Non-combustible reconstituted tobacco heated by oxidized graphene

A heat-not-burn and reconstituted tobacco leaf technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, can solve problems such as insufficient thermal conductivity, achieve excellent antibacterial performance, improve heating efficiency, and prolong storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

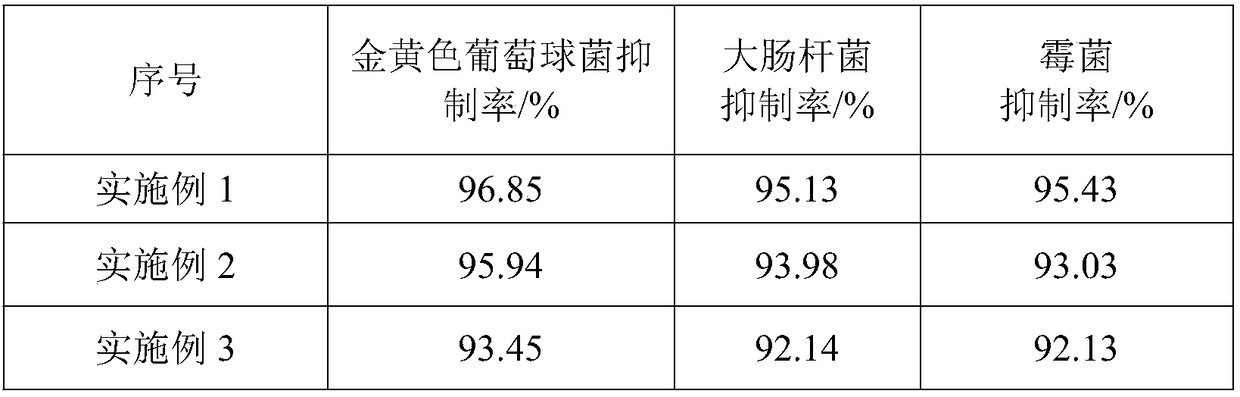

[0022] A graphene oxide heat-not-burn reconstituted tobacco leaf. The reconstituted tobacco leaf contains the raw materials in parts by weight shown in Table 1, wherein the auxiliary material is 5 parts of seaweed polysaccharide. See Table 1 for specific parts by weight.

[0023] Among them, A part of plant fiber, B part of tobacco raw material, C part of smoking agent, D part of graphene oxide, and E part of tobacco spice.

[0024] Table 1

[0025] serial number

A

B

C

D

E

Example 1

10

60

10

0.2

5

Example 2

20

60

10

0.2

5

Example 3

10

50

10

0.2

5

Example 4

10

60

20

0.2

5

Example 5

5

60

10

0.2

5

Example 6

10

40

10

0.2

5

Example 7

10

85

10

0.2

5

Example 8

10

60

5

0.2

5

Example 9

10

60

10

0.5

5

Example 10

10

60

10

0.2

1

Example 11

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com