Deburring machine for bamboo artificial board

A technology for deburring machines and wood-based panels, which is applied in the direction of manufacturing tools, machine tools suitable for grinding workpiece planes, and machine tools suitable for grinding workpiece edges, etc. It can solve the problems of narrow processing range, low processing efficiency, and poor burr handling, etc. problems, to achieve the effect of improving the processing accuracy and comprehensiveness, improving the quality of finished products, and widening the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0021] Example.

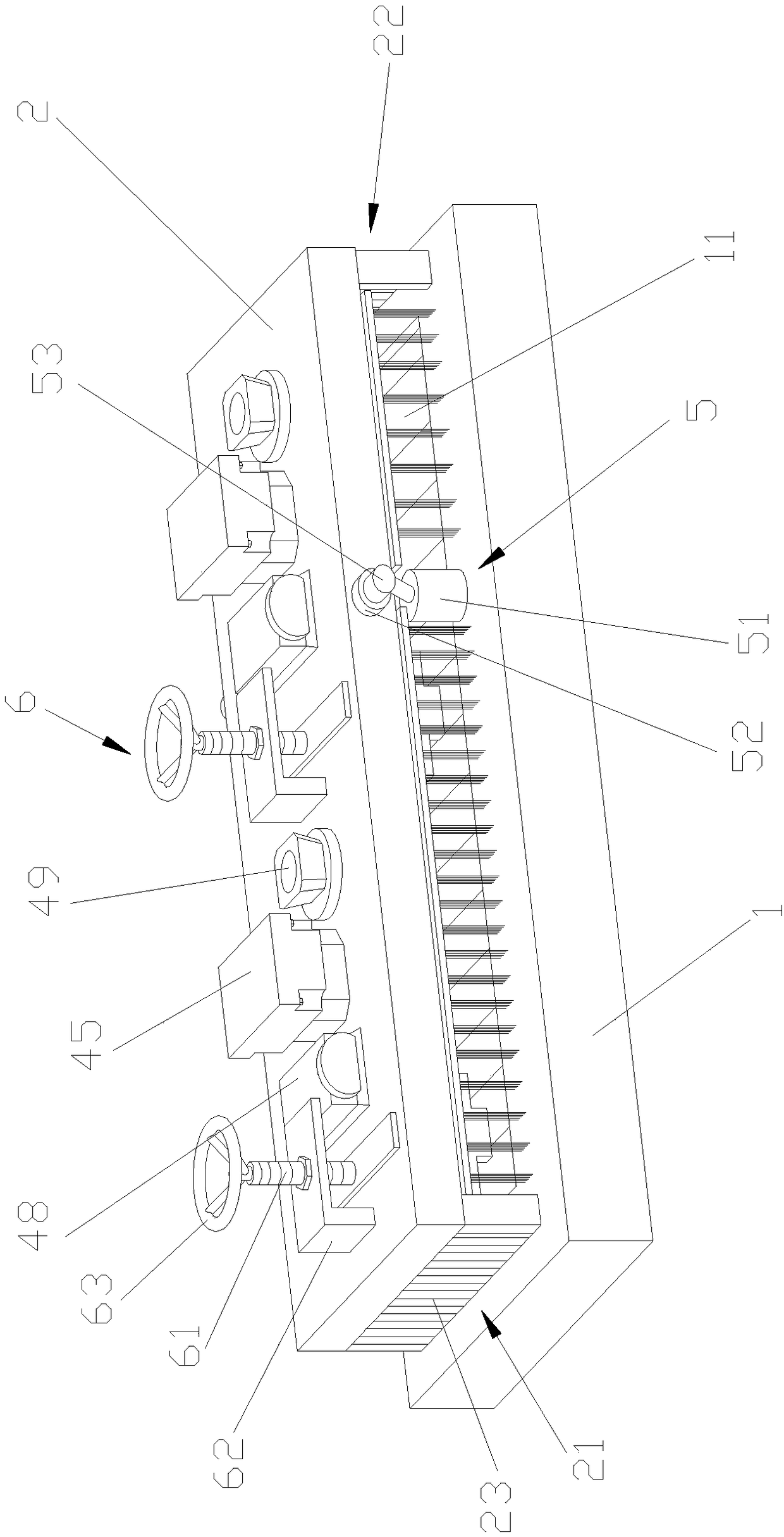

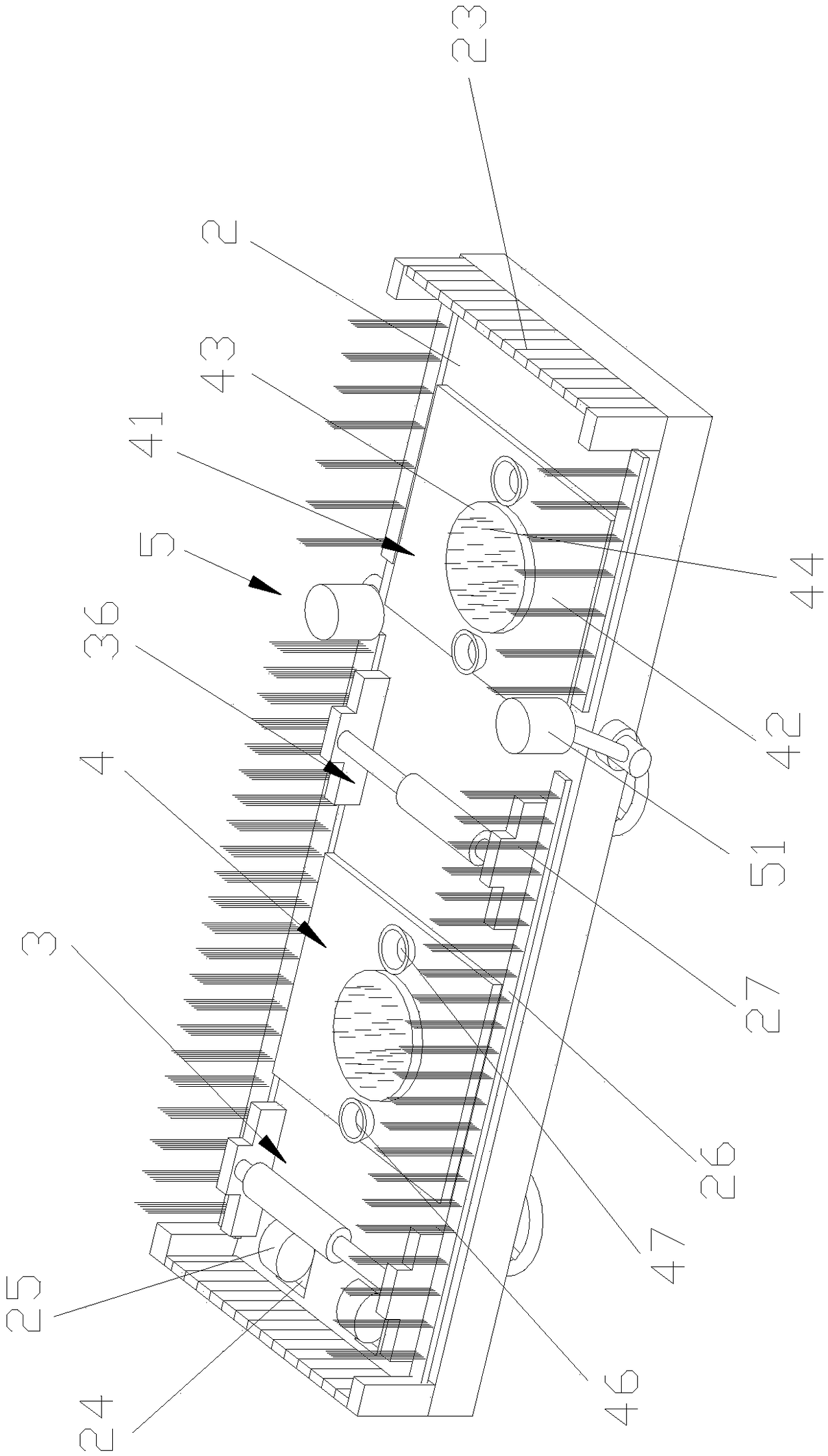

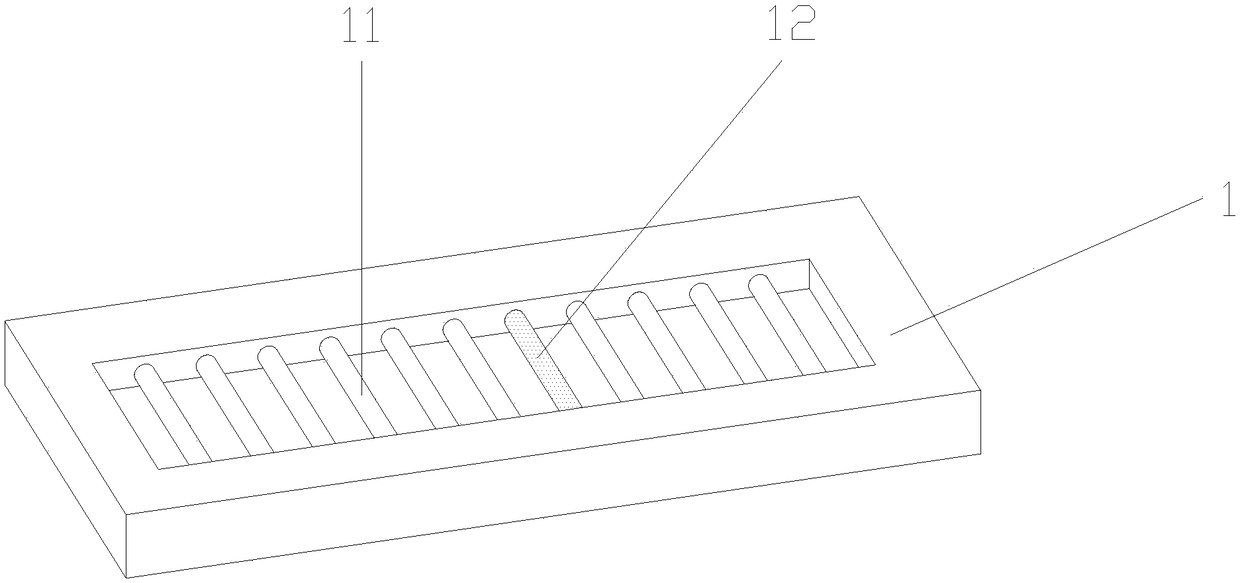

[0022] Such as figure 1 , figure 2 with image 3 Shown, a kind of deburring machine of bamboo wood-based panel comprises machine base 1, and the top surface of described machine base 1 is provided with transmission roller 11, and transmission roller 11 is connected with transmission motor by transmission chain, utilizes transmission motor to drive transmission roller 11 rotates, and one of the transmission rollers 11 is wrapped with a bottom frosted sheet 12, and a plurality of bottom frosted sheets 12 can also be set. The top of the base 1 is provided with a processing frame 2, and the processing frame 2 runs along the transmission roller 11. Conveying direction is provided with the first scrubbing device 3, the first cleaning device 4, the second scrubbing device 36, the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com