Household garbage crushing, screening and drying integrated machine

A technology for domestic waste and crusher, applied in dryers, drying, drying gas layout, etc., can solve the problems of large infrastructure investment, large area and huge equipment, and achieve small infrastructure investment and equipment consumption. Low energy and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

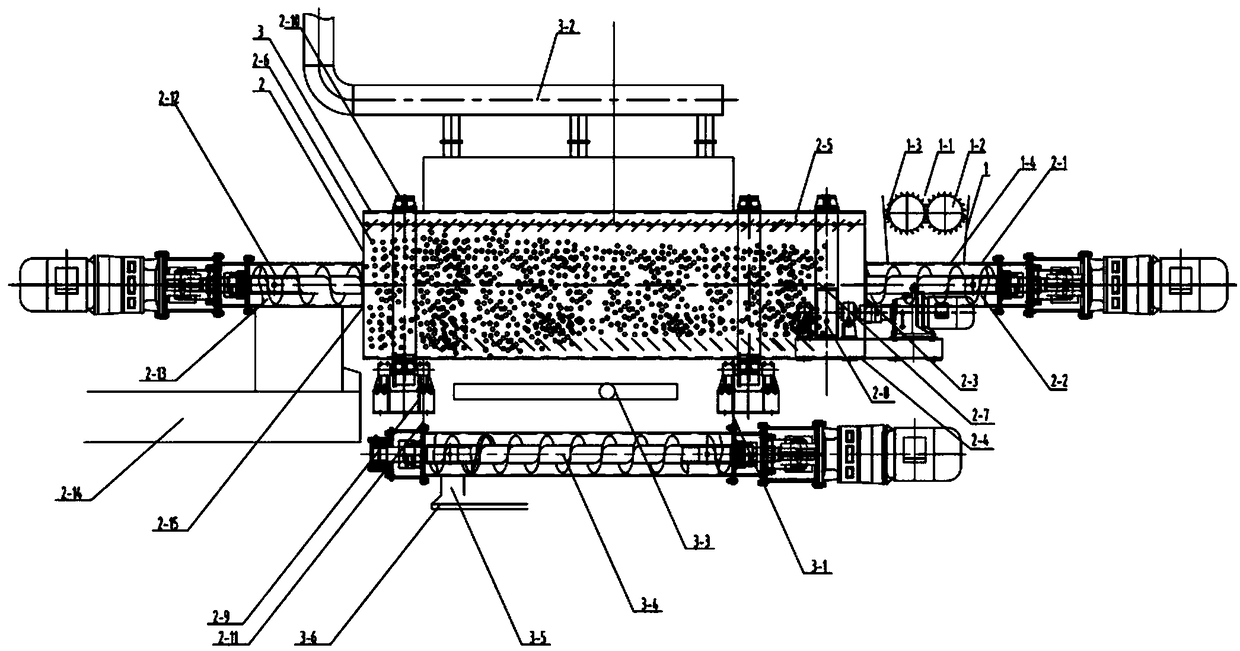

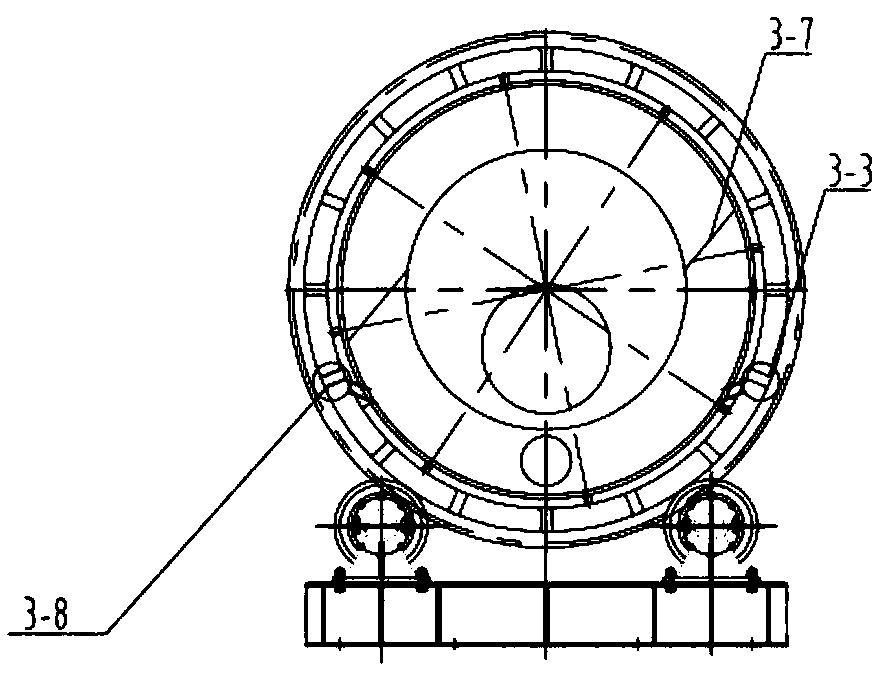

[0020] Example 1, such as figure 1 , figure 2 Shown:

[0021] The wolf tooth extrusion crusher 1 is installed above the feed port 2-1 of the drum sorting screen 2, and the discharge port 1-4 of the domestic waste crusher 1 is connected to the flange of the drum sorting screen 2 feed port 2-1 Connection, the upper part of the domestic waste crusher 1 has the upper part is the upper, lower and small inclined feed port 1-1, the middle and lower part is the double-rotary extrusion type wolf tooth-shaped crushing knife 1-2, the rotary extrusion type wolf-tooth-shaped crushing knife There are fixed knives 1-3 on one side of the outer wall and its corresponding parts, and one end of the double-rotating extrusion type wolf tooth-shaped crushing knives 1-2 is fixed on the support, and the other end is connected with the reducer.

[0022] The shell of the drum sorting screen 2 is a porous circular body 2-4, which is installed horizontally, with a material guide plate 2-5 installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com