Preparation method of ball-cluster-shaped light calcium carbonate

A light calcium carbonate, cluster technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc. Difficult to control and other problems, to achieve uniform morphology, uniform particle size distribution, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

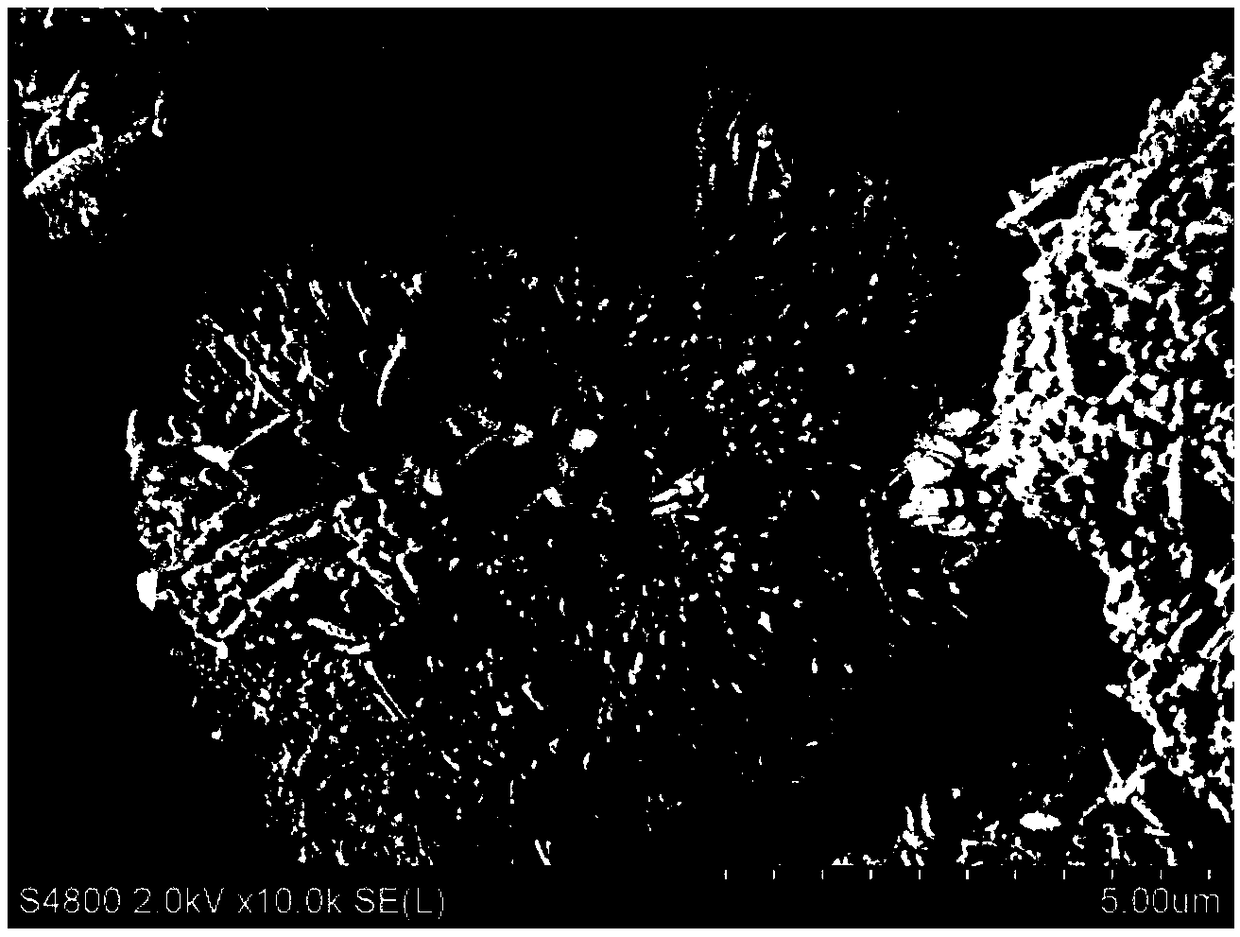

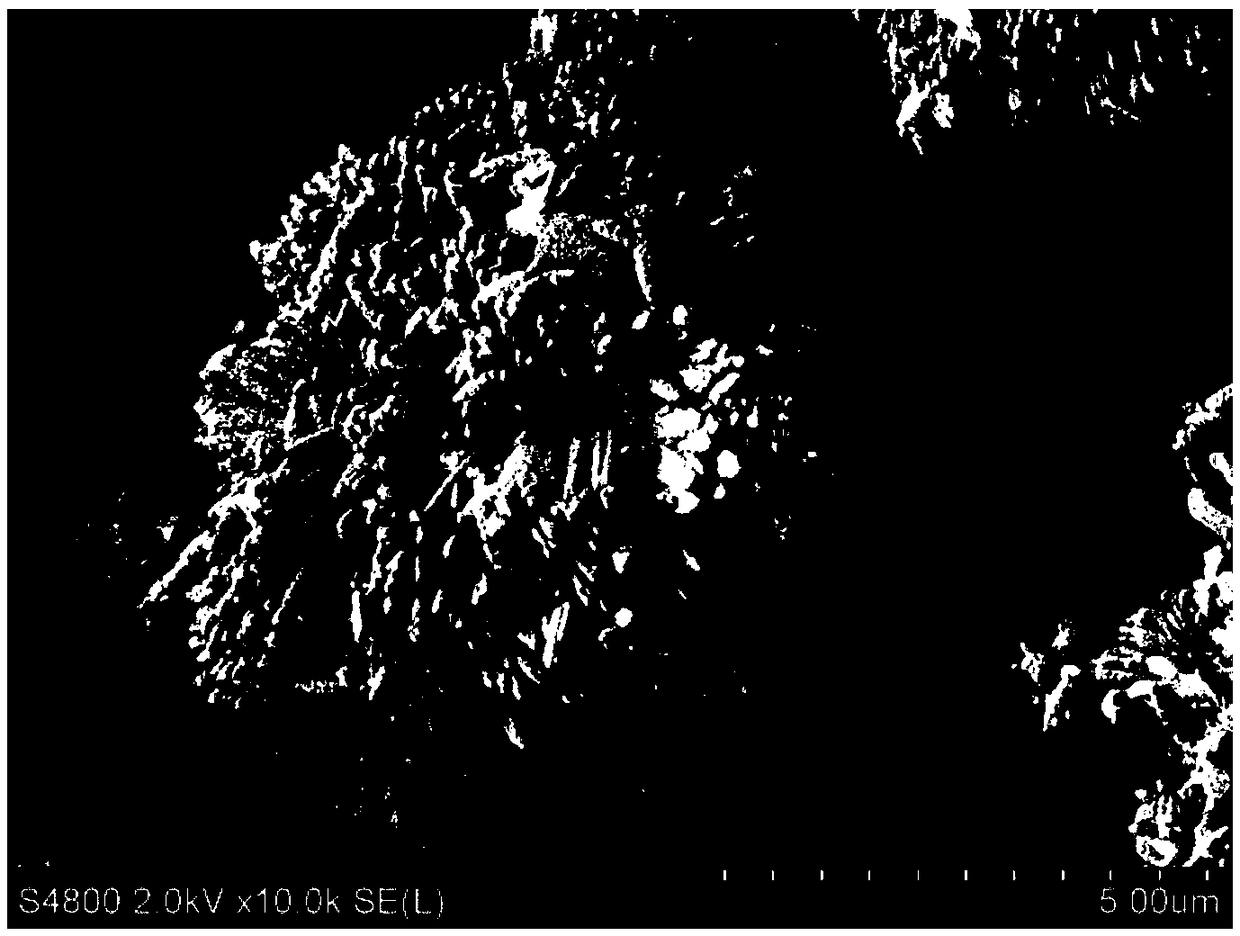

Image

Examples

Embodiment 1

[0028] A preparation method of spherical cluster-shaped light calcium carbonate, comprising the following processing steps:

[0029] (1) Calcining quicklime at 1100°C for 5 hours to turn quicklime into quicklime, then digest quicklime and water at a mass ratio of 1:8 to obtain lime slurry. After 24 hours, pass through a 150-mesh sieve to remove impurities, and then dilute the lime slurry to a solid content of 13% to obtain Ca(OH) 2 suspension;

[0030] (2) In the Ca(OH) obtained in step (1) Adding the first crystal form regulator and the second crystal form regulator with a mass ratio of 2:1 to the Ca(OH) suspension, stirring for 30min at a rotating speed of 500r / min, Obtain a mixed suspension; the total addition of the crystal form regulator is Ca(OH) 1% of the suspension quality, and the first crystal form regulator is a dodecyl phosphate triethanolamine solution with a mass concentration of 5%. , the second crystal form regulator is a sodium N-lauroyl amate solution with ...

Embodiment 2

[0035] A preparation method of spherical cluster-shaped light calcium carbonate, comprising the following processing steps:

[0036] (1) Calcining quicklime at 1200°C for 4 hours to turn quicklime into quicklime, then digest quicklime and water at a mass ratio of 1:7 to obtain lime slurry. After 24 hours, pass through a 150-mesh sieve to remove impurities, and then dilute the lime slurry to a solid content of 11.5% to obtain Ca(OH) 2 suspension;

