Plate and pipe integrated optical fiber laser cutting machine based on PLC system

A fiber laser and cutting machine technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not being able to process plates and pipes at the same time, only processing plates, and only processing pipes, etc., to avoid Accidental personal injury, precise cutting accuracy, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

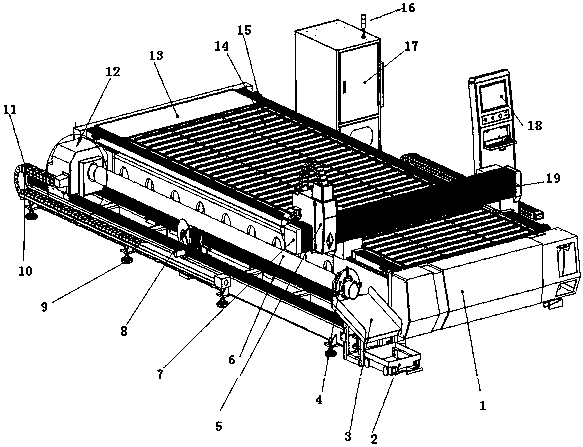

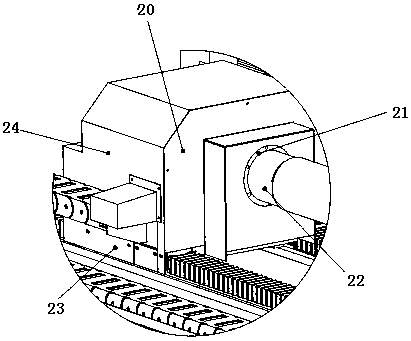

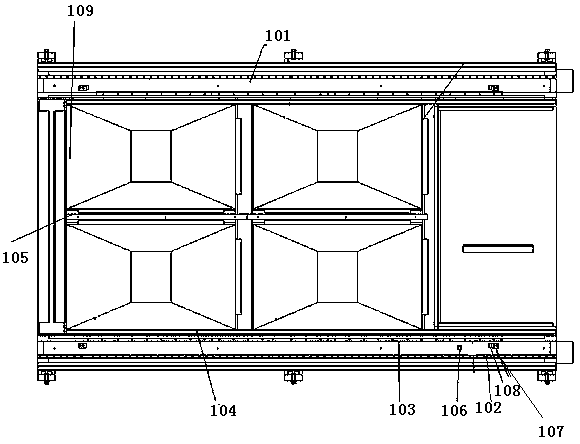

[0020] Example: such as figure 1 and figure 2 As shown, a plate-tube integrated fiber laser cutting machine based on the PLC system includes a machine tool 1 and a cutting workbench 14. A beam structure 19 is arranged horizontally above the cutting workbench 14. A laser cutting head 5 is arranged on the beam structure 19. The machine tool 1 is provided with a welded steel pipe frame 11, and one end of the welded steel pipe frame 11 is provided with an intersecting line drive system 12. The other end is provided with a chuck set as the front chuck 4, and the cutting steel pipe 6 prevents the welding steel pipe frame from 11, the middle position of welded steel pipe frame 11 is provided with adjustable variable diameter tugboat 8, is also provided with movable line towline 10 around welded steel pipe frame 11, also includes laser generation box 17, is set in laser generation box 17 There is a laser generator and an electronic controller, the laser generator is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com