Water-cooled motor with adjustable coolant pressure

A coolant and water-cooled technology, applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of small heat dissipation area, high power density of drive motor, and increased system complexity, so as to improve utilization rate and reduce Effects of starting load, improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

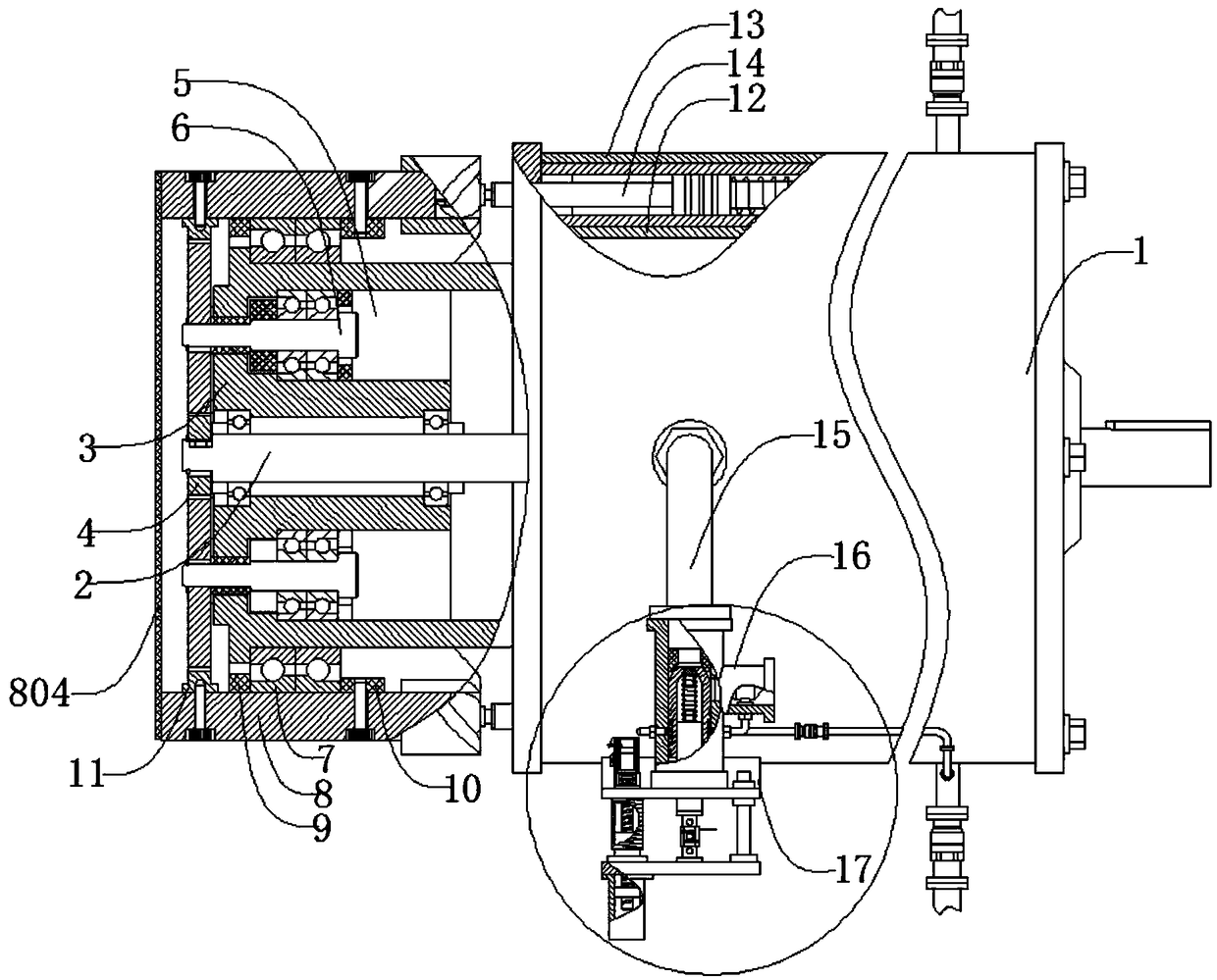

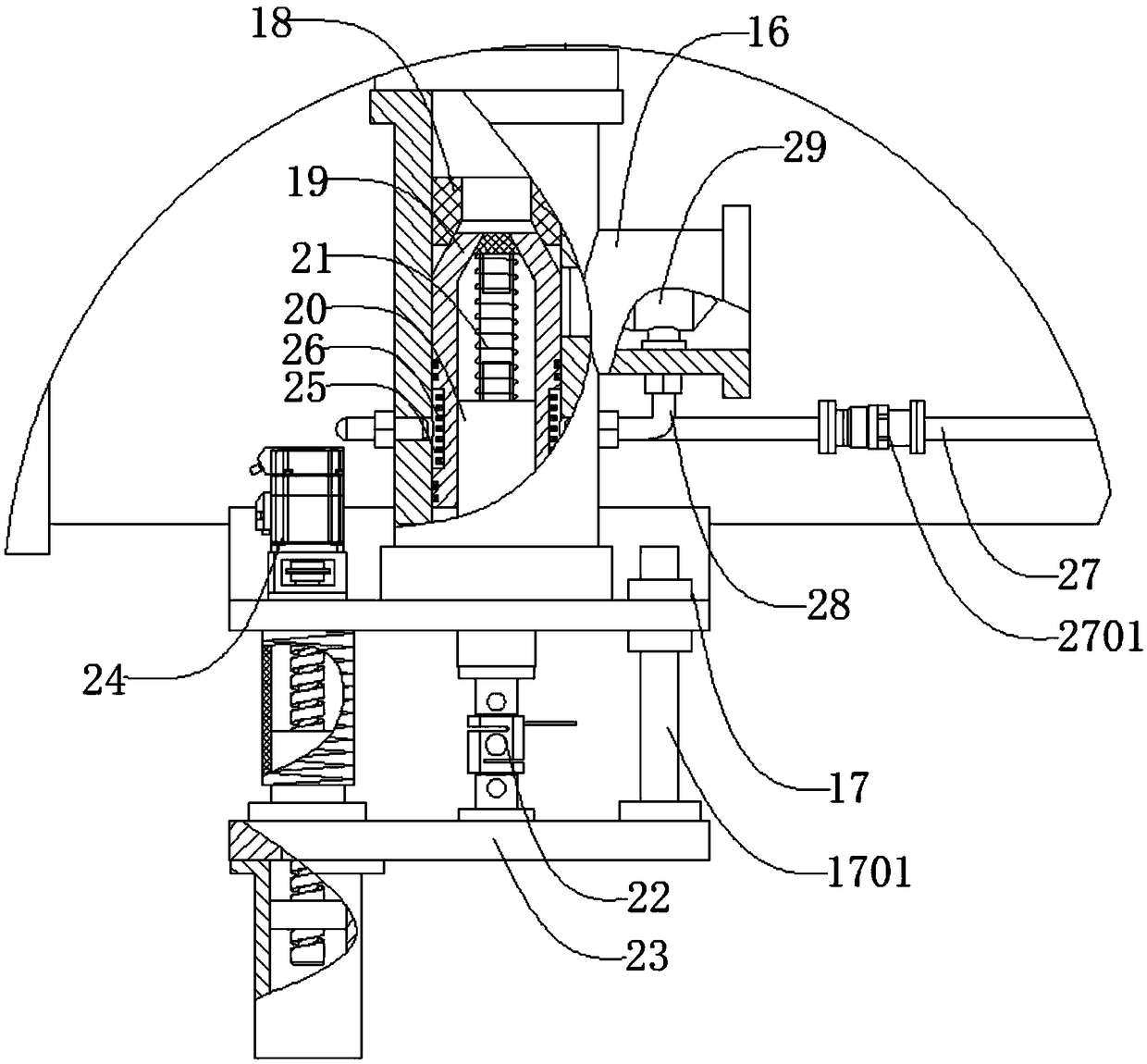

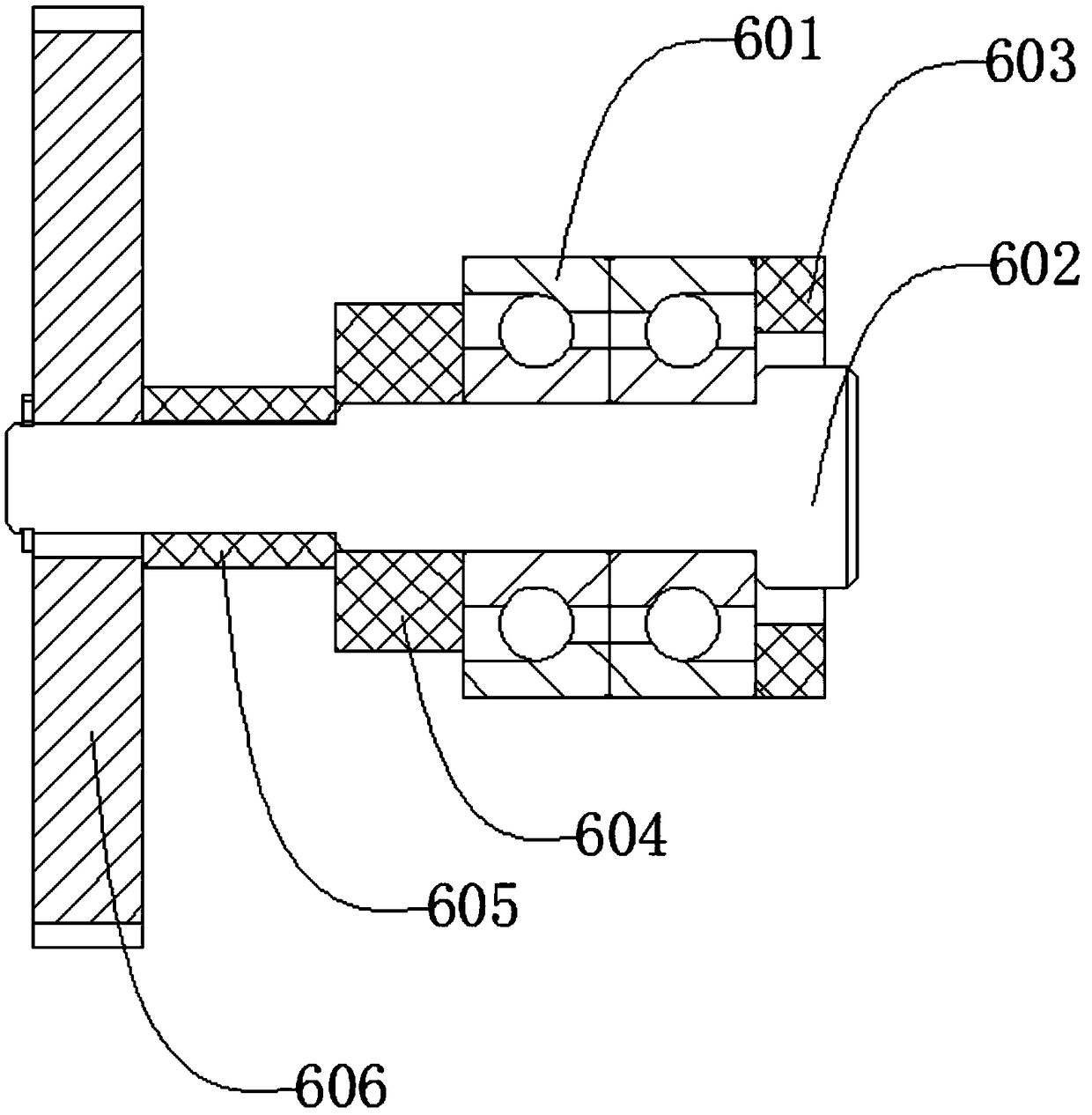

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8As shown, a water-cooled motor with adjustable coolant pressure includes a motor body 1 and a first rotating shaft 2 arranged on the motor body 1, and also includes a support 3, a first gear 4, and a number of Not less than 2 pieces of fixed groove 5, transition mechanism 6, first bearing 7, combined cam mechanism 8, outer block 9, inner block 10, ring gear 11, inner shell 12, outer shell 13, pumping mechanism 14, Outlet pipe 15, pipe body 16, bracket 17, throttle seat 18, sealing head 19, push rod 20, first spring 21, tension pressure sensor 22, bottom plate 23, servo drive mechanism 24, cooling ring groove 25, cooling fin Sheet 26, coolant inlet pipe 27, coolant outlet pipe 28, heat spreader 29, the support 3 is located on the left side of the motor body 1, the support 3 is connected to the motor body 1 by bolts, the The first gear 4 is located on the left side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com