Silicon-carbon negative pole material for lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of poor cycle performance and inability to cure the cycle performance of silicon-carbon materials, etc., to achieve long-term Effects of Cyclic Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

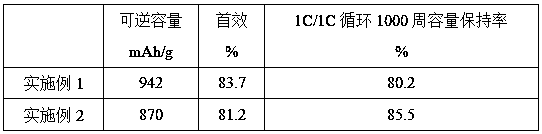

Examples

Embodiment 1

[0024] The preparation method of silicon carbon negative electrode material, the steps are as follows:

[0025] S1. At 2000rpm, disperse nano-silicon and conductive agent into biomass third-grade tar. The mass ratio of silicon, conductive agent and tar is 1:15:20. In the biomass third-grade tar used, the mass of aromatic hydrocarbons The ratio is 32%, the mass ratio of phenols is 28%, and the stirring time is 20h;

[0026] S2. Put the dispersed suspension in an argon atmosphere, let it stand and treat it at a constant temperature of 200°C for 2h;

[0027] S3. Under an argon atmosphere, the above suspension was further heated to 400° C. for 2 hours of constant temperature heat treatment, and the stirring speed was 10 rpm;

[0028] S4. Keep the argon atmosphere, temperature and stirring speed constant, increase the system pressure to 7atm, keep the temperature constant for 24h, and then heat filter to obtain the silicon carbon precursor;

[0029] S5. The silicon-carbon precurs...

Embodiment 2

[0031] The preparation method of silicon carbon negative electrode material, the steps are as follows:

[0032] S1. At 3000rpm, disperse nano-silicon and conductive agent into biomass third-grade tar. The mass ratio of silicon, conductive agent and tar is 1:25:15. In the biomass third-grade tar used, the mass of aromatic hydrocarbons The ratio is 32%, the mass ratio of phenols is 28%, and the stirring time is 10h;

[0033] S2. Put the dispersed suspension in a nitrogen atmosphere, let it stand and treat it at a constant temperature of 300°C for 8h;

[0034] S3. Under a nitrogen atmosphere, the above-mentioned suspension was further heated to 450 ° C for 4 hours of constant temperature heat treatment, and the stirring speed was 30 rpm;

[0035] S4. Keep the nitrogen atmosphere, temperature and stirring speed constant, increase the system pressure to 20atm, keep the temperature constant for 48h, and then heat filter to obtain the silicon carbon precursor;

[0036] S5. Stir the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com