Supercritical carbon dioxide Brayton cycle power component cooling, sealing and heat insulation system

A technology of Brayton cycle and power components, applied in the direction of electric components, engine components, cooling/ventilation devices, etc., can solve the safety impact of power components, increase the complexity of the system, and cannot effectively solve the heat conduction problems of turbine and motor shafts, etc. problem, to achieve the effect of high system security and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

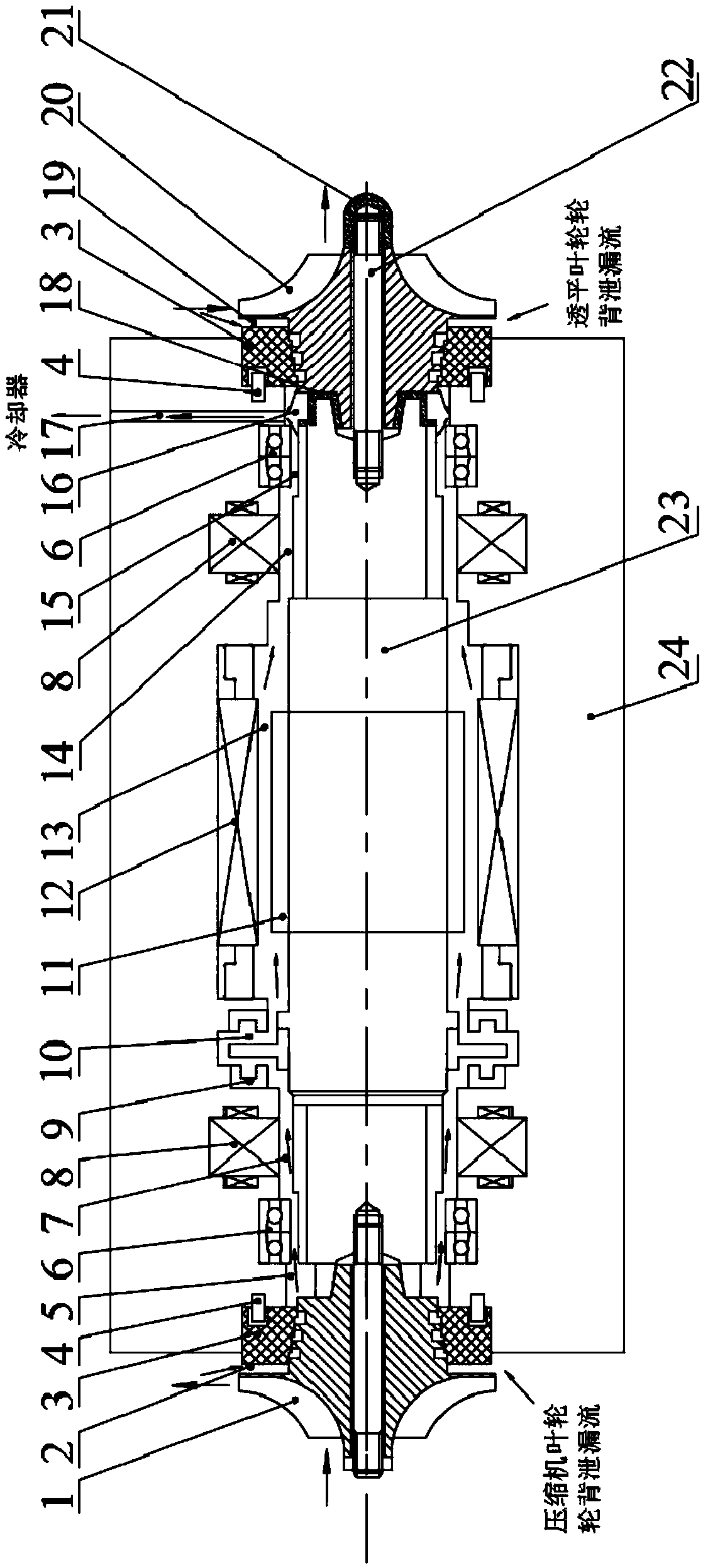

[0029] The invention provides a supercritical carbon dioxide Brayton cycle power component cooling sealing heat insulation system such as figure 1 As shown, the cooling, sealing and heat insulation system includes the back leakage gap 2 of the compressor impeller wheel, the wearable graphite labyrinth seal 3 arranged at both ends of the casing 24, a plurality of sequentially arranged and connected cooling passages, and a cold and hot working medium mixing chamber 16. Vent hole 17, heat insulation sleeve 18, leakage gap 19 at the back of turbine impeller wheel, connecting rod 22 and heat insulation diversion nut 21. The carbon dioxide circulating working fluid that enters the cooling channel through the back leakage gap 2 of the impeller of the compressor and the labyrinth seal is used as the cooling working fluid of the cooling sealing and heat insulation system.

