Bean sheet jelly primary pulp transporting and cooling system

A cooling system and vermicelli technology, applied in the field of edible vermicelli production and manufacturing equipment, can solve the problems of high energy consumption and poor quality of vermicelli products, and achieve the effects of reducing sedimentation, reducing power consumption, and long cooling distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

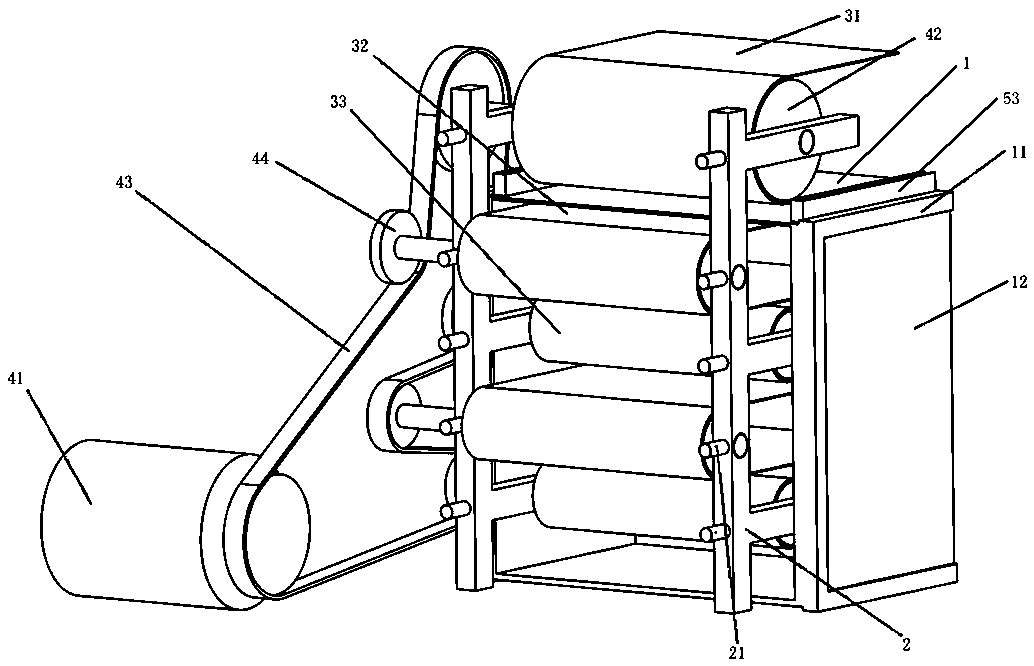

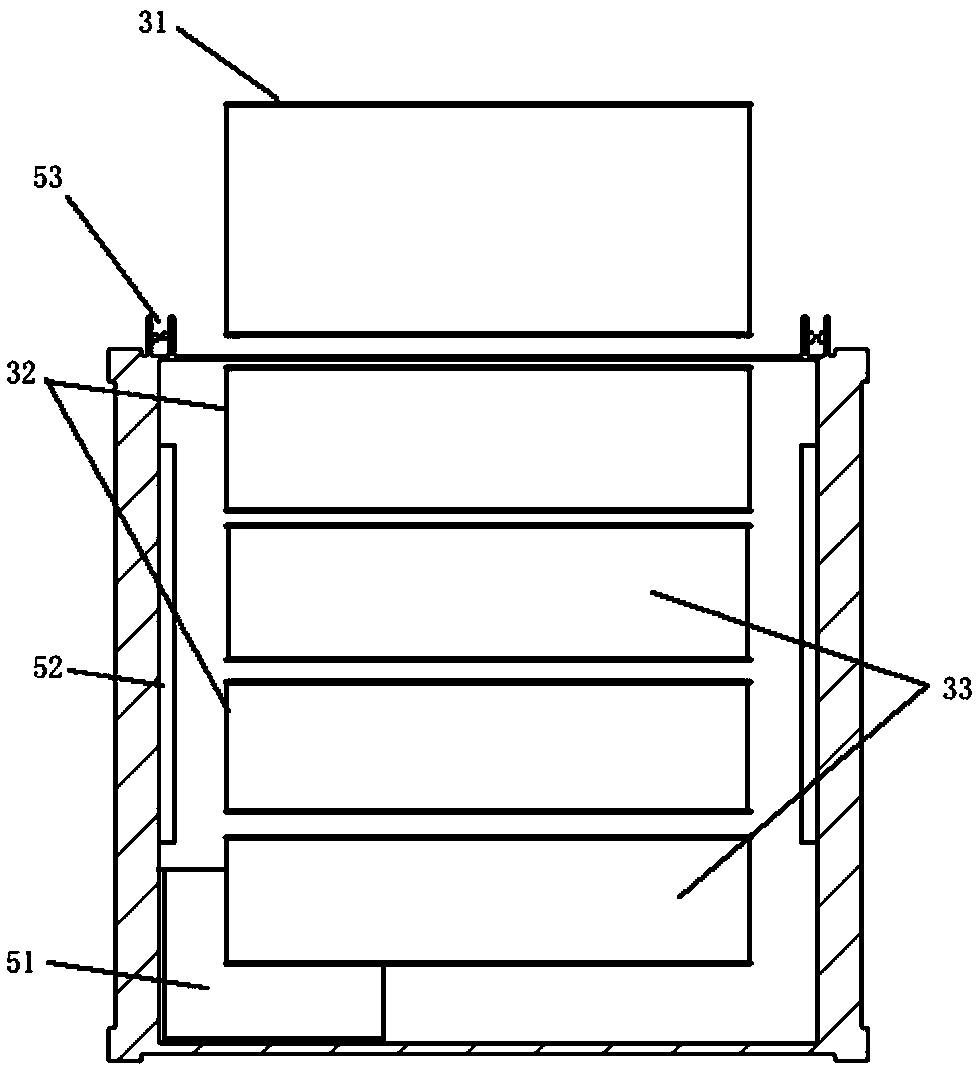

[0038] Such as figure 1 , 2 A kind of vermicelli puree conveying and cooling system shown (only the opening end of cooling chamber 1 is shown in the figure), including cooling chamber 1, conveyor belt support 2 and multi-layer conveyor belts installed in cooperation with cooling chamber 1, and Including a power unit, a cooling device and a control device, the conveyor belt includes a feed conveyor belt 31, a first indoor conveyor belt 32 and a second indoor conveyor belt 33 with two layers, and the conveyor belt is a stainless steel mesh conveyor belt. The cooling chamber 1 is a rectangular parallelepiped structure with one end open in the transverse direction, and the cooling chamber 1 includes a detachable frame 11 connected by bolts and a thermal insulation board 12 embedded in the detachable frame 11 . The feeding conveyor belt is arranged above the top of the cooling chamber 1, the first indoor conveyor belt 32 and the second indoor conveyor belt 33 are vertically spaced...

Embodiment 2

[0043] The technical solution described in this embodiment is similar to that of Embodiment 1, the difference is that:

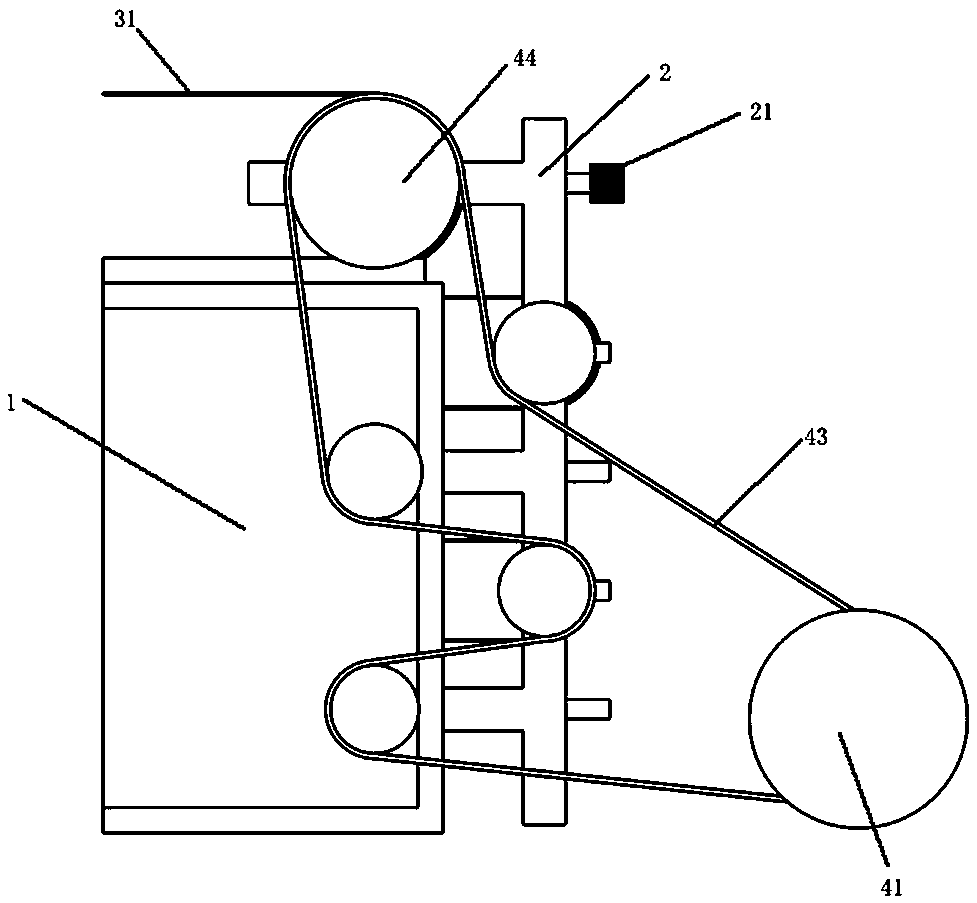

[0044] Such as image 3 As shown, in the present embodiment, the driving rollers 42 are respectively provided with transmission gears 44 meshed with the transmission chain 43; the relationship between the pitch circle diameters of all five transmission gears 44 is that they decrease from top to bottom in the vertical direction. . The transmission gear 44 of the first indoor conveyor belt 32 is engaged with the outside of the closed space of the transmission chain 43, and the transmission gear 44 of the feed conveyor belt 31 and the second indoor conveyor belt 33 is engaged with the inside of the transmission chain 43, thereby realizing the reverse transmission at intervals Effect

[0045] In this embodiment, the control device is connected with the position adjustment device 21 . The position adjustment device in this embodiment has a servo motor at one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com