Crystallization method for cobalt chloride solution

A technology of cobalt chloride and solution, which is applied in the field of crystallization of cobalt chloride solution, can solve the problems of increased production cost, uneven crystal color, low crystallization rate, etc., and achieve the goals of reducing the amount of mother liquor, slow and uniform cooling speed, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

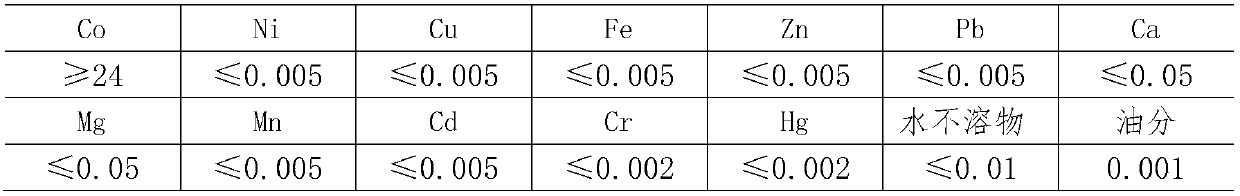

Method used

Image

Examples

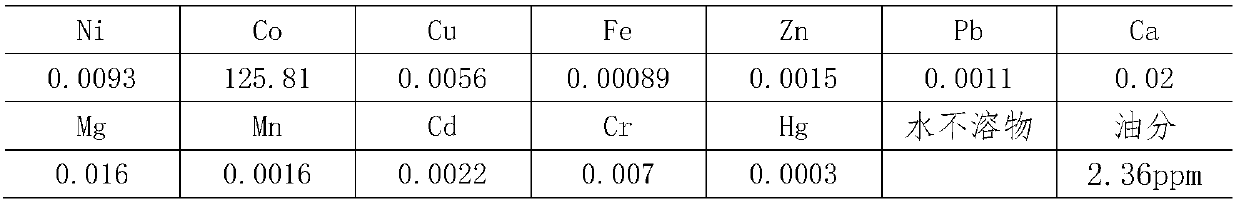

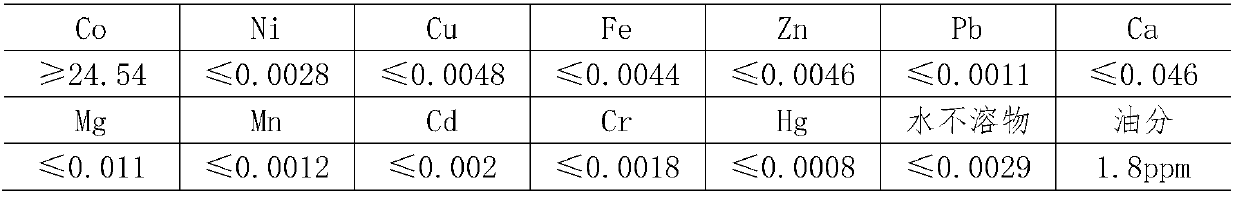

Embodiment 1

[0020] Get the cobalt chloride solution before evaporative concentration in 3.5L table 2 and carry out evaporative concentration in the beaker, when the specific gravity of the cobalt chloride solution after evaporative concentration is 1.48, place the beaker in a water bath and cool down to make the cobalt chloride crystals The grains grow naturally, the cooling rate is 10°C / h, the initial temperature of the water bath is set to 92°C, and the water bath is turned off when the temperature of the water bath drops to 30°C; the crystals are grown naturally at room temperature for 15 hours, and then the chlorinated For the crude cobalt product, the temperature of suction filtration is 25°C; when the temperature of the crude cobalt chloride product drops to 25°C, liquid-solid separation is carried out, and the crude cobalt chloride product through liquid-solid separation is naturally air-dried to obtain the cobalt chloride product, and the chlorine The cobalt chloride product was we...

Embodiment 2

[0024] Get the cobalt chloride solution before evaporative concentration in 3.5L table 2 and carry out evaporative concentration in the beaker, when the specific gravity of the cobalt chloride solution after evaporative concentration is 1.5, place the beaker in a water bath and lower the temperature to make the cobalt chloride crystals The grains grow naturally, the cooling rate is 10°C / h, the initial temperature of the water bath is set to 92°C, and the water bath is turned off when the temperature of the water bath drops to 30°C; the crystals are grown naturally at room temperature for 15 hours, and then the chlorinated For the crude cobalt product, the temperature of suction filtration is 23°C; when the temperature of the crude cobalt chloride product drops to 20°C, liquid-solid separation is carried out, and the crude cobalt chloride product through liquid-solid separation is naturally air-dried to obtain the cobalt chloride product, and the chlorine The cobalt chloride pro...

Embodiment 3

[0028] Get the cobalt chloride solution in 3.5L table 2 before evaporation concentration and carry out evaporation concentration in the beaker, when the specific gravity of the cobalt chloride solution after evaporation concentration is 1.52, place the beaker in a water bath and cool down to make the cobalt chloride crystals The grains grow naturally, the cooling rate is 10°C / h, the initial temperature of the water bath is set to 92°C, and the water bath is turned off when the temperature of the water bath drops to 30°C; the crystals are naturally grown at room temperature for 18 hours, and then the chlorinated crystals are obtained by suction filtration. For the crude cobalt product, the temperature of suction filtration is 20°C; when the temperature of the crude cobalt chloride product drops to 20°C, liquid-solid separation is carried out, and the crude cobalt chloride product through liquid-solid separation is naturally air-dried to obtain the cobalt chloride product, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com