oil, 13-24.6 parts of naphtha, 0.2-0.48 parts of tetradecyl benzyl dimethyl ammonium chloride, 0.03-0.05 parts of polyvinyl alcohol, 0.01-0.022 parts of dodecyl phosphate salt, 3.25-9.25 parts of sodium percarbonate, 0.1-0.35 parts of essence and 159-183 parts of water. The invention provides the paint cleaner for the fabric, which can effectively remove paint and other stains from the fabric, kill bacteria on the fabric and allows the cleaned fabric to become soft and antistatic.

Owner:南通信一服饰有限公司

Surface passivation treatment agent for aluminum profile

InactiveCN105331969AExcellent superhydrophobicityHigh barrierMetallic material coating processesPhosphatePolyvinyl alcohol

The invention discloses a surface passivation treatment agent for an aluminum profile. The surface passivation treatment agent is prepared from, by weight, 0.5-1 part of benzotriazole, 5-6 parts of cerous nitrate, 1-2 parts of sodium fluoride, 1.5-2 parts of hydrogen peroxide, 20-24 parts of triethoxyvinylsilane, 1-2 parts of polyving akohol, 1-2 parts of nanometer titania, 2-3 parts of nanometer zirconium dioxide, 5-6 parts of waterborne polyurethane, 0.4-0.5 part of polyvinyl formal, 0.04-0.08 part of dodecyl phosphate ester, 0.2-0.4 part of potassium zirconium carbonate, 0.9-1.2 parts of kaolin, 0.2-0.4 part of ferric chloride and 100-130 parts of deionized water. The process formula is non-poisonous and environment-friendly, ingredients are simple, preparing is convenient, and the treatment process is simple; and the passivation and corrosion prevention effect is good, and actual production is facilitated.

Owner:DANGTU WEISIGONGCHUANG IND PROD DESIGN CO LTD

Body slimming bath milk

InactiveCN106473967AGood effectEasy to rinseCosmetic preparationsMetabolism disorderPhosphateTea leaf extract

The present invention discloses a body slimming bath milk, which comprises, by mass, 30-60 parts of a dodecyl phosphate ester salt, 5-15 parts of avocado oil, 5-10 parts of glycerin, 6-18 parts of a seaweed extract, 1-16 parts of a tea leaf extract, 3-20 parts of a citrus extract, 1-5 parts of cetyl alcohol, and 40-70 parts of water. The body slimming bath milk of the present invention has advantages of skin moisturizing and easy washing out, and can provide the body slimming effect during the bath.

Owner:李尧

Preparation method of ball-cluster-shaped light calcium carbonate

ActiveCN108793217AUniform shapeUniform particle size distributionCalcium/strontium/barium carbonatesDispersityPhosphate

The invention discloses a preparation method of ball-cluster-shaped light calcium carbonate. The preparation method comprises the following steps: calcining quick lime to generate slaked lime; carrying out digestion reaction on the slaked lime and water to obtain lime slurry; ageing, sieving, removing impurities and diluting until the solid content is 10 to 13 percent, so as to obtain a Ca(OH)2 suspension solution; then adding a first crystal form regulation and control agent and a second crystal form regulation and control agent; stirring and uniformly mixing to obtain a mixed suspension solution, wherein the first crystal form regulation and control agent is one or more of dodecyl phosphate triethanolamine, dodecyl phosphate and hexadecyl glucoside and the second crystal form regulationand control agent is one or more of sodium N-lauroylsarcosinate, sodium N-lauroylglutamate and polysorbate; introducing carbon dioxide gas into the mixed suspension solution and carrying out carbonization reaction; when the PH (Potential of Hydrogen) value of the slurry is reduced to 7.0 to 7.5, stopping reaction; then dehydrating, drying, crushing and sieving to obtain a calcium carbonate product. According to the preparation method, the ball-cluster-shaped light calcium carbonate with a uniform shape and good dispersity is prepared and calcium carbonate with different shapes are explored; the preparation method has a good application prospect.

Owner:GUANGXI SHANDONGLAI CHEM IND TECH CO LTD

Non-amine asphalt anti-stripping agent and preparation method thereof

The invention discloses a non-amine asphalt anti-stripping agent, which is prepared from the following components in parts by weight: 50 to 60 parts of paraffin, 20 to 30 parts of oleic acid, 20 to 30 parts of sodium dodecyl phosphate, 50 to 60 parts of molecular sieves, 4 to 6 parts of long-chain organic silane, 3 to 7 parts of amino silane, 4 to 10 parts of antioxidants, 2 to 4 parts of phosphorus pentoxide and 1 to 3 parts of manganese dioxide. The non-amine asphalt anti-stripping agent provided by the invention can effectively improve the adhesion of a pavement asphalt material to various stones, improve the aging resistance of the pavement asphalt material and prolong the service life of the pavement asphalt material.

Owner:四川科路泰交通科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com