Real-time calculation method for steam turbine exhaust enthalpy based on least squares support vector machine

A support vector machine and least squares technology, applied in computing, computer parts, data processing applications, etc., can solve problems such as overfitting, and achieve the effect of convenient and direct calling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

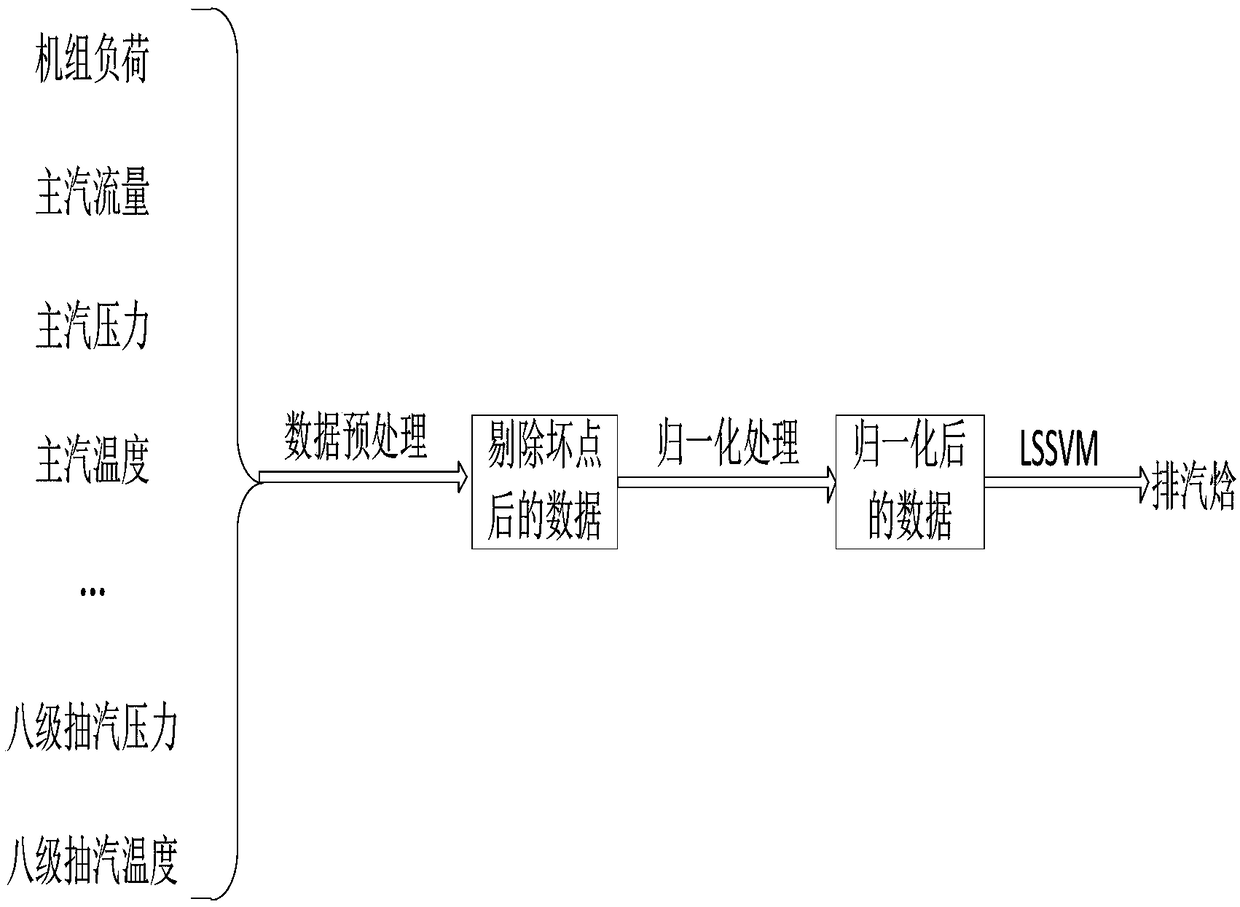

[0043] like figure 1 As shown, the present invention provides a method for real-time calculation of steam turbine exhaust enthalpy based on least squares support vector machine, comprising the following steps:

[0044] 1) Collect historical steady-state data

[0045] In the production process database system of the power plant, historical data (unit load, main steam flow, pressure and temperature, pressure and temperature after regulating stage, inlet steam pressure and temperature of intermediate pressure cylinder, etc.) are extracted from the historical data of steam turbine under normal operation and full load Parameters, high pressure cylinder exhaust pressure and temperature, low pressure cylinder exhaust pressure and temperature and other exhaust steam parameters, steam turbine eight-stage regenerative system extraction steam extraction pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com