[0030] Pins 4 are arranged on the casing 24, and the pins 4 are closely matched with the casing 24. The length of...

Embodiment 2

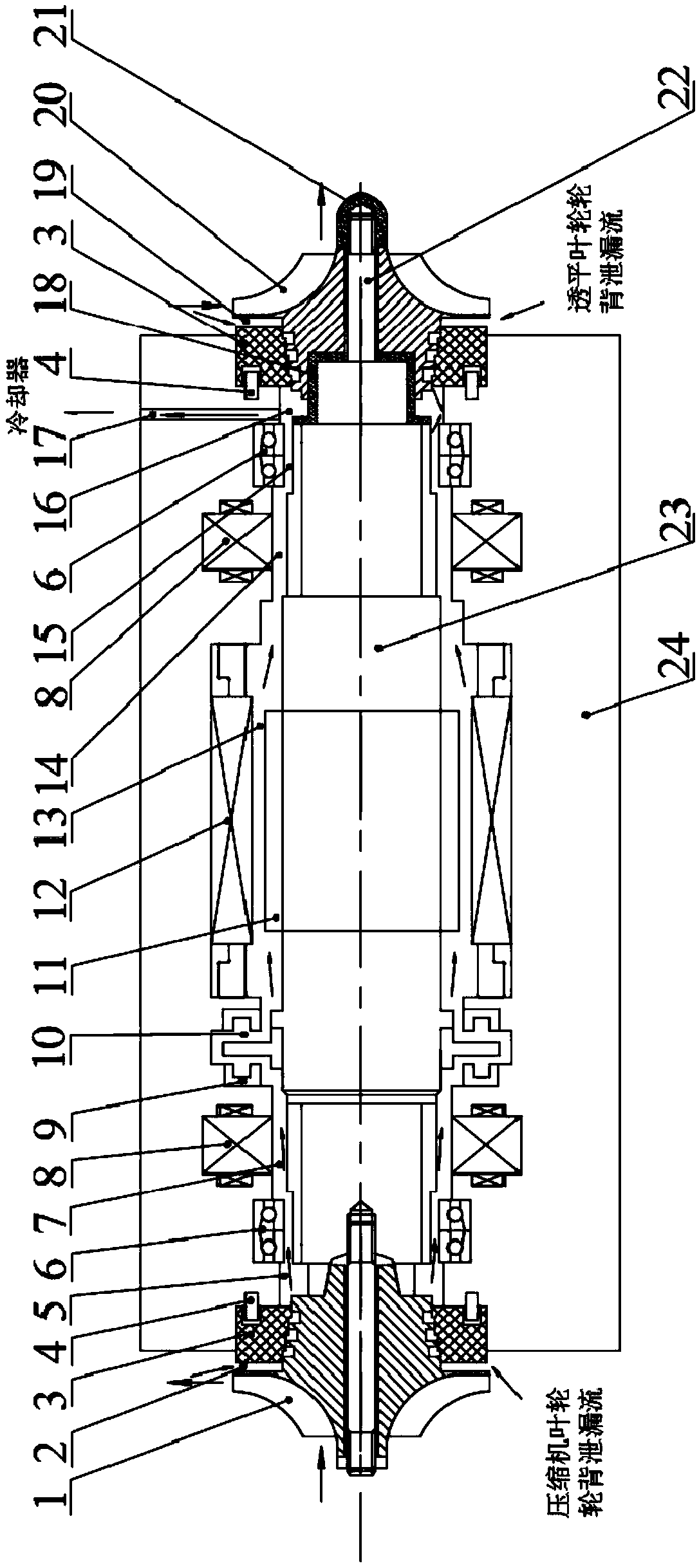

[0035] see figure 2 , the heat insulation sleeve 18 is located between the main shaft 23 and the turbine impeller 20, and is arranged on the end face of the main shaft 23 through an interference fit or threaded connection. The heat insulation sleeve 18 extends inward from the end of the main shaft 23 until the heat insulation The side of the sleeve 18 covers the side area of the main shaft where the cold and hot working medium mixing chamber 16 is located. The heat insulating sleeve 18 completely separates the main shaft 23 from the high-pressure thermal fluid and the turbine impeller 20 to avoid direct contact with the main shaft 23 . The connecting rod 22 is fixed on the main shaft 23 , and the center line of the main shaft 23 coincides with the center line of the connecting rod 22 . The turbine impeller 20 is connected with the heat insulation sleeve 18 through an interference fit, the connecting rod 22 runs through the turbine impeller, the turbine impeller 20 does not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com