Special adhesive for ABS pressure-bearing equipment and preparation method of adhesive

A pressure-bearing equipment and adhesive technology, applied in the direction of adhesive types, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that ordinary adhesives cannot meet the requirements of ABS pressure-bearing strength Good bonding effect and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

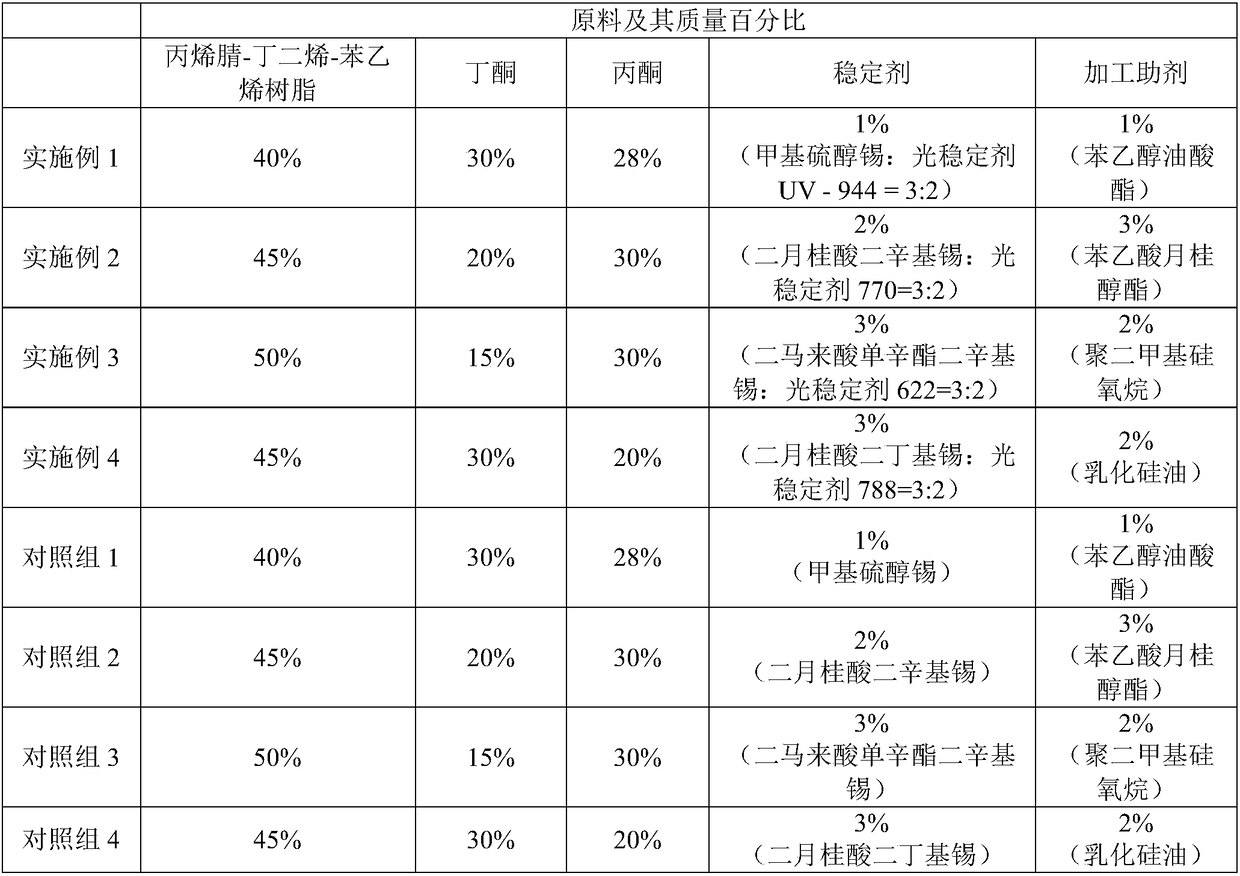

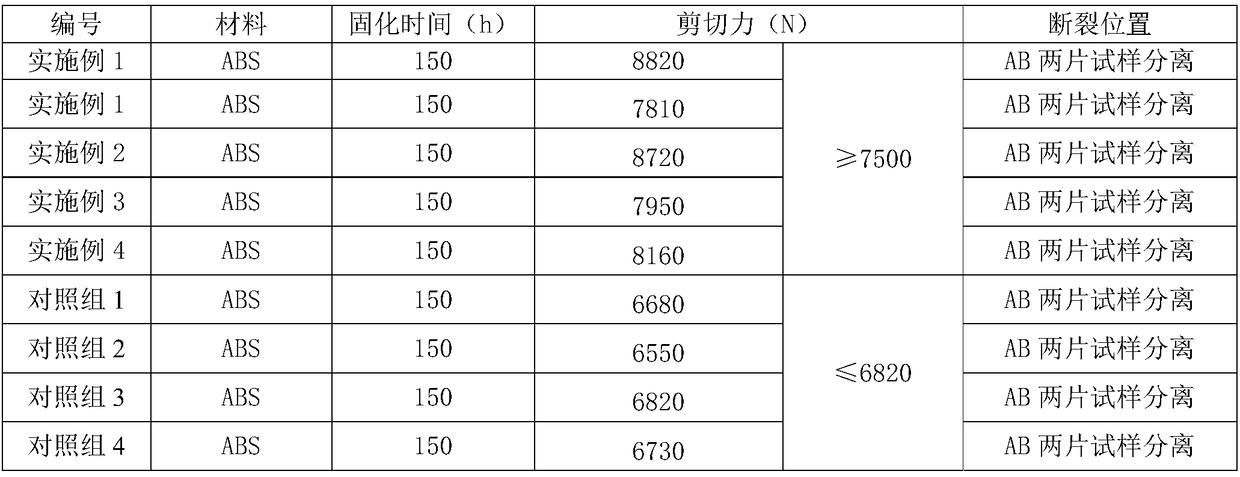

[0017] The raw materials used in the preparation of the special adhesive for ABS pressure-bearing equipment include: acrylonitrile-butadiene-styrene resin, butanone, acetone, stabilizer and processing aid. Among them, the stabilizers include heat stabilizers and light stabilizers. The heat stabilizers can be selected from organotin stabilizers such as methyl mercaptide, dioctyltin dilaurate, monooctyl dimalate, dibutyltin dilaurate, etc. One or more of them, light stabilizer can choose light stabilizer UV-944, light stabilizer 770 [bis (2,2,6,6-tetramethyl-4-piperidinyl) sebacate], Light stabilizer 622 [polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1-piperidine ethanol) ester], light stabilizer 788, light stabilizer 783 and other hindered amine stabilizers one or more of. Processing aids can be selected from phenylethyl alcohol oleate, lauryl phenylacetate, polydimethylsiloxane, emulsified silicone oil, high-carbon alcohol fatty acid ester complex, polyoxyethylene polyoxyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com