High-strength resin plugging agent as well as preparation method and application of high-strength resin plugging agent

A high-strength, resin-based technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult post-processing, complicated on-site construction, poor pumpability, etc., achieve convenient post-processing, meet on-site construction, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

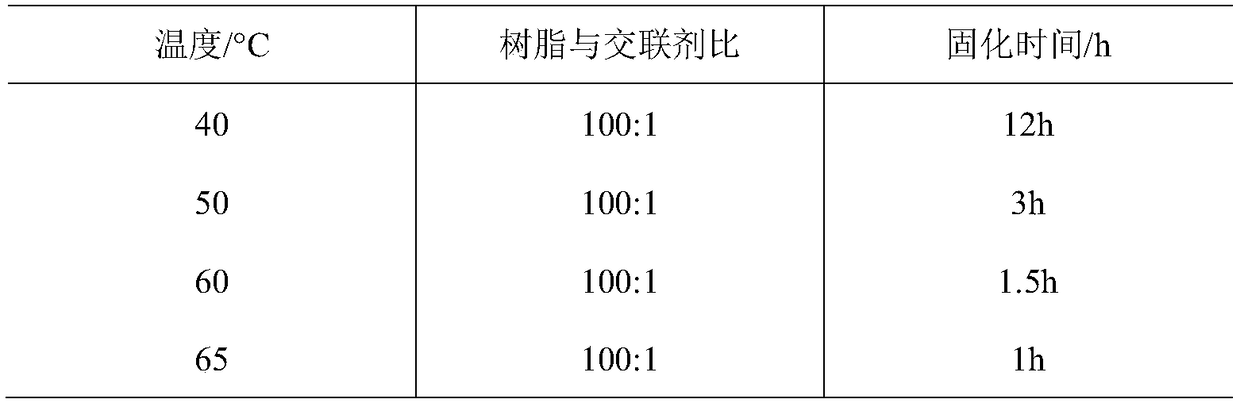

Method used

Image

Examples

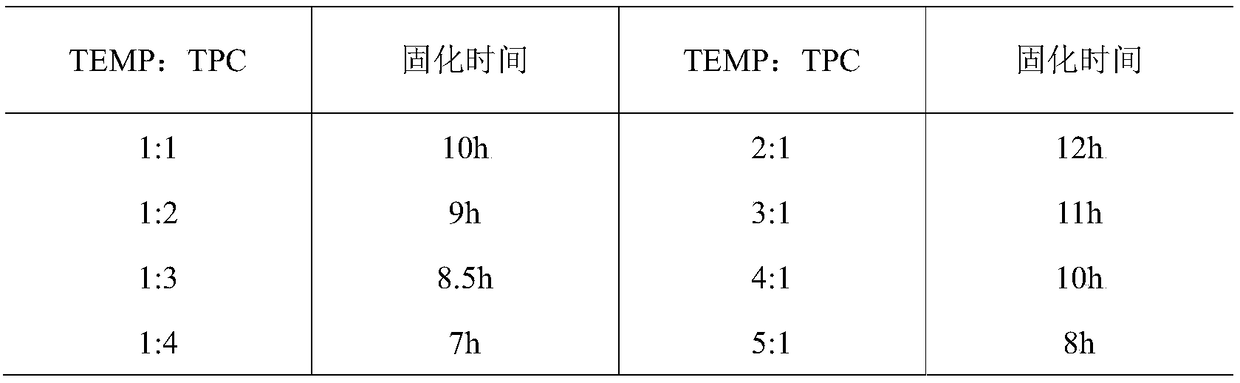

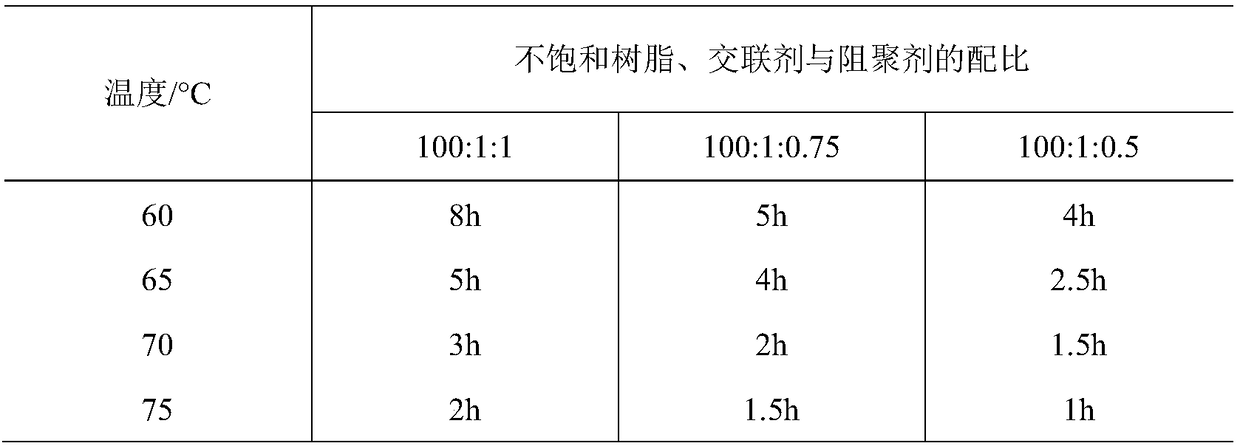

Embodiment 1

[0052] Add 100g of unsaturated resin, 1g of methyl ethyl ketone peroxide, 1g of polymerization inhibitor (TEMP:TPC=2:1), 1g of vinylpyrrolidone into the beaker, stir well, make it fully mixed, then add 5g of microsilica powder, stir well , to obtain the unsaturated resin plugging agent of the present invention into a gel solution. Place it in a sample bottle, seal it, and place it in a constant temperature water bath at 60°C to observe that the gelation time is 8 hours, the volume shrinkage rate is less than 1%, and it has good adhesion.

[0053] Inspection of blocking ability:

[0054] The plugging ability of the resin provided in this example was examined. The specific experimental process is as follows: two sand-filling tubes with an inner diameter of 2.5 cm and a length of 20 cm are filled with quartz sand to obtain high and low permeability simulated cores, which are recorded as 1# and 2#, and the original permeability is obtained after water flooding until the pressure is...

Embodiment 2

