A method for preparing ultra-high drug-loaded nanoparticles by sequential precipitation complexation coacervation method

A drug-carrying nanotechnology and agglomeration method, which is used in pharmaceutical formulations, active ingredients of heterocyclic compounds, and medical preparations with non-active ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

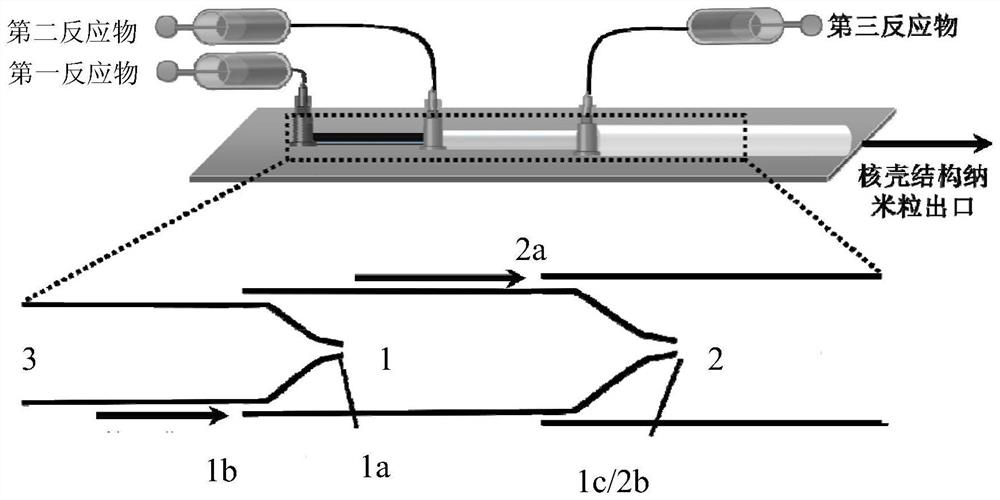

[0100] Such as figure 1 As shown, this embodiment discloses a preparation device for ultra-high drug-loaded nanoparticles, including a first reactor 1 and a second reactor 2; the first reactor includes a first inlet 1a, a second inlet 1b and a first outlet 1c, the second reactor comprises a third inlet 2a and a fourth inlet 2b.

[0101] Optional situation 1: the first inlet 1a is used to add the first reactant, and the first reactant enters the first reactor 1 through the first inlet 1a; the second inlet 1b is used to add the second reactant, and the second inlet 1b is used to add the second reactant. Two reactants along figure 1 The direction of the arrow next to the second inlet 1b enters the first reactor 1; the first reactor 1 is used to accommodate the reaction of the first reactant and the second reactant. Optional situation 2: the first inlet 1a is used to add the second reactant, and the second reactant enters the first reactor 1 through the first inlet 1a; the secon...

Embodiment 2

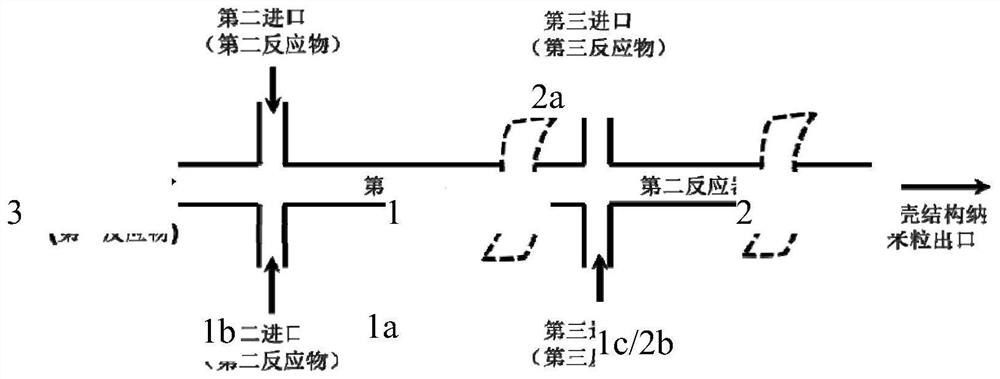

[0105] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is that the pre-accommodating chamber 3 is not used, the first inlet and the first reactor are arranged on the same straight line, and the first reactor and the second reactor are arranged on the same straight line . There are two second inlets, which are respectively perpendicular to the straight line formed by the first inlet and the first reactor. There are two third inlets, which are respectively perpendicular to the straight line formed by the first reactor and the second reactor. The first reactant and the second reactant enter the first reactor through the first inlet and the second inlet respectively, or the first reactant and the second reactant enter the first reactor through the second inlet and the first inlet respectively. Interchanging the piping of the first reactant and the second reactant into the first reactor does not affect the production of nanoparticles. This exa...

Embodiment 3

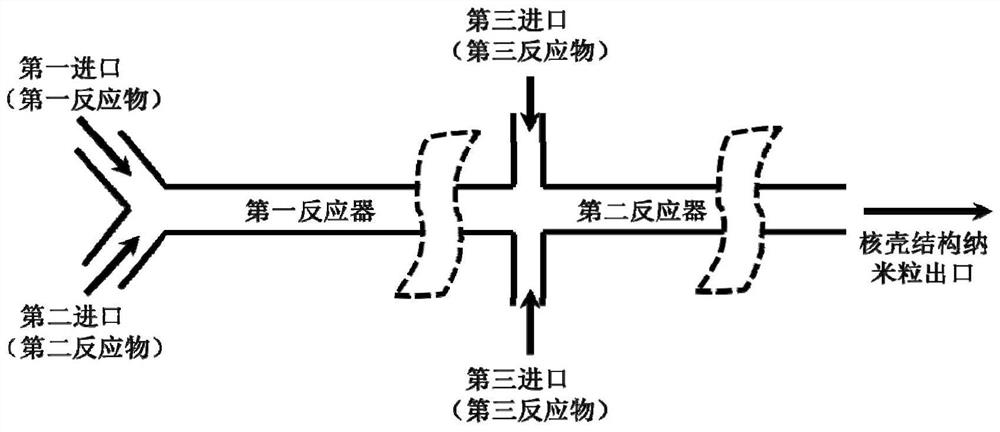

[0107] Such as image 3 As shown, the difference between this embodiment and embodiment 2 is that there is one second inlet, and the first inlet and the second inlet are respectively obliquely connected to the first reactor, forming an incident angle with the first reactor ( 0~180 degrees), and the rest are the same. The first reactant and the second reactant enter the first reactor through the first inlet and the second inlet respectively, or the first reactant and the second reactant enter the first reactor through the second inlet and the first inlet respectively. Interchanging the piping of the first reactant and the second reactant into the first reactor does not affect the production of nanoparticles. This example is directed to a reactor prepared by using polymer materials such as PDMS. The dashed part in the middle indicates that the length of the reactor can be adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com