[0037] (2) In the Ca(OH) obtained in step (1) Adding the first crystal form regulator and the second crystal form regulator with a mass ratio of 2:1 to the Ca(OH) suspension, stirring at a rotating speed of 500r / min for 25min, Obtain a mixed suspension; the total addition of the crystal form regulator is Ca(OH) 5% of the suspension quality, the first crystal form regulator is a dodecyl phosphate salt solution with a mass concentration of 5%, The second crystal form regulator is sodium N-lauroylcobalamin solution with a mass concent...

Embodiment 3

[0042] A preparation method of spherical cluster-shaped light calcium carbonate, comprising the following processing steps:

[0043] (1) Calcining quicklime at 1300°C for 4 hours to turn quicklime into quicklime, then digest quicklime and water at a mass ratio of 1:7 to obtain lime slurry. After 48 hours, pass through a 150-mesh sieve to remove impurities, and then dilute the lime slurry to a solid content of 12.5% to obtain Ca(OH) 2 suspension;

[0044] (2) In the Ca(OH) obtained in step (1) Adding the first crystal form regulator and the second crystal form regulator with a mass ratio of 2:1 to the Ca(OH) suspension, stirring for 20min at a rotating speed of 800r / min, Obtain a mixed suspension; the total addition of the crystal form regulator is Ca(OH) 3% of the suspension quality, the first crystal form regulator is a cetyl glucoside solution with a mass concentration of 5%, and the second The dimorph regulator is sodium N-lauroylcobalamin solution with a mass concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com