[0058] Add 100g of unsaturated resin, 0.5g of methyl ethyl ketone peroxide, 1g of polymerization inhibitor (TEMP:TPC=2:1), 1g of vinylpyrrolidone into the beaker, stir well, make it fully mixed, then add 5g of microsilica powder, stir Evenly, the unsaturated resin plugging agent of the present invention can be obtained. Place it in a sample bottle, seal it, and place it in a constant temperature water bath at 60°C to observe that the gelation time is 12 hours, the volume shrinkage rate is less than 1%, and it has good adhesion.

[0059] Inspection of blocking ability:

[0060] The plugging ability of the resin provided in this example was examined. The specific experimental process is as follows: two sand-filling tubes with an inner diameter of 2.5 cm and a length of 20 cm are filled with quartz sand to obtain high and low permeability simulated cores, which are denoted as 3# and 4#, and the original permeability is obtained after water flooding until the pressure is stable ...

Embodiment 3

[0064] Add 100g of unsaturated resin, 0.5g of methyl ethyl ketone peroxide, 2g of polymerization inhibitor (TEMP:TPC=2:1), 1g of vinylpyrrolidone into the beaker, stir well, make it fully mixed, then add 5g of microsilica powder, stir Evenly, the unsaturated resin plugging agent of the present invention can be obtained. Place it in a sample bottle, seal it, and place it in a constant temperature water bath at 60°C to observe that the gelation time is 20 hours, the volume shrinkage rate is less than 1%, and it has good adhesion.

[0065] Inspection of blocking ability:

[0066] The plugging ability of the resin provided in this example was examined. The specific experimental process is as follows: two sand-filling tubes with an inner diameter of 2.5 cm and a length of 20 cm are filled with quartz sand to produce high and low permeability simulated cores, which are recorded as 5# and 6#, and the original permeability is obtained after water flooding until the pressure is stable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com