Combined bridge capable of prolonging fatigue life of shear connectors and manufacturing method thereof

A technology of fatigue life and manufacturing method, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of fatigue failure, slippage of shear connectors, etc., to improve fatigue life, improve adhesion, and reduce template work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

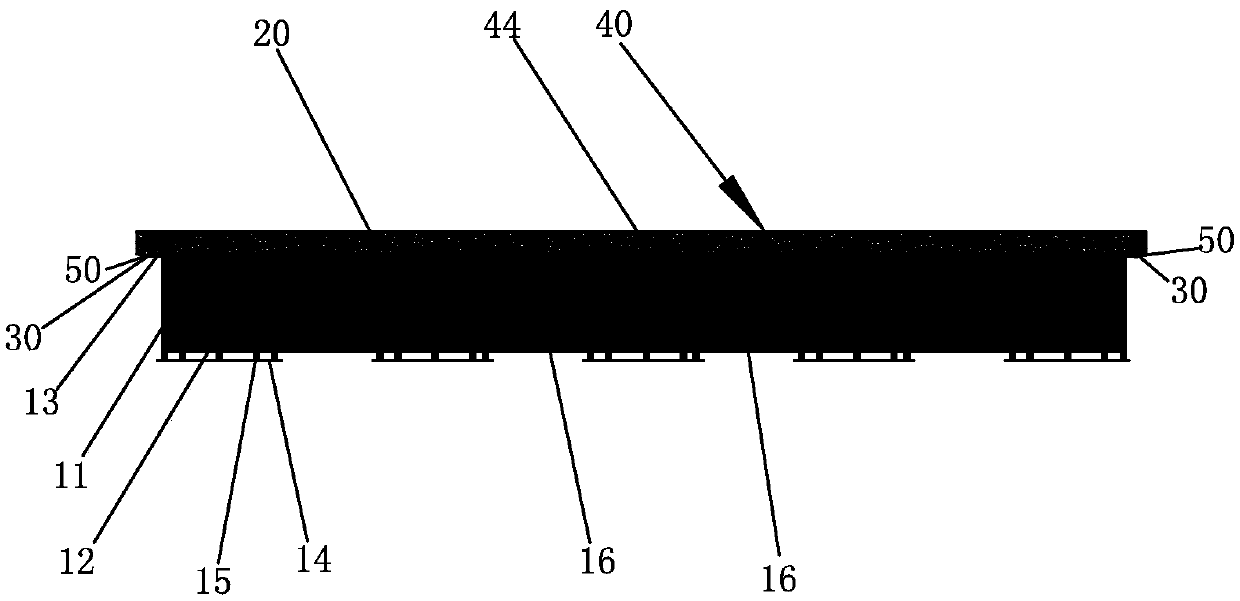

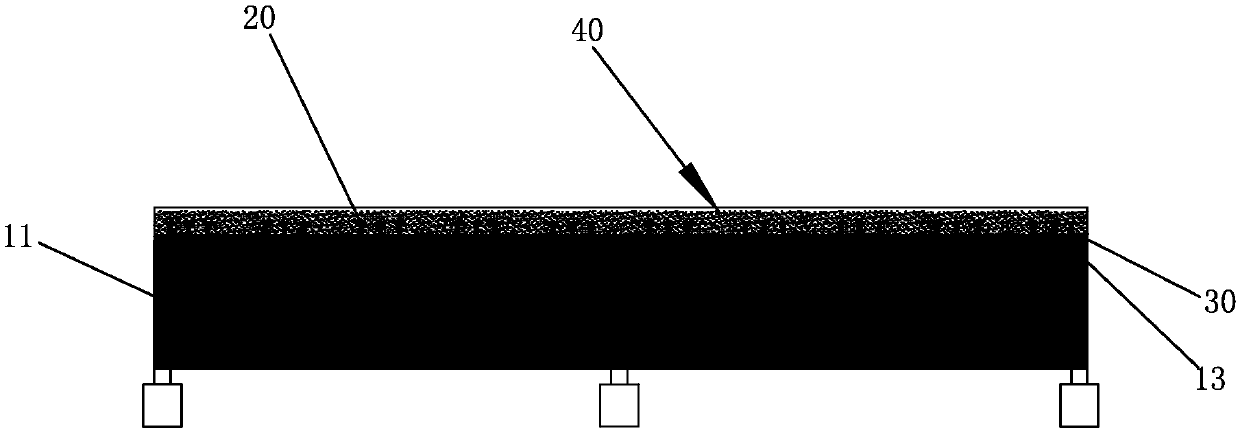

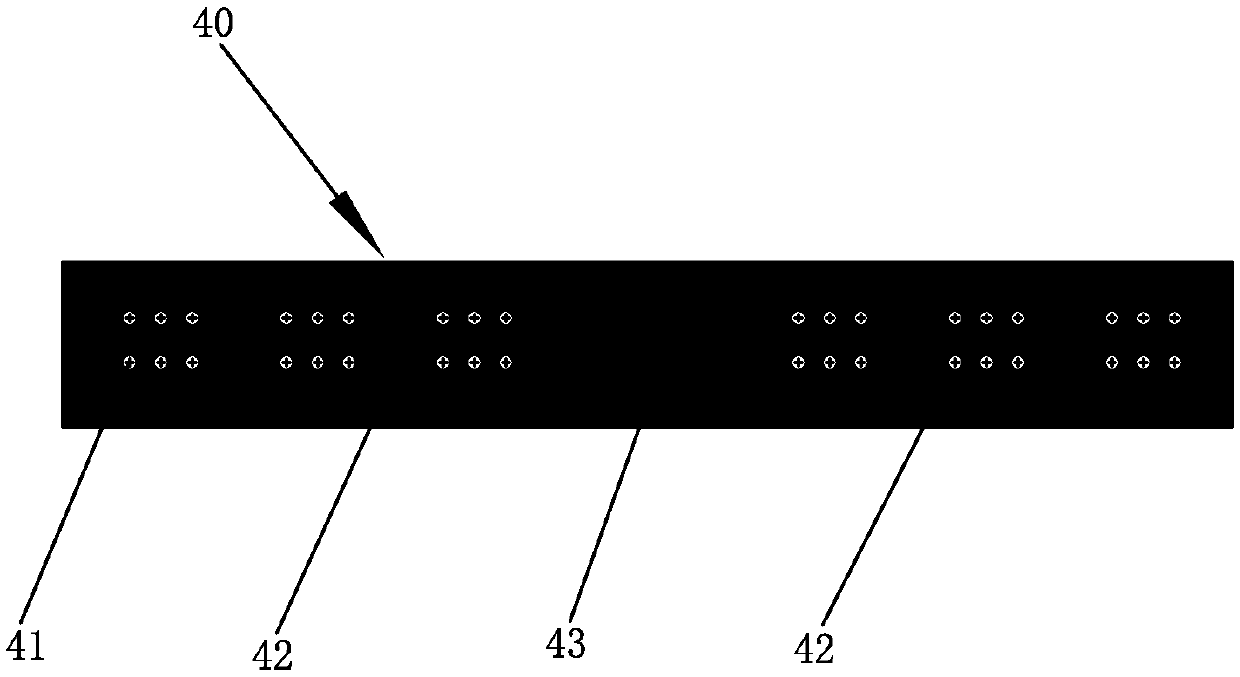

[0038] Please check Figure 1 to Figure 6 , a preferred embodiment of the composite bridge that improves the fatigue life of the shear connectors. The composite bridge that improves the fatigue life of the shear connectors includes several interconnected steel box girders 10, several shear connectors 20. Several epoxy mortar layers 30 and concrete bridge decks 40 .

[0039] The steel box girder 10 includes two steel girders 11 extending along the length direction of the bridge, and several first diaphragms 12 arranged at intervals along the length direction of the bridge, and each first diaphragm 12 is fixedly connected with two steel beams 11 , the top of each steel girder 11 is provided with a support plate 13 extending along the length of the bridge. In this embodiment, the first diaphragm 12 and the steel beam 11 are fixed by welding, and the support plate 13 and the steel beam 11 are also fixed by welding.

[0040] In this embodiment, rubber pads 50 are also provided be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com