A kind of anti-delamination solid brick and its preparation method

A solid brick and anti-delamination technology, applied in the field of building materials, can solve the problems of easy peeling of coatings, layering of hollow bricks, and affecting the quality of walls, so as to avoid layering and delamination, prevent layering and delamination, and avoid The effect of layering or delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

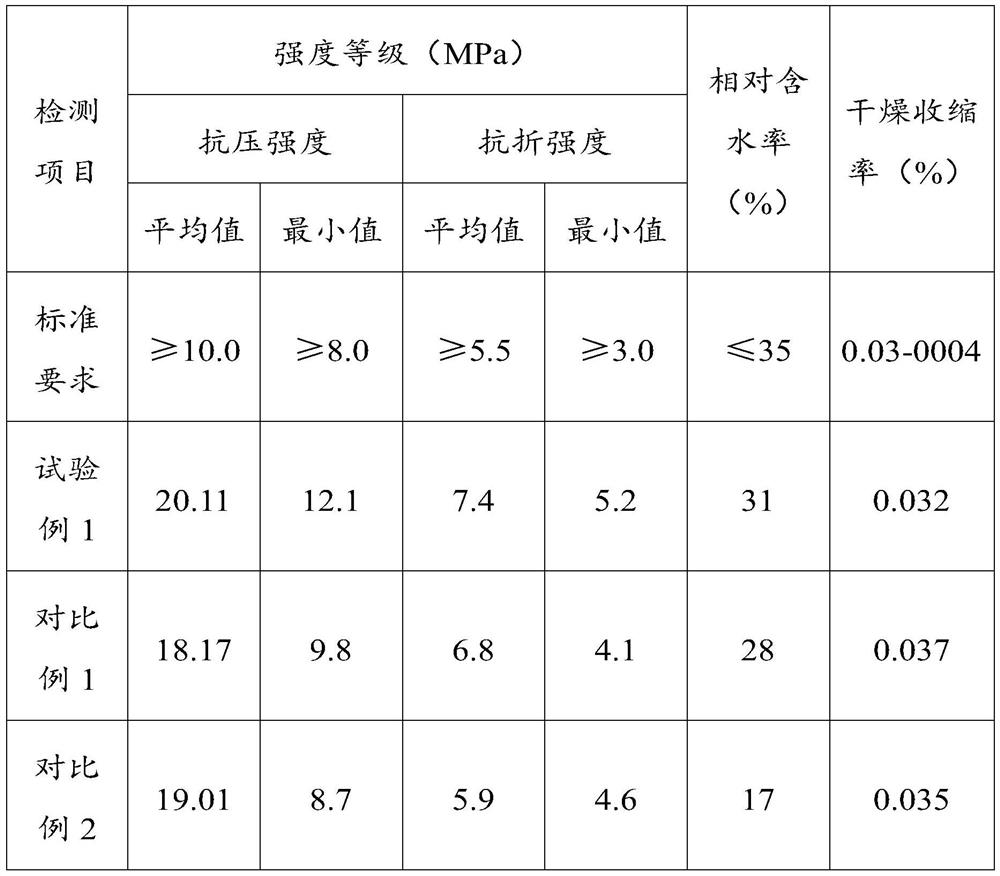

Examples

preparation example Construction

[0020] In addition, the present embodiment also provides a method for preparing a delamination-proof solid brick, which includes the following steps:

[0021] S1: forming a blank.

[0022] After mixing 30-40 parts of aggregate particles, 20-30 parts of fly ash and 2-3 parts of fiber, add 15-20 parts of cement, 15-20 parts of clay and 10-15 parts of pulp waste liquid, add water and mix well , mixed and milled, and extruded to form a billet.

[0023] Specifically, the aggregate particles include 40%-55% of the first particle, 20%-30% of the second particle and 25%-40% of the third particle in terms of mass percentage; the particle size of the first particle is greater than 2mm and less than or equal to 3mm ; The particle size of the second particle is greater than 0.1mm and less than or equal to 2mm; The particle size of the third particle is less than or equal to 0.1mm; After uniform, add the third particle evenly, then add fly ash and fiber, mix evenly.

[0024] S2: A coati...

Embodiment 1

[0036] This embodiment provides a delamination-proof solid brick.

[0037] The raw materials include: 15 parts of cement, 15 parts of clay, 30 parts of aggregate particles, 30 parts of fly ash, 15 parts of pulp waste liquid, 2 parts of fiber, 2 parts of borosilicate glass powder, 0.5 parts of glaze powder 5 parts of boron carbide powder, 1 part of alumina fine powder, 2 parts of aluminum powder, 8 parts of hydroxyethyl cellulose and 6 parts of water glass (the mass ratio of the first mixture and the second mixture is 10.5:14).

[0038] Among them, the aggregate particles include 40% of the first particle, 30% of the second particle and 30% of the third particle in terms of mass percentage; the particle size of the first particle is greater than 2mm and less than or equal to 3mm; the particle size of the second particle is greater than 0.1 mm and less than or equal to 2mm; the particle size of the third particle is less than or equal to 0.1mm.

[0039] Its preparation method i...

Embodiment 2

[0045] This embodiment provides a delamination-proof solid brick.

[0046] The raw materials include: 20 parts of cement, 20 parts of clay, 40 parts of aggregate particles, 20 parts of fly ash, 10 parts of pulp waste liquid, 3 parts of fiber, 3 parts of borosilicate glass powder, and 1 part of glaze powder. 3 parts, 3 parts of boron carbide powder, 1 part of alumina fine powder, 2 parts of aluminum powder, 8 parts of hydroxyethyl cellulose and 5 parts of water glass (the mass ratio of the first mixture and the second mixture is 10:13).

[0047] Wherein, the aggregate particles include 55% of the first particles, 20% of the second particles and 25% of the third particles in terms of mass percentage.

[0048] Its preparation method includes:

[0049] S1: First mix the first granule and the second granule, then add the third granule evenly, then add fly ash and fiber, mix evenly. Add cement, clay and pulp waste liquid, add water to mix evenly, carry out mixing and milling, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com