Waterproof structure for pipeline penetrating through underwater outer wall

A waterproof structure and pipeline technology, applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of affecting project quality, difficult to cure water leakage, high maintenance costs, and achieve stable structure, long service life and impact resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with specific embodiments,

[0019] The embodiment takes the Chaohe Pumping Station Project of the Huancheng Ecological Water Circulation Pumping Station Project in Zhengzhou as an example.

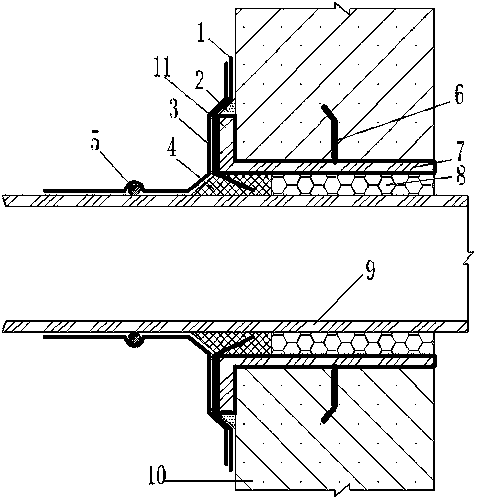

[0020] The diameter of the through-wall pipe 9 is 2000mm, the perforation diameter of the water-blocking wall is 2200mm, the outer diameter of the casing 7 is 2200mm, the inner diameter is 2100mm, the gap between the casing 7 and the through-wall pipe 9 is 100mm, and the thickness of the water-blocking wall 10 is 550mm;

[0021] First, a hole is made on the water blocking wall 10 to form a perforation for the through-wall pipe to pass through, and a water-stop steel plate 6 is arranged around the wall-penetrating pipe in the middle position of the water-blocking wall 10, and then a casing is inserted into the wall-penetrating pipe 9 to pass through. The gap between the casings 7 and the 2\3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com