A kind of functional siro compact spinning double-section colorful slub yarn and its production process

A technology of compact siro yarn and slub yarn, which is applied in the field of spinning, can solve the problems of easy breeding of bacteria and unhealthy health, achieve the effect of good cold feeling function, expand market space, and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

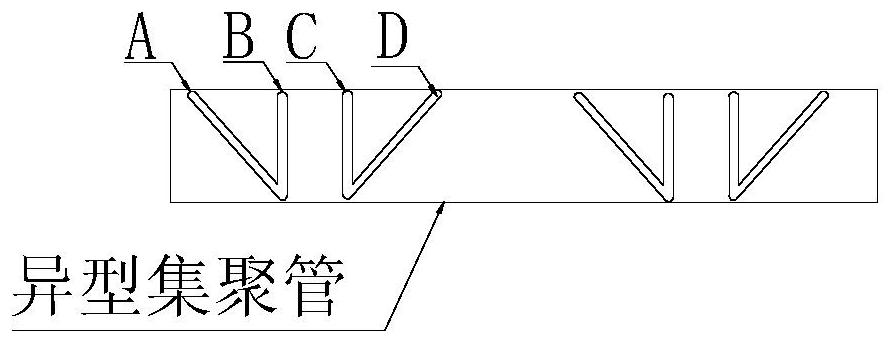

[0027] A functional Siro compact spun double-segment colorful slub yarn, comprising A roving, B roving, C roving and D roving, and the colors of the A roving, B roving, C roving and D roving are different from each other.

[0028] A roving: including ultra-cool polyester fiber and cupro viscose fiber, composed of the following parts by weight: 30-70 parts of ultra-cool polyester fiber, 70-30 parts of cupro viscose fiber; super cool polyester fiber The fiber and cupro viscose fiber are dyed and processed, and the color is consistent;

[0029] B roving: including ultra-cool polyester fiber and cupro viscose fiber, composed of the following parts by weight: 30-70 parts of ultra-cool polyester fiber, 70-30 parts of cupro viscose fiber; super cool polyester fiber The fiber and cupro viscose fiber are dyed and processed, and the color is consistent;

[0030] C roving: including ultra-cold cool nylon fiber and cupro viscose fiber, composed of the following parts by weight: 30-70 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com