LED device with vertical structure, and manufacturing method thereof

A LED device and vertical structure technology, applied in the direction of semiconductor devices, instruments, electrical components, etc., can solve the problems of slow transfer speed, low efficiency, and difficulty in mass production of micro-LED displays, so as to avoid reunion and solve huge Transfer, the effect of facilitating mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

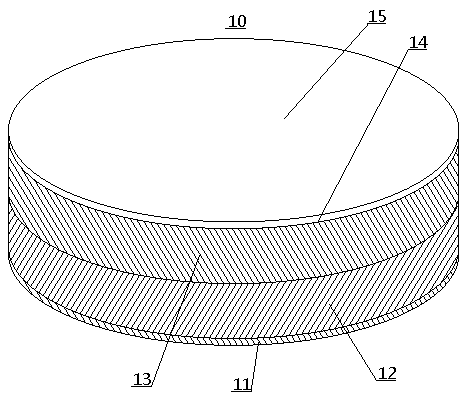

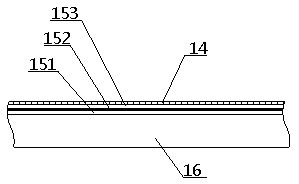

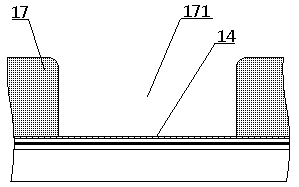

[0039] Such as figure 1 As shown, the LED device 10 is a GaN-based blue light vertical circular LED device with a diameter of 0.3mm (0.03-0.8mm is acceptable), and its film layers are bonding layer 11 and soft magnetic layer from inside to outside. 12. A nonmagnetic metal layer 13, a first electrode 14 and a semiconductor light emitting layer 15. Wherein, the bonding layer 11 is a 5 μm thick tin metal layer (tin alloy layer, indium metal or alloy layer can also be used), the soft magnetic layer 12 is a 40 μm thick iron-nickel alloy layer, and the non-magnetic metal layer 13 is a 40 μm thick copper layer. The metal layer (gold, silver, aluminum metal layer or alloy layer can also be used), the first electrode 14 is a nickel film with a thickness of 100nm; the total thickness of the semiconductor light-emitting layer 15 is 4 μm, which includes an N-type layer (n-GaN) Quantum wells (MQWs) 152 and a p-type layer (p-GaN) 153 as the second electrode of the LED device.

[0040] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com