Lead-acid storage battery or battery pack

A technology of lead-acid batteries and battery packs, which is applied in the direction of lead-acid batteries, lead-acid battery construction, capacitor collector combination, etc., and can solve problems such as short service life, low utilization rate of active materials, and large electrode specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

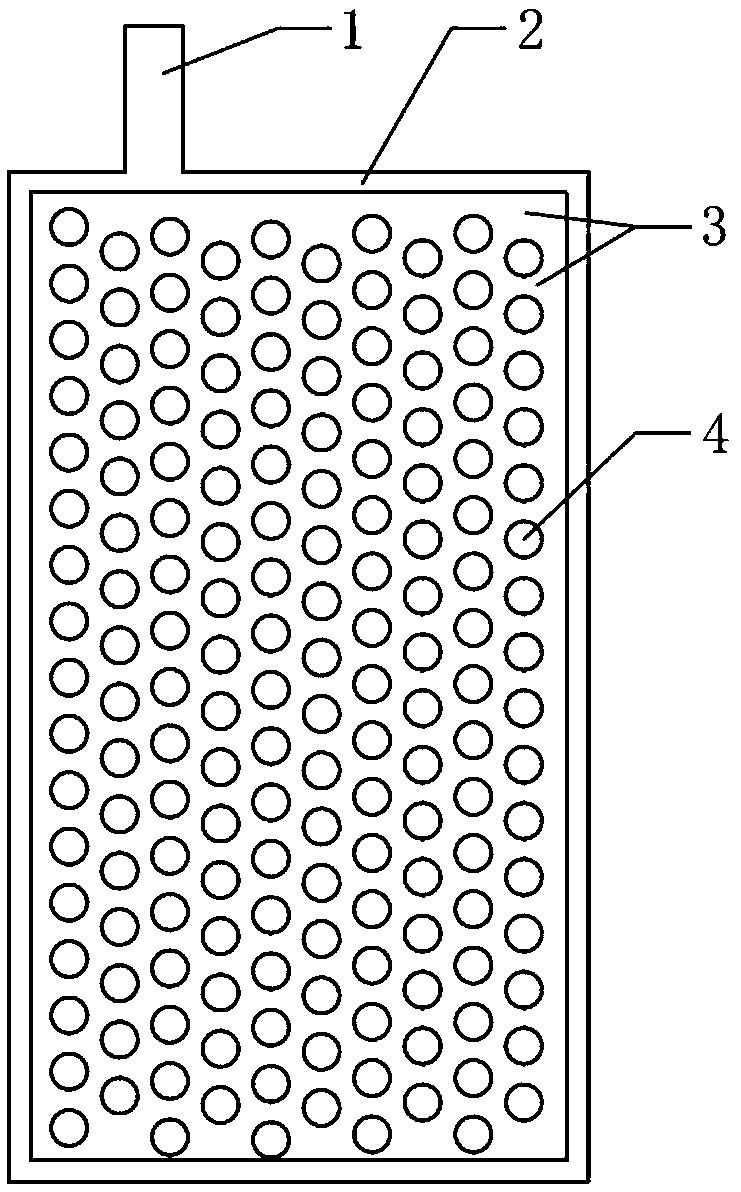

[0095] Present embodiment valve-regulated sealed lead-acid accumulator or battery pack (VRLAB), its positive pole, negative pole have identical lead paste and lead paste formula each other before electric formation, and the formula of this lead paste is: 100kg ball-milled lead powder, 0.05kg short fiber, 0.18kg lignin, 0.30kg acetylene black, 0.60kg barium sulfate, 0.06kg silicon dioxide, 8.25kg water, 8.7kg sulfuric acid aqueous solution (45Wt.%), the present embodiment lead-acid accumulator or battery pack The rated voltage is U volts and the rated capacity is C 2 (2h rate, 25℃), C 5 (5h rate, 25℃) or C 20 (20h rate, 25°C), where U=2, 6, 12, 24, 36, 48, 60 or 72, C 2 = 6.5Ah, 12Ah, 14Ah, 16Ah, 20Ah, 24Ah, 30Ah or 32Ah, or, C 5 = 8.6Ah, 15.9Ah, 18.6Ah, 21.2Ah, 26.5Ah, 31.9Ah, 39.8Ah or 42.5Ah or, C 20 = 10.4Ah, 19.2Ah, 22.4Ah, 25.6Ah, 32Ah, 38.4Ah, 48Ah or 51.2Ah. The positive electrodes of the lead-acid storage battery or the battery pack of the present embodiment are e...

Embodiment 2

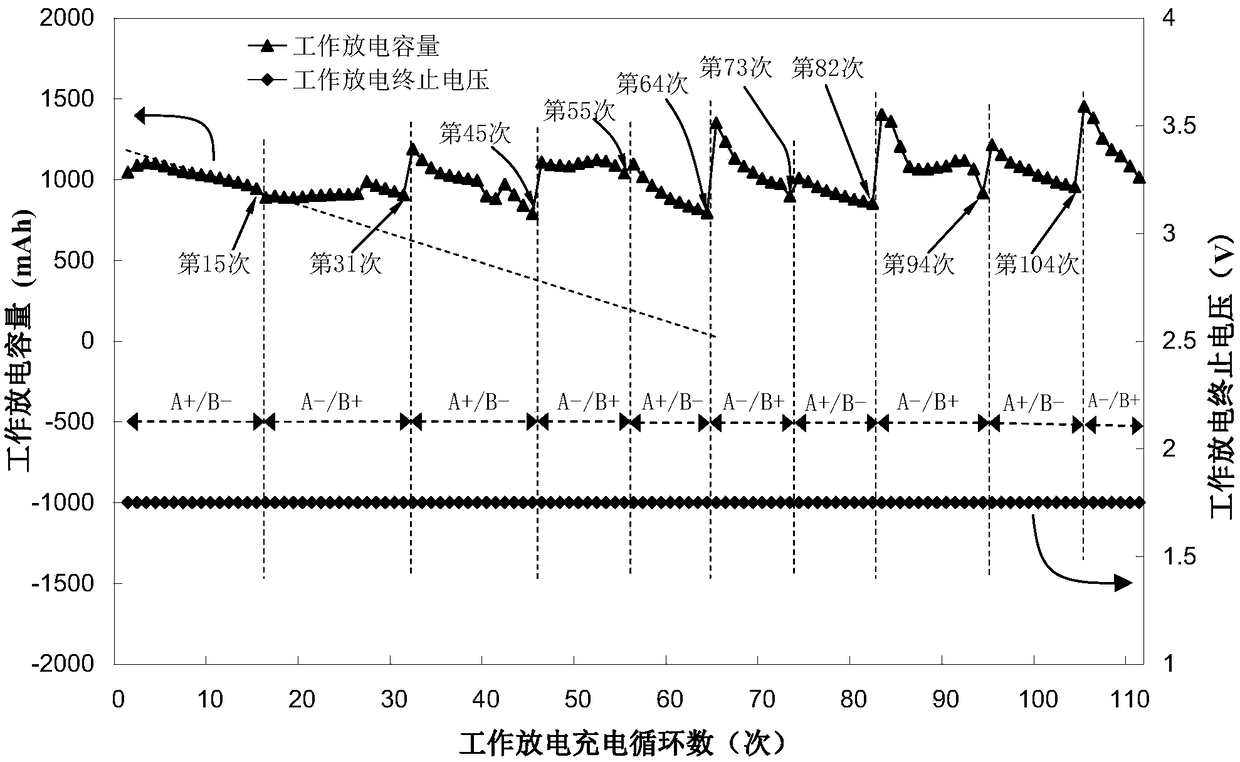

[0100]One of the embodiments of the lead-acid storage battery or battery pack in this embodiment is that the flat grid-type lead-acid storage battery in this embodiment has a rated voltage of 2V and includes a flat grid-type positive electrode and a flat grid-type negative electrode for convenience. Note that the two planar grid electrodes are respectively referred to as electrode A and electrode B, and there is a separator between the electrodes A and B, and the electrodes A and B are the same as each other or the same type of electrodes before the electrodes are formed, that is, , regardless of the manufacturing error produced when manufacturing the electrode, before the two electrodes are formed, all aspects of electrode manufacturing or composition, such as manufacturing process, material, electrode structure (such as electrode structure, shape, size, current collector , lead paste, lead paste formula, lead paste quality, etc.) and other aspects of electrode manufacturing o...

Embodiment 3

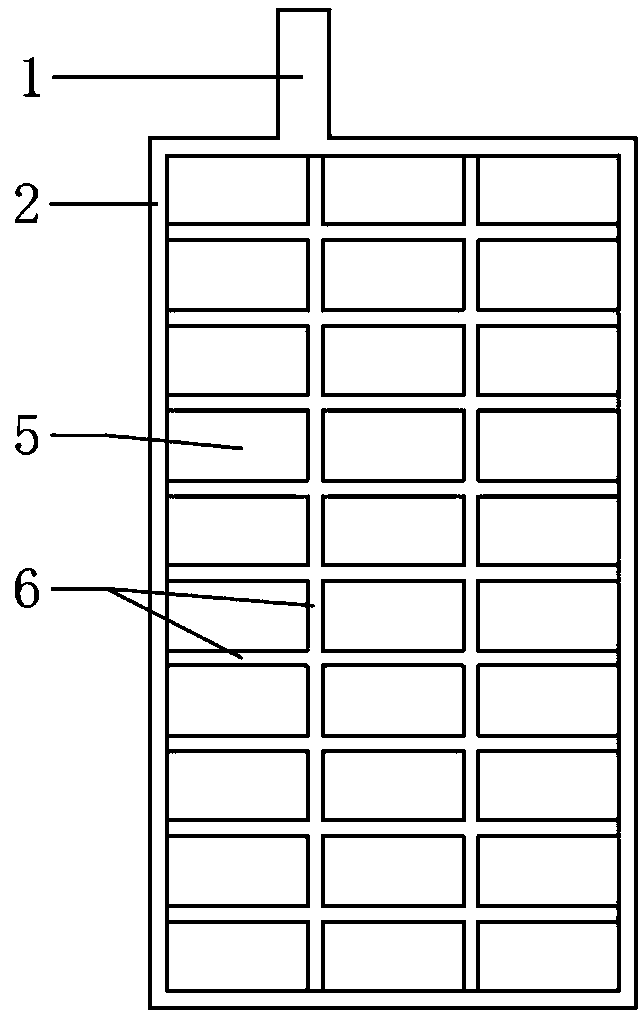

[0128] In the lead-acid storage battery or battery pack of this embodiment, the active material formula of the positive pole and the negative pole or the active material before the electric polarization are the same as each other, or / and, the positive pole and the negative pole are the same or the same as each other before the electric polarization A kind of electrode, that is, the positive electrode and the negative electrode, before the electrode is formed, without considering the manufacturing error, all aspects of electrode manufacturing or composition, such as manufacturing process, material, electrode structure (such as electrode structure, shape, Size, current collector, active material, active material formulation, active material quality, etc.) and other aspects of electrode fabrication or composition are the same.

[0129] In this embodiment, the lead-acid storage battery or battery pack has a positive pole and a negative pole of plane grid type, tubular type, bipolar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap