Waterway noise reduction device and noise reduction method for refrigeration equipment

A refrigeration equipment and noise reduction technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of poor noise reduction effect, frequent maintenance of muffler, short service life, etc., and achieve the effect of increasing water flow resistance and noise reduction Obvious, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

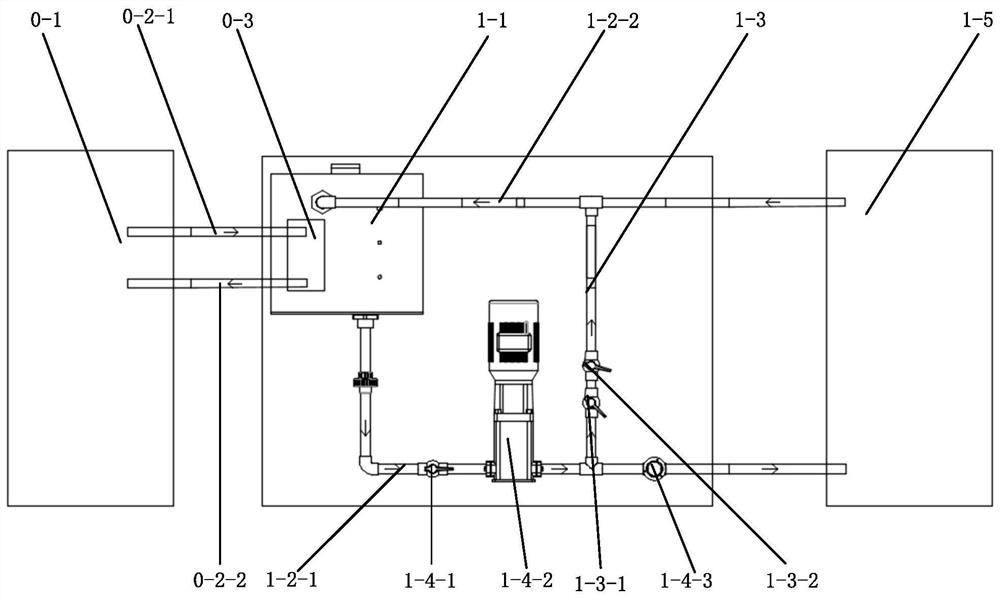

[0025] Design principle of the present invention:

[0026] 1. The principle of water flow noise: the noise of refrigeration equipment mainly comes from the noise of water flow. The noise of water flow is related to the speed of water flow. The larger the pressure difference, the faster the water flow, and the faster the water flow, the louder the noise.

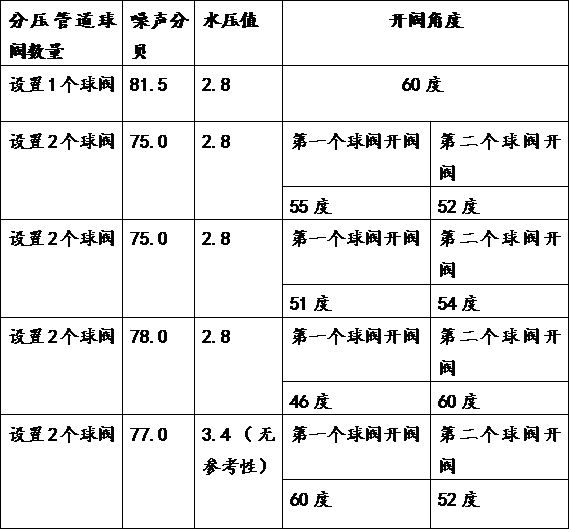

[0027] 2. The principle of water flow slowing down due to resistance of water flow: After the partial pressure pipeline is increased from 1 ball valve to 2 ball valves, the flow diameter of the pipeline between the two ball valves becomes thinner. In order to increase the resistance of the water flow, the increase of the resistance of the water flow makes the speed of the water flow slow down, and the noise of the water flow becomes smaller when the speed of the water flow becomes slower.

[0028] 3. The valve opening angles of the two ball valves in the partial pressure pipeline are smaller than the valve opening angle of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com