High-temperature superconductive vacuum pipeline traffic system with suspension and driving system arranged externally and smooth inner wall

A drive system, high-temperature superconducting technology, applied in tunnel systems, tracks, roads, etc., can solve the problem of not giving specific solutions for pipe wall structure and vehicle installation, not being able to achieve supersonic speed, super high speed, and not giving thin walls Pipeline strengthening and other issues to achieve the effect of reducing construction and operating costs, reducing requirements, and eliminating heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

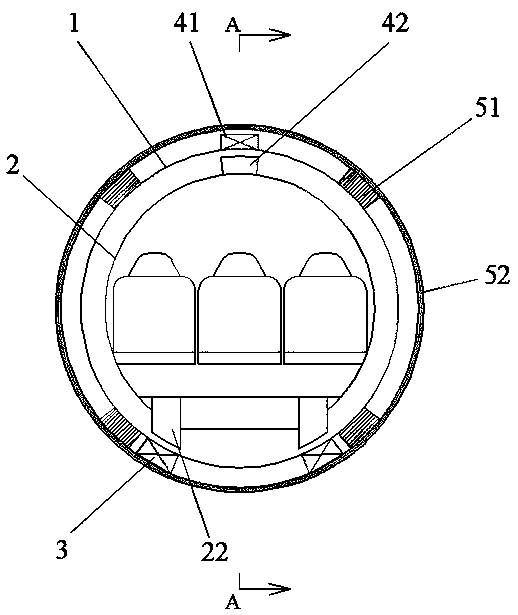

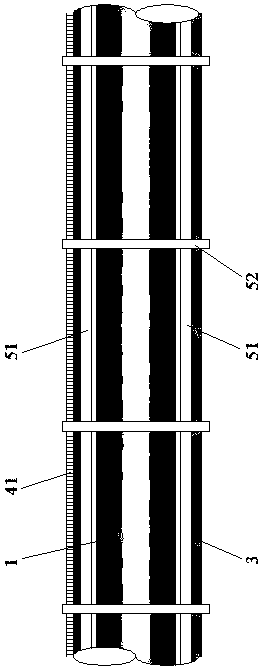

[0025] Such as figure 1 , figure 2 , image 3 As shown, a high-temperature superconducting vacuum pipeline transportation system with a circular pipeline section, an external suspension and drive system, and a smooth inner wall. It includes a pipeline 1, a vehicle 2, a permanent magnet track 3, a linear motor stator 41, a linear motor mover 42, a pipe rib 51, and a pipe collar 52.

[0026] Pipe 1 has a circular cross-section, smooth inner wall, and very thin pipe wall (less than 2mm). It is made of non-magnetic (does not affect the magnetic field, does not magnetize) light-weight high-strength materials such as stainless steel, aluminum alloy, titanium alloy, carbon nanotubes or graphene. Made of materials with good airtightness. In order to improve the strength of the pipe wall and ensure that the pipe 1 does not deform under the action of external pressure and dynamic load, the present invention provides the arrangement of pipe ribs 51 and pipe collars 52 . The pipe rib...

Embodiment approach 2

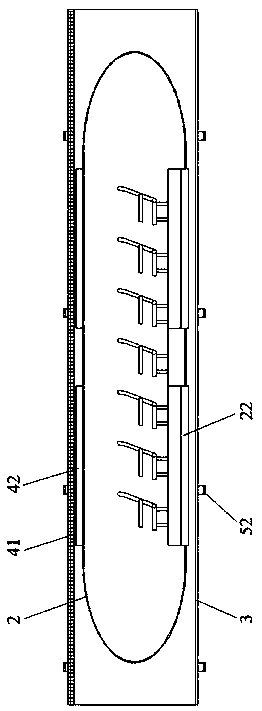

[0034] Such as Figure 4 As shown, a high temperature superconducting vacuum pipeline transportation system with an elliptical pipeline section, external suspension and drive system, and smooth inner wall. Its included content and setting are similar to the above-mentioned scheme one, which is characterized in that the section of the pipeline 1 is oval, the section of the vehicle 2 is oval, circular or rectangular, and the rectangular profile 6 formed by four support rollers 23 in the parallel plane of the section The length of the diagonal line 61 is greater than the length of the minor axis 7 of the elliptical duct 1, such as Figure 5 As shown, in order to prevent the vehicle from rotating and rolling in the pipeline 1 when the suspension system fails.

[0035] In a word, the solution provided by the present invention can effectively reduce the construction difficulty of vacuum pipeline transportation, facilitate inspection and maintenance, and significantly reduce the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com