FeBC soft magnetic amorphous alloy with few components, low cost and high saturation magnetic induction strength and preparation process thereof

A technology of amorphous alloy and preparation process, which is applied in the field of FeBC soft magnetic amorphous alloy and its preparation process, can solve the problems of large number of components, control of unfavorable components, etc., and achieve simplified smelting process, good toughness and soft magnetic properties , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

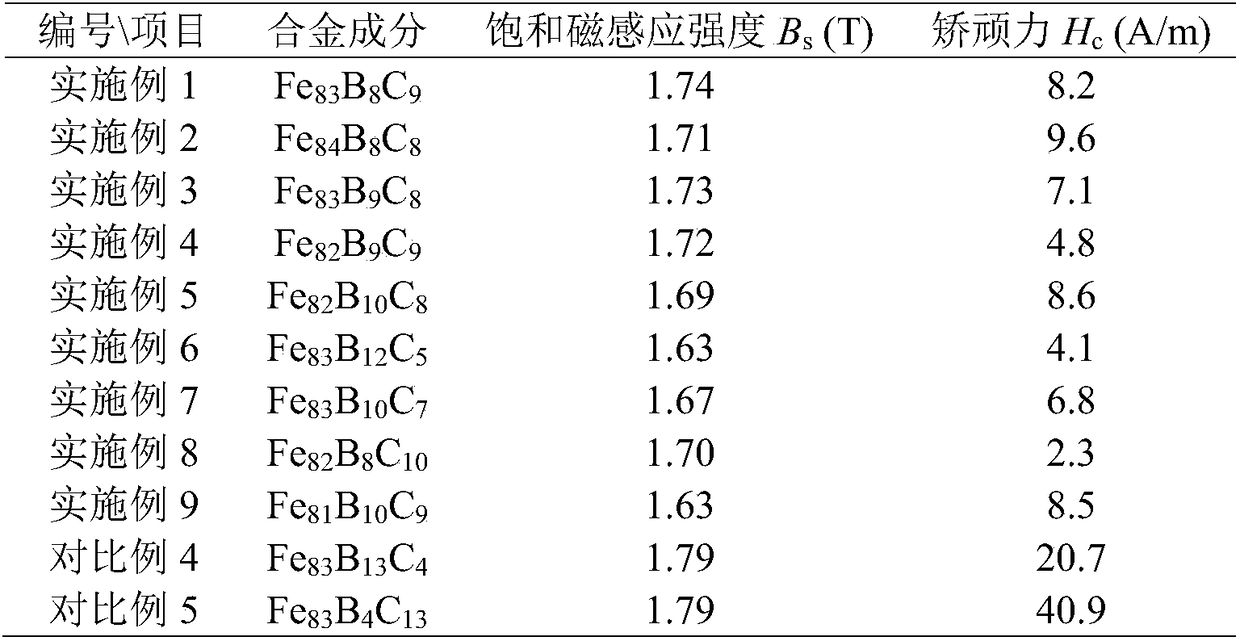

[0025] An FeBC soft magnetic amorphous alloy is composed of iron, boron and carbon elements. The atomic percentages of the elements in the alloy are as follows: 8% boron, 9% carbon, and 83% iron.

[0026] The preparation steps are as follows:

[0027] (1) The raw materials are pure iron (99.9%), industrial grade iron-carbon alloy (carbon mass percentage is 4.2%), industrial grade iron-boron master alloy (B mass percentage is 18.9%);

[0028] Use a balance to weigh the raw materials according to the atomic percentages of Fe83%, B8%, and C9%, which are Fe: 5.59g, Fe-C master alloy: 7.99g, Fe-B master alloy: 1.42g;

[0029] (2) Put the raw materials into the glass tube in the vacuum induction melting furnace, and use a mechanical pump and a molecular pump to evacuate to 2×10 - 3 Pa, filled with high-purity argon for arc smelting; after smelting, take it out and smash it to check whether there are unmelted raw materials, and if there are unmelted materials, carry out the second ...

Embodiment 2

[0034] An FeBC soft magnetic amorphous alloy is composed of iron, boron and carbon elements, and the atomic percentages of each element in the alloy are as follows: 8% boron, 8% carbon, and 84% iron.

[0035] The preparation steps are as follows:

[0036] (1) The raw materials are pure iron (99.9%), industrial-grade iron-carbon master alloy (the mass percentage of carbon is 4.16%), and industrial-grade iron-boron master alloy (the mass percentage of B is 18.87%);

[0037] Use a balance to weigh the raw materials according to the atomic percentages of Fe82%, B9%, and C9%, which are Fe: 6.45g, Fe-C master alloy: 7.12g, Fe-B master alloy: 1.42g;

[0038] (2) Put the raw materials into the glass tube in the vacuum induction melting furnace, and use a mechanical pump and a molecular pump to evacuate to 2×10 - 3 Pa, filled with high-purity argon for arc smelting; after smelting, take it out and smash it to check whether there are unmelted raw materials, and if there are unmelted m...

Embodiment 3

[0043] A FeBC soft magnetic amorphous alloy is composed of iron, boron and carbon elements, and the atomic percentages of each element in the alloy are as follows: boron 9%, carbon 8%, iron 83%.

[0044] Preparation step is the same as embodiment 1, the obtained Fe 83 B 9 C 8 Amorphous ribbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com