Anti-blue-ray printing ink, display device and manufacturing method of display device

A display device and anti-blue light technology, which is applied to inks, identification devices, instruments, etc., can solve problems such as aggravating blue light hazard, and achieve the effect of reducing blue light hazard, ensuring consistency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

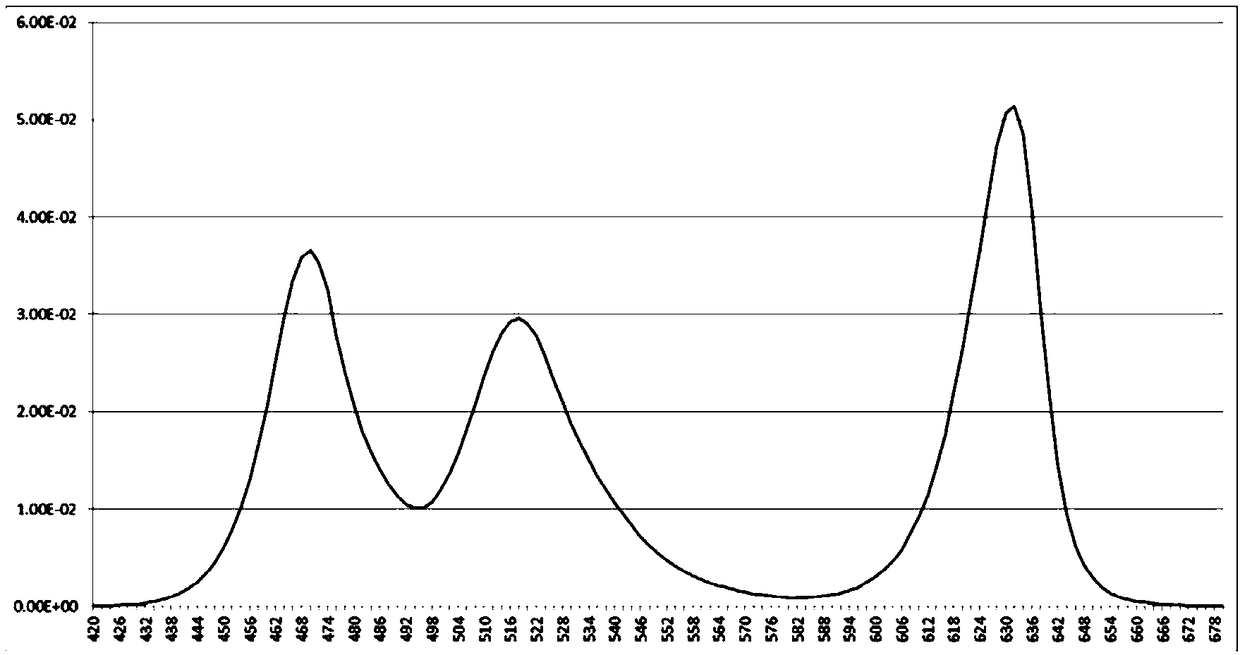

[0029] The inventors have found that the existing color displays generally obtain color images through the red, green and blue primary color control technology, and the wavelength of the luminous spectrum is generally within the visible light range of 380-780nm. Although for different types of displays, the spectral power distribution will vary. There are differences, but blue light components are generally relatively prominent (such as figure 1 shown). At present, for the existing LED (Light Emitting Diode, light emitting diode) display screen, the following methods are mainly used for anti-blue light treatment, which are specifically as follows.

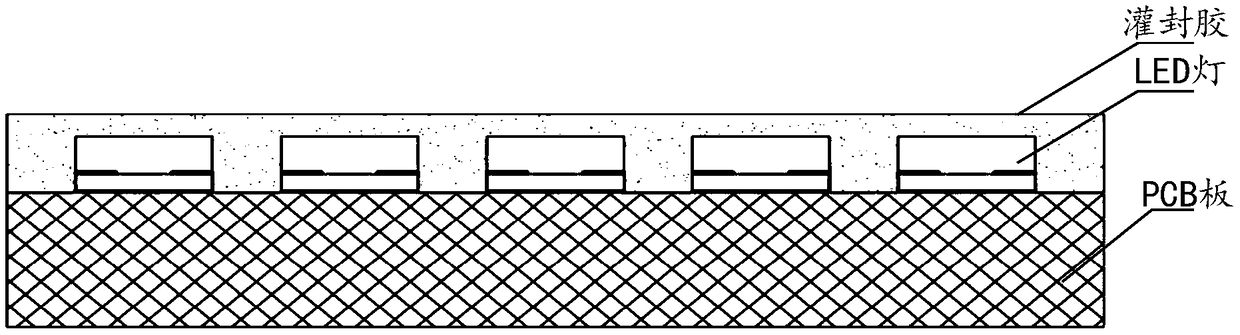

[0030] (1) When encapsulating LED lamps, directly add blue light suppression materials to the encapsulation adhesive. This method is the most convenient for downstream LED display manufacturers, who can directly use the corresponding LED lamps. However, for packaging manufacturers, due to the Problems such as classification of LED...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com