Styrene-acrylic emulsion for repainting primer and preparation method of styrene-acrylic emulsion

A technology of styrene-acrylic emulsion and primer, which is applied in the direction of coating, etc., can solve the problems that the primer cannot be directly used to pulverize the wall surface, change the loose surface strength of the substrate, etc., and achieve convenient and quick recoating, improved density, The effect of high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

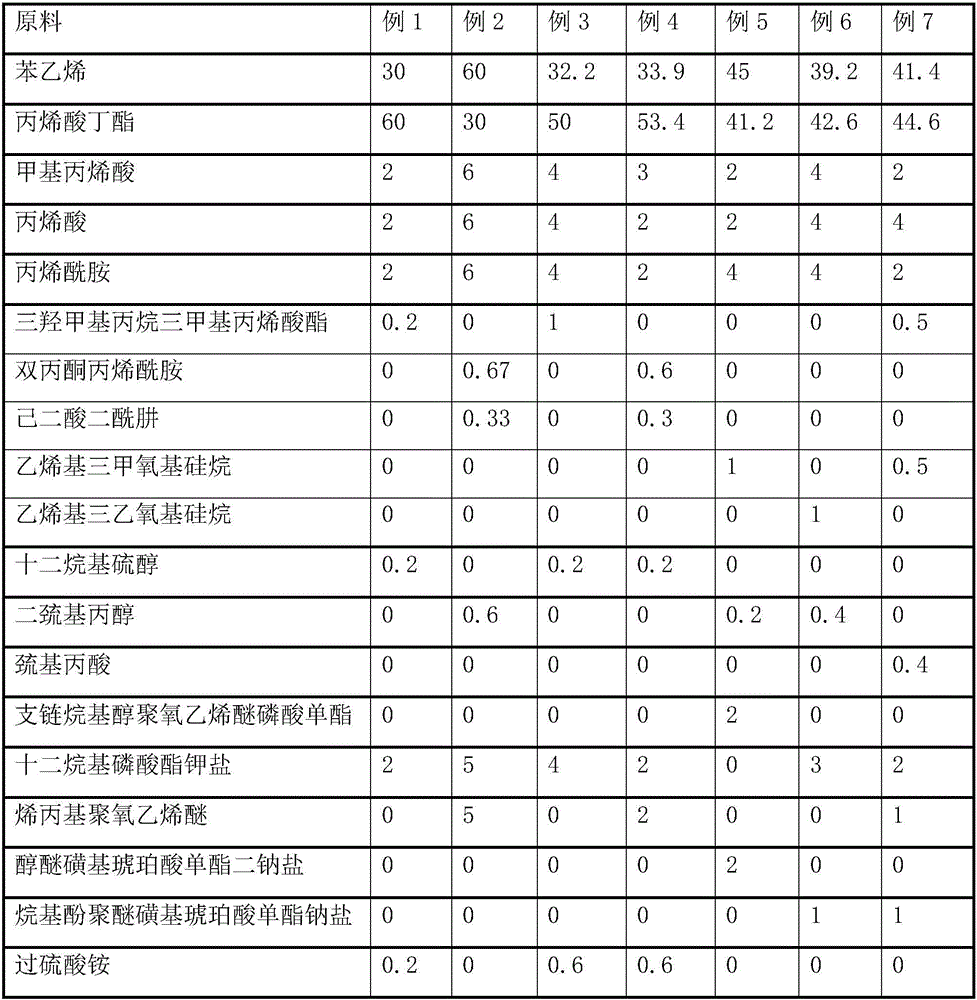

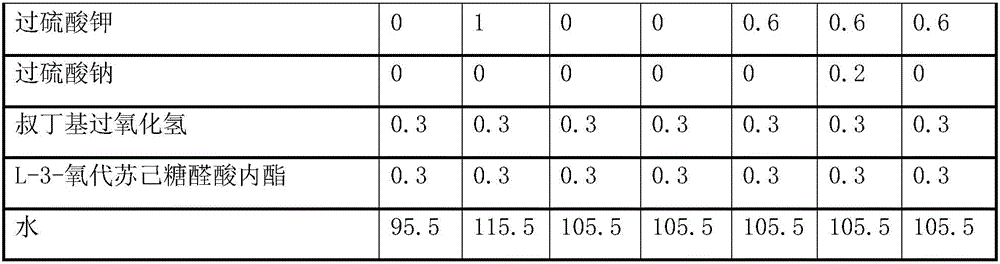

[0039] A kind of preparation method of styrene-acrylic emulsion for recoating primer, is prepared by comprising the following steps carried out in sequence:

[0040] a. At room temperature, add 1.4-8 parts of emulsifier and 50-60 parts of water into the emulsification tank with a cross paddle, stir at a speed of 60-70 rpm, stir for 30 minutes to make it evenly mixed, Add 30-60 parts of styrene, 30-60 parts of butyl acrylate, 2-6 parts of methacrylic acid, 2-6 parts of acrylic acid, 2-6 parts of acrylamide and 0.2-1 part of cross-linking monomer in sequence under stirring at the same speed , 0.2-0.6 parts of chain transfer agent, stirred for 30 minutes to make it evenly mixed, and then the emulsion was prepared and set aside.

[0041] b. Add 0.6-2 parts of emulsifier and 40-50 parts of water into the reaction kettle, stir at 40-45 rpm for 30 minutes to mix evenly, raise the temperature to 85-87°C, and keep stirring during the whole heating process.

[0042] c. Dissolve 0.06-0....

Embodiment 1

[0057] A kind of preparation method of styrene-acrylic emulsion for recoating primer, is prepared by comprising the following steps carried out in sequence:

[0058] a. At room temperature, add 1.4 parts of potassium dodecyl phosphate and 50 parts of water into an emulsification tank with a cross paddle, stir at a speed of 60-70 rpm, and stir for 30 minutes to make it evenly mixed Finally, add 30 parts of styrene, 60 parts of butyl acrylate, 2 parts of methacrylic acid, 2 parts of acrylic acid, 2 parts of acrylamide, 0.2 parts of trimethylolpropane trimethacrylate, dodecane 0.2 part of base mercaptan, stirred for 30 minutes to make it evenly mixed, that is, an emulsion was prepared and set aside.

[0059] b. Add 0.6 parts of potassium dodecyl phosphate and 40 parts of water into the reaction kettle, stir at 40-45 rpm for 30 minutes to mix evenly, raise the temperature to 85°C, and keep stirring during the whole heating process.

[0060] c. Dissolve 0.06 part of ammonium persu...

Embodiment 2

[0067] A kind of preparation method of styrene-acrylic emulsion for recoating primer, is prepared by comprising the following steps carried out in sequence:

[0068] a. At room temperature, add 8 parts of emulsifier and 60 parts of water into the emulsification tank with a cross paddle, stir at a speed of 60-70 rpm, stir for 30 minutes to make it evenly mixed, then stir at the same speed Add 60 parts of styrene, 30 parts of butyl acrylate, 6 parts of methacrylic acid, 6 parts of acrylic acid, 6 parts of acrylamide, 1 part of crosslinking monomer, and 0.6 parts of dimercaptopropanol in sequence, and stir for 30 minutes to make it evenly mixed. That is, the emulsion is prepared and set aside.

[0069] b. Add 2 parts of emulsifier and 50 parts of water into the reaction kettle, stir at 40-45 rpm for 30 minutes to mix evenly, raise the temperature to 87°C, and keep stirring during the whole heating process.

[0070] c. Dissolve 0.3 part of potassium persulfate with 0.5 part of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com