Three-stage heating process method for forging blank

A heating process and process method technology, applied in the field of heating process, can solve the problem of difficult control of the temperature of metal blanks, and achieve the effects of uniform internal and external temperature distribution, saving time and ensuring physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

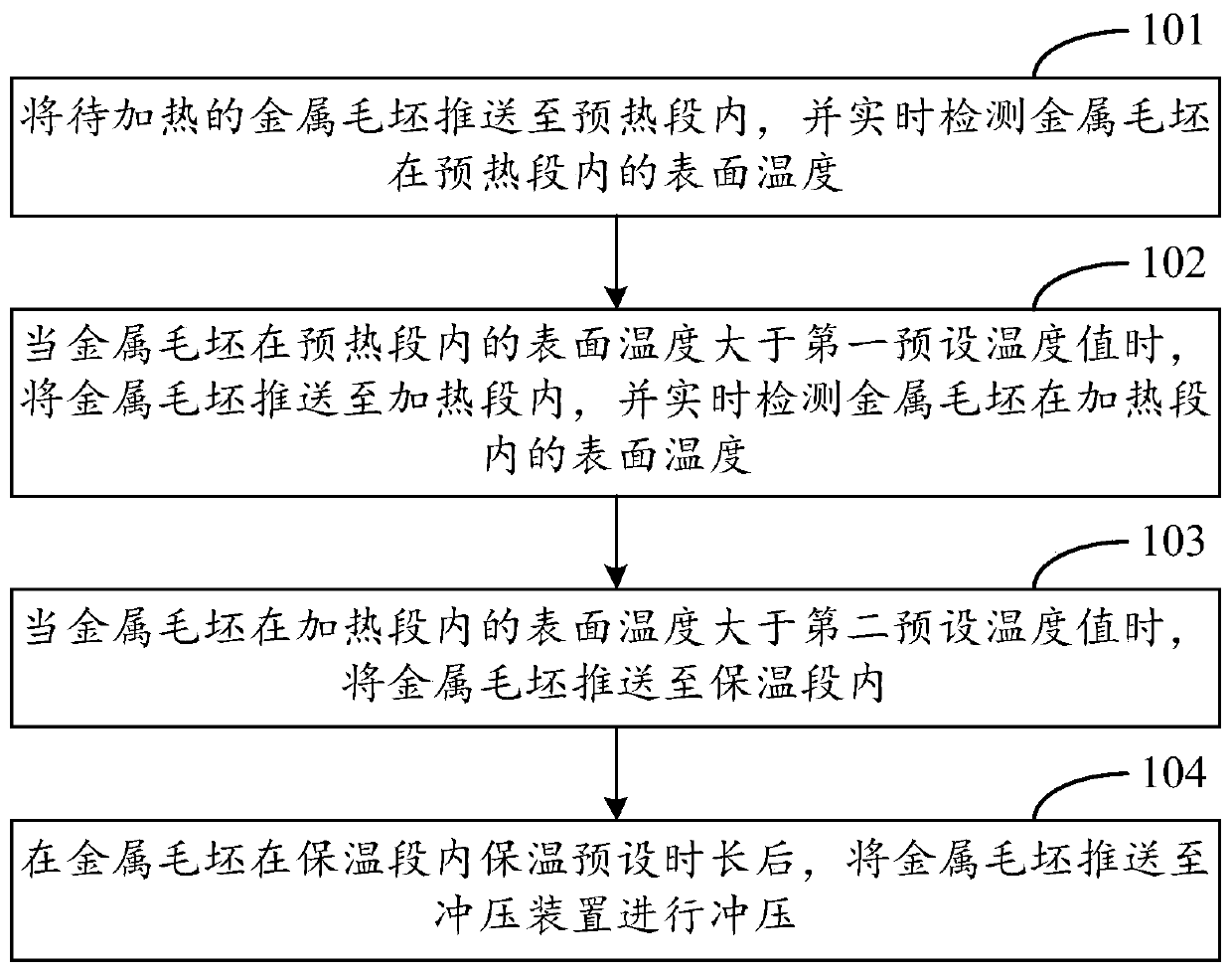

[0040]The embodiment of the present invention provides a three-stage heating process for forging blanks, which can accurately control the temperature of metal blanks (that is, forging blanks). The heating equipment for implementing the process method specifically includes three parts: a preheating section and a heating section. and heat preservation section, and the preheating section, heating section and heat preservation section are arranged in an integral structure, that is, the three sections can be integrated, but each section has different functions, or the three sections are connected in sequence, such as seamless connection, etc.; to be heated The metal blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com