High-performance magnetic-conductive alloy for electroacoustic device, and preparation method of high-performance magnetic-conductive alloy

An electro-acoustic device, high-performance technology, applied in the direction of electrical components, circuits, magnetic materials, etc., to achieve the effect of improving sound intensity and sound quality, improving magnetic field strength and temperature stability, and increasing temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further elaborated below in conjunction with the drawings and examples.

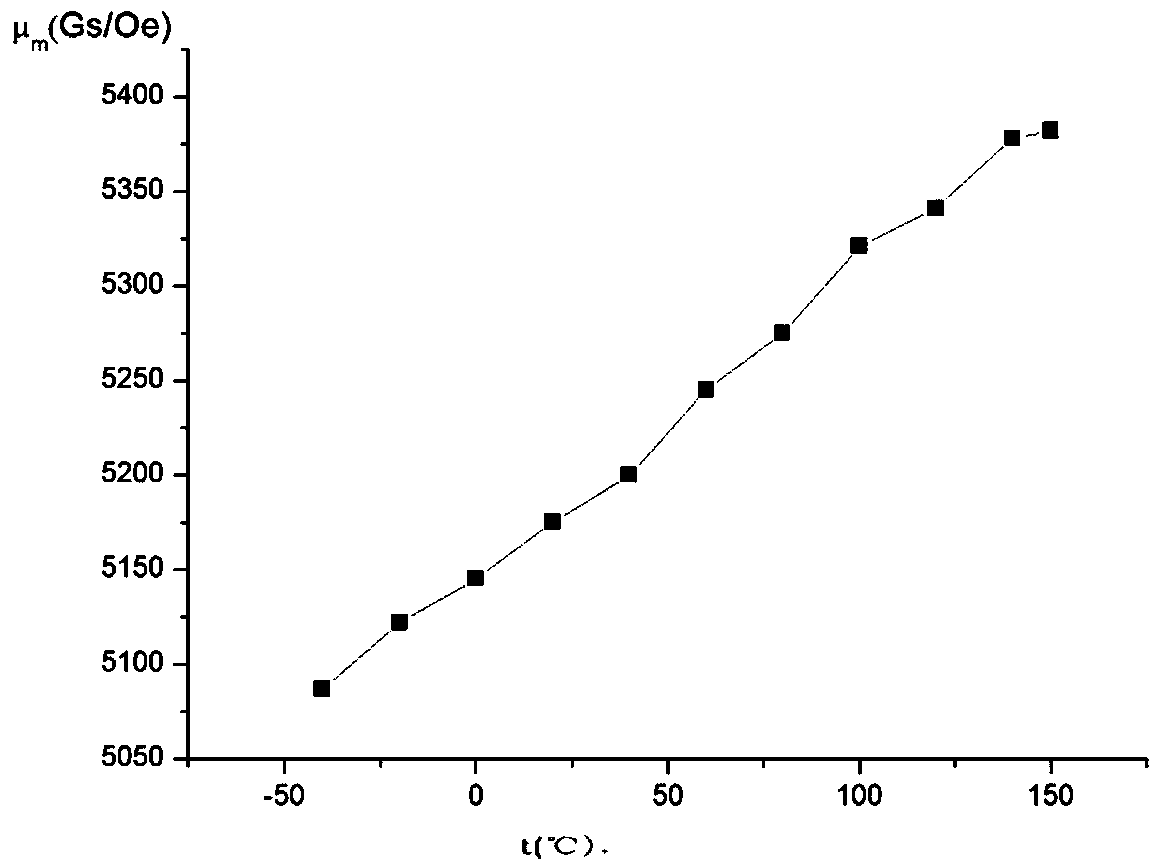

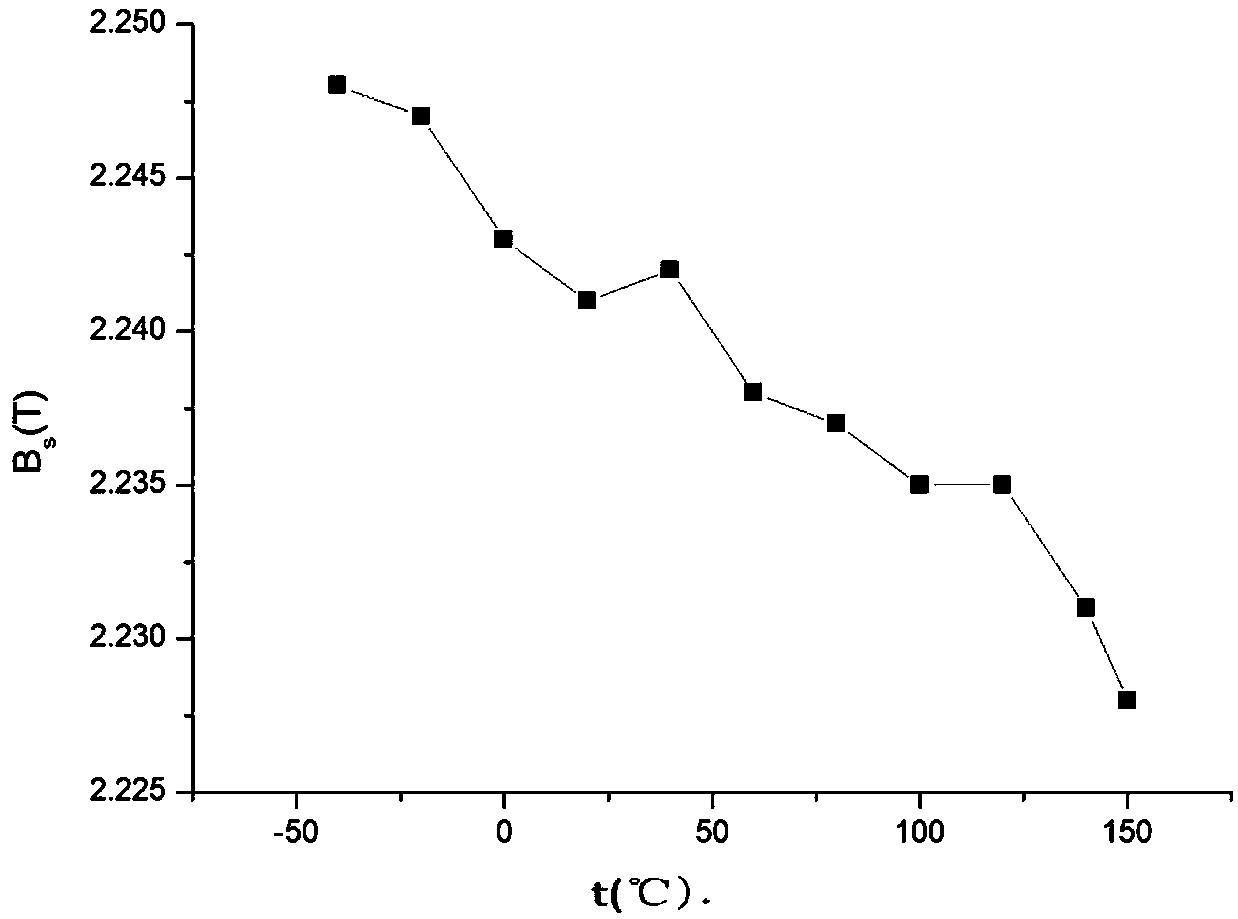

[0027] A high-performance magnetically permeable alloy for electroacoustic devices, the chemical composition of the alloy is Co: 20.0-40.0wt%, B: 0.2-1.5wt%, Mn: 0.10-0.25wt%, Zr: 2.0-4.0wt% %, Ni: 0.2~1.0wt%, V: 1.0~2.5wt%, Si≤0.15wt%, Cu≤0.2wt%, C≤0.01wt%, P≤0.01wt%, S≤0.01wt%, balance For Fe.

[0028] Table 1 is the chemical composition table (wt%) of five embodiments of above-mentioned alloy

[0029] Numbering

co

B

Ni

V

mn

Zr

Si

Cu

C

P

S

Fe

Example 1

38.05

0.22

0.52

1.8

0.18

2.58

0.015

0.04

0.0023

0.0049

0.0031

Remain

Example 2

37.69

0.25

0.58

1.9

0.19

2.14

0.016

0.05

0.0027

0.0055

0.0040

Remain

Example 3

36.19

0.28

0.54

1.8

0.21

2.21

0.015

0.04

0.0028

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com