Mobile VACOM heat exchanger cleaning method and device

A pre-heat exchanger and cleaning device technology, applied in the field of mobile VACOM pre-heater cleaning method and device, can solve the problems of reducing the fluid flow area, increasing the thermal resistance of the heat exchanger, perforating the heat exchange surface, etc. Save replacement costs, improve safety, compact and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

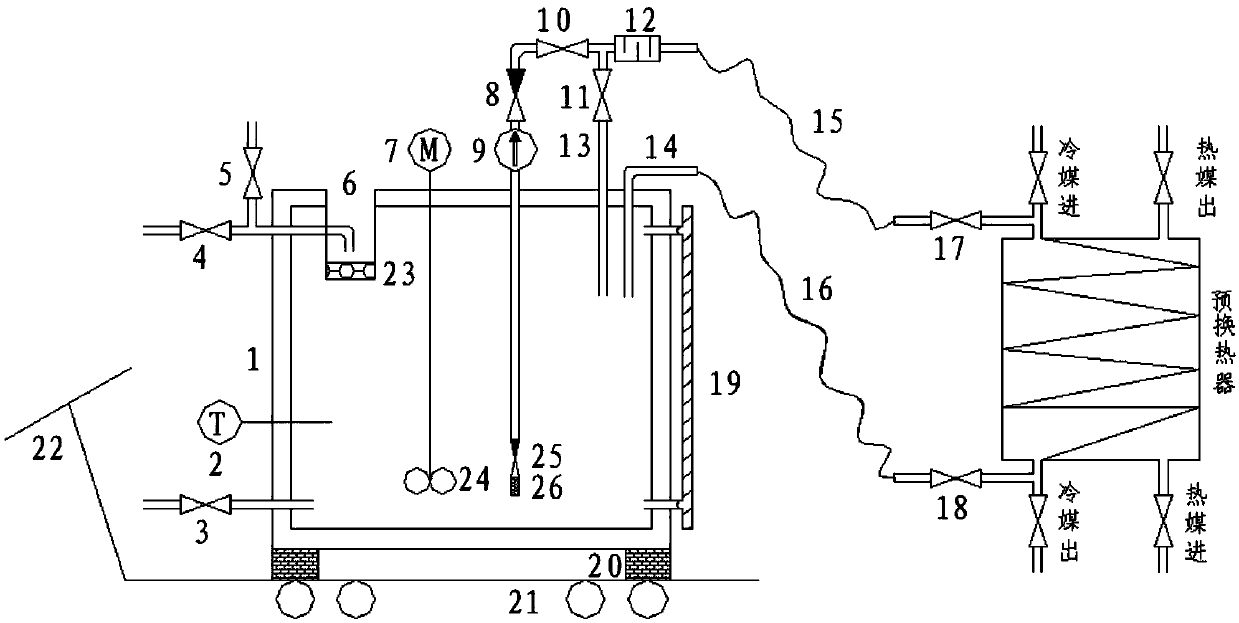

[0039] See figure 1 As shown, the mobile VACOM pre-heat exchanger cleaning device of the present invention includes a mobile cleaning box 1, and the side wall of the cleaning box 1 is provided with an industrial water pipe 4, a condensed water pipe 5 and a discharge pipe 3, and the cleaning box 1 is provided with There are dispensing port 6, agitator 24, liquid inlet pipe 25, recirculation pipe 13 and liquid return pipe 14 connected to pre-heat exchanger 27; The heat exchanger 27 communicates with the liquid inlet pipe 25 and the liquid return pipe 14 through the cleaning liquid inlet hose 15 and the cleaning liquid return hose 16 respectively.

[0040] Wherein, the cleaning liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com