Processing method

A processing method and a technology of processed objects, which are applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of rising manufacturing costs and generation of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

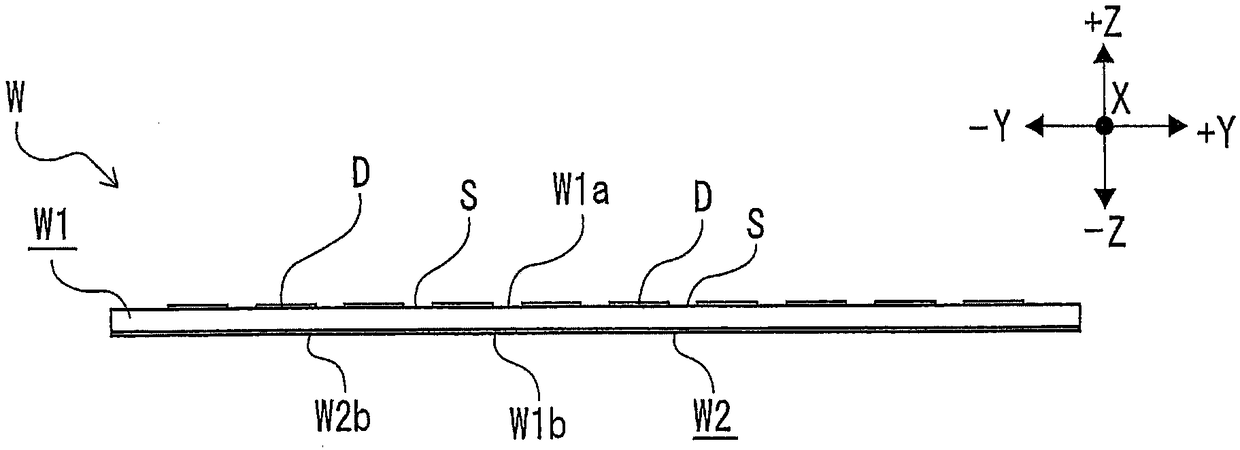

[0024] Below, implement the processing method of the present invention by figure 1 Each step of the processing method for producing a chip having the device D from the workpiece W shown will be described.

[0025] (1-1) Groove forming process using a cutting device

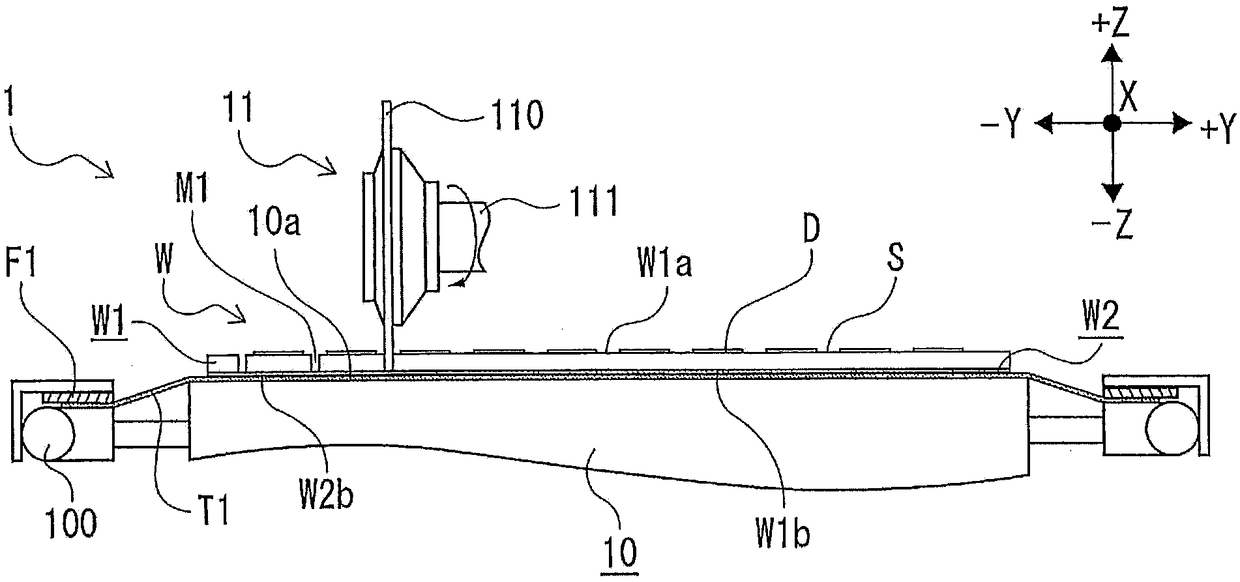

[0026] First, implement the groove forming step from figure 1 Grooves are formed on the front surface W1a of the workpiece W shown along lines S to be divided. In this groove forming step, for example, using figure 2 The cutting device 1 shown is used for groove formation.

[0027] When forming grooves, such as figure 2 As shown, the workpiece W is in the following state: a dicing tape T1 having a diameter larger than the workpiece W is attached to the back surface W2b of the workpiece W, and the outer peripheral portion of the adhesive surface of the dicing tape T1 is attached to the ring frame. on F1. And the workpiece W in the state where the front surface W1a is exposed upward is supported by the ring ...

Embodiment approach 2

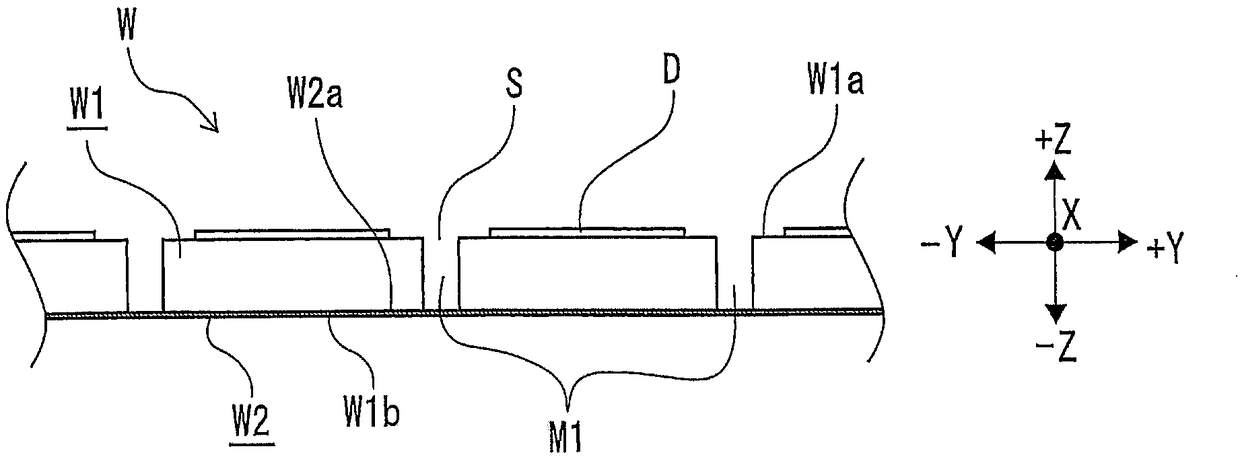

[0081] Below, implement the processing method of the present invention by figure 1 Each step of the processing method for producing a chip having the device D from the workpiece W shown will be described. In Embodiment 2 of the processing method of the present invention, as in Embodiment 1 of the processing method of the present invention, first, (1-1) a groove forming step using a cutting device or (1-2) a step of forming a groove using a plasma etching device is performed. Any step in the groove forming step such as image 3 As shown, grooves M1 whose depth does not reach the film W2 are formed on the workpiece W along all the planned dividing lines S.

[0082] (2) Hold step

[0083] After performing either of (1-1) the groove forming step using the cutting device 1 or (1-2) the groove forming step using the plasma etching device 9, as Figure 5 As shown in , stick the protective tape T3 on the front W1a of the workpiece W, and place the figure 2 Scribe Tape T1 as shown o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com