Gear-oil additive, gear lubricating oil, preparation method and application thereof

A technology of gear lubricating oil and additives, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., to achieve the effect of improving lubrication state, improving friction and wear performance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

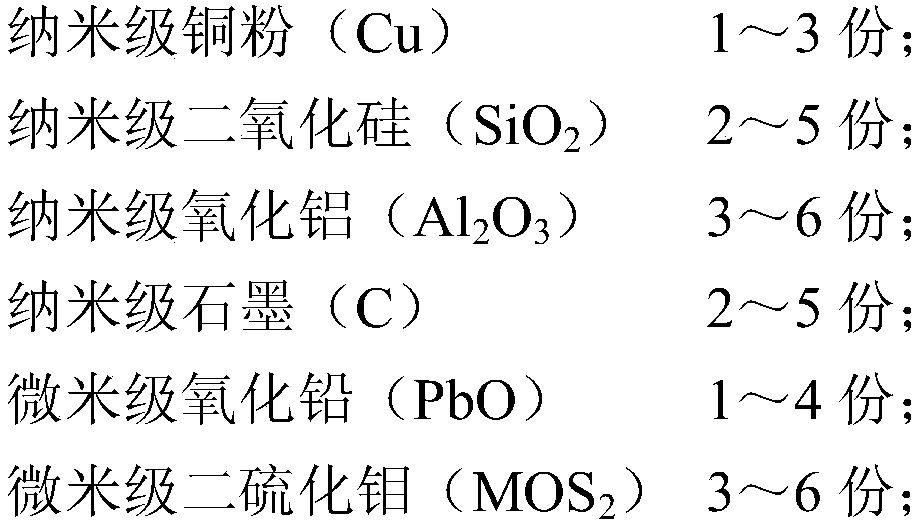

[0039] A gear oil additive comprising the following components in parts by mass:

[0040]

[0041] The preparation method of described gear oil additive, comprises the steps:

[0042] Each component of above-mentioned gear oil additive is mixed uniformly, obtains 19mg gear oil additive;

[0043] A kind of gear lubricating oil, comprises above-mentioned gear oil additive and SAE 85W-90 base lubricating oil;

[0044] The preparation method of described gear lubricating oil comprises the steps:

[0045] (1) Add 228mg of SAE 85W-90 base lubricating oil into a beaker, and then add the above-mentioned gear oil additive;

[0046] (2) Perform ultrasonic stirring for 40 minutes to obtain 247 mg of stable gear lubricating oil.

[0047] The gear lubricating oil prepared in this embodiment was used to inject oil to lubricate the gears under different operating conditions, and then detect the running noise, tooth surface roughness and tooth surface hardness of the gears, see the effe...

Embodiment 2

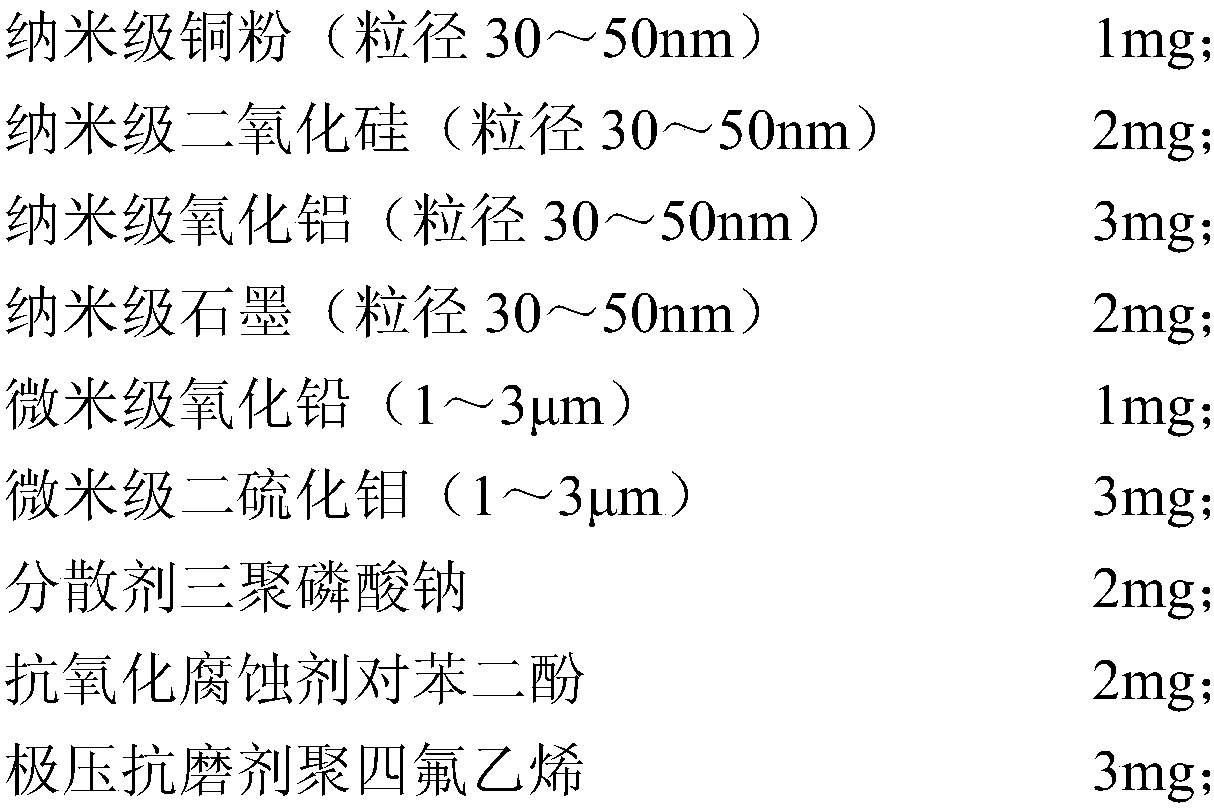

[0049] A gear oil additive comprising the following components in parts by mass:

[0050]

[0051] The preparation method of described gear oil additive, comprises the steps:

[0052] Each component of above-mentioned gear oil additive is mixed uniformly, obtains 34mg gear oil additive;

[0053] A kind of gear lubricating oil, comprises above-mentioned gear oil additive and SAE 85W-90 base lubricating oil;

[0054] The preparation method of described gear lubricating oil comprises the steps:

[0055] (1) Add 408mg of SAE 85W-90 base lubricating oil into a beaker, and then add the above-mentioned gear oil additive;

[0056] (2) Ultrasonic stirring was carried out for 40 minutes to obtain 442 mg of stable gear lubricating oil.

[0057] The gear lubricating oil prepared in this embodiment was used to inject oil to lubricate the gears under different operating conditions, and then detect the running noise, tooth surface roughness and tooth surface hardness of the gears, see ...

Embodiment 3

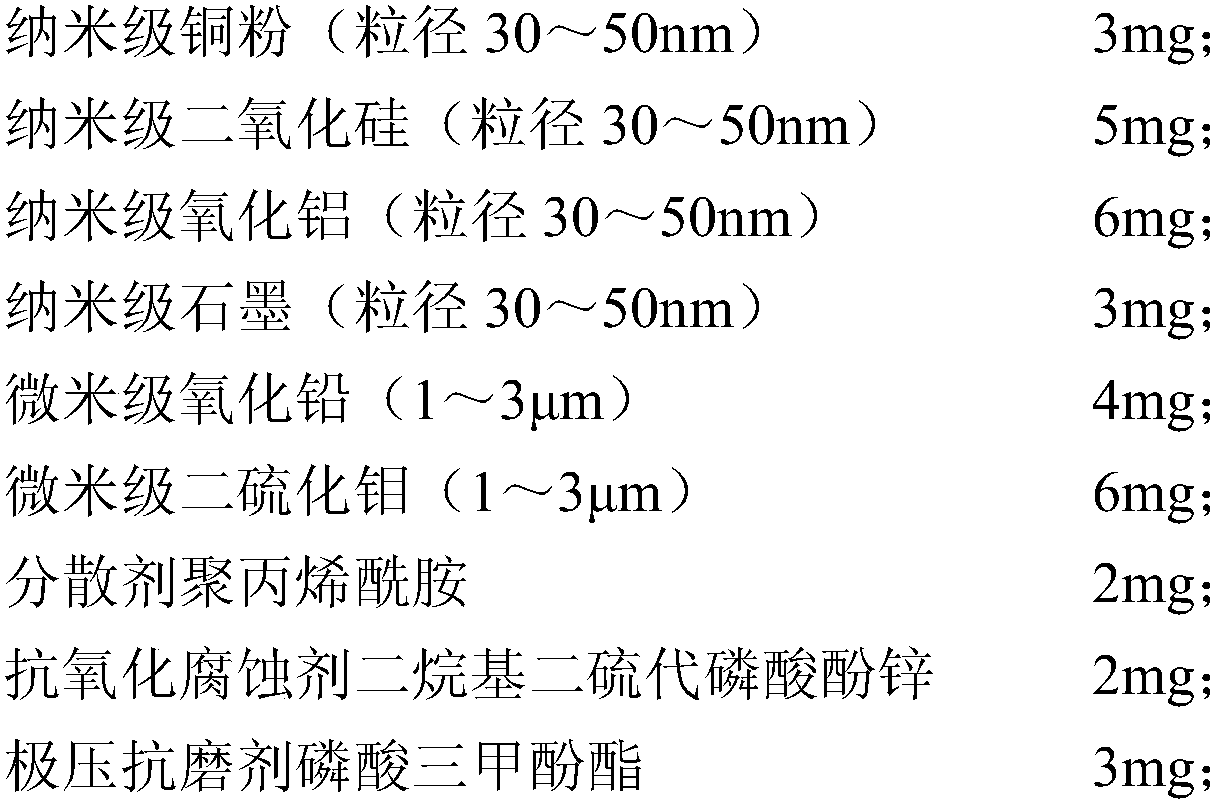

[0059] A gear oil additive comprising the following components in parts by mass:

[0060]

[0061] The preparation method of described gear oil additive, comprises the steps:

[0062] Each component of above-mentioned gear oil additive is mixed uniformly, obtains 26mg gear oil additive;

[0063] A kind of gear lubricating oil, comprises above-mentioned gear oil additive and SAE 85W-90 base lubricating oil;

[0064] The preparation method of described gear lubricating oil comprises the steps:

[0065] (1) Add 312mg of SAE 85W-90 base lubricating oil into a beaker, and then add the above-mentioned gear oil additive;

[0066] (2) Ultrasonic stirring was carried out for 40 minutes to finally form 338 mg of stable gear lubricating oil.

[0067] The gear lubricating oil prepared in this embodiment was used to inject oil to lubricate the gears under different operating conditions, and then detect the running noise, tooth surface roughness and tooth surface hardness of the gears